Plastic Bag Making Machine, SD-A

Plastic Bag MakingMachine

The plastic bag making machine is used for theproduction of twofold or multifold three-margin-sealed multiple membrane bagswhich take BOPP, PET, CPP, PE, nylon, aluminum foil, and paper as basicmaterials. The equipment is easy to run and its product has a smooth surfaceand beautiful shape. With its high thermal sealing intensity and highproduction speed, it is the ideal packing bag manufacturing device.

Features of Plastic Bag MakingMachine

1. The plastic bag making machine uses a computer controllingsystem which is of industry level and all the parameters use CRT real-time display.

2. The bag-making speed, bag-making length, temperature, counting, punching andconveyor quantity of doubling finished products, etc. can be preset.

3. The releasing tension of the plastic bag making machine can be controlled bya fully automatic adjustable magnetic powder constanttension control system.

4. It offers LPC automatic deviation-rectifying and double photoelectrictracking, a new type of pressure-lifting 6 times conveying function, andcomputer 16-route PID constant temperature control.

5. The plastic bag making machine offers pneumatic multi-functional punching,automatic collecting of cut rim charge, and electrostatic elimination.

6. The technology of self supporting and self-sealing device the machine offersis in the lead at home, which can truly make a bag by one machine with multiplefunctions.

TechnicalSpecifications of the Plastic Bag Making Machine, SD-A

| Max. Length | 50-450mm |

| Max. Width | 50-600mm |

| Sealing Width | 6-20mm |

| Bag Output | 30-110times/min |

| Total Power | 25kw |

| Weight | 5800kg |

| Boundary Dimensions | L9060*W1200*H1680mm |

As a China-based plastic bag making machine manufacturer, ShenⅦ also supplies paper cup forming machine, non woven bag handle sealingmachine, PE film blowing machine, slitting machine, and much more.

Links:https://www.globefindpro.com/products/92963.html

-

201 Threaded Stainless Steel Tube

201 Threaded Stainless Steel Tube

-

301 Stainless Steel Tube

301 Stainless Steel Tube

-

430 Round Stainless Steel Tube

430 Round Stainless Steel Tube

-

316L Stainless Steel Tube

316L Stainless Steel Tube

-

Multifunction Slitting Machine

Multifunction Slitting Machine

-

Dry Laminating Machine

Dry Laminating Machine

-

Stainless Steel Sheet

Stainless Steel Sheet

-

304 Threaded Steel Tube

304 Threaded Steel Tube

-

Non Woven Bag Handle Sealing Machine

Non Woven Bag Handle Sealing Machine

-

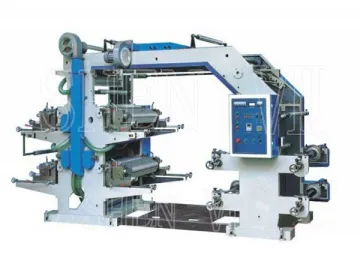

4 Color Flexographic Printing Machine

4 Color Flexographic Printing Machine

-

Plastic Bag Making Machine, FQ-B

Plastic Bag Making Machine, FQ-B

-

Non Woven Bag Making Machine

Non Woven Bag Making Machine