Full Auto Laminating Machine

Full Auto LaminatingMachine

The full auto laminating machine is applied to BOPP, PET,CPP, PVCD, aluminum-plated film, and aluminum-tissue,as well as the compound film and paper with the same properties. Its mechanicalspeed is 70m/min.

Features of Full Auto LaminatingMachine

1. The main transmission unit of thefull auto laminating machine uses alternating current variable frequency vectorto control the motor. The spreading roller and hot drum are synchronized anduse swing arms to control tightness and looseness of the film in the ovenchannels.

2. Group 1 and 2 feeders use double working stations to pre-start, pneumaticedge correction device, and automatic tension control.

3. The anilox rollers usescraper for scrapping and spreading, and the spreading thickness can be freelyadjusted through the scrapper. The rubber roller uses a double air cylinder toincrease the pressure, and the pressure can be freely adjusted.

4. An intelligent thermocontroller is used for temperature control of the oven channel. Thematerial protecting roller and the hot drum canrotate synchronously.

5. The laminating hot drum is heated through the heat conducting oil, whichachieves uniform heating effect and low power consumption. The press rolleruses a double air cylinder, and the pressure is adjustable.

6. The material receiving device adopts double working station to pre-start. Atorque motor is used for rewinding.

Technical Specifications of the Full Auto Laminating Machine

| Technical Model | GF-B11100 |

| Layers of Complex | 2 layer |

| Compounding Width | 1100mm |

| Suitable Diameter | 600mm |

| Adjustable Speed | 50-120m/min |

| Maxi Adjustable Temp. of the Oven | 80 ℃ |

| Maxi Adjustable Temp. of the Heat Beat | 70 ℃ |

| Tension's Equivalent Extension Ratio | ≤1/1000 |

| Total Power | 50KW |

| Weight | 4500kg |

| Overall Dimensions (L×W×H) | 9000×1900×2600 |

We are a China-based full auto laminatingmachine manufacturer. We also supply paper cup machine, film blowing machine,slitting machine, printing machine, and much more.

Links:https://www.globefindpro.com/products/92986.html

-

Stainless Steel Flat Bar

Stainless Steel Flat Bar

-

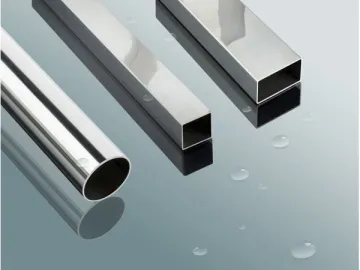

316 Stainless Steel Tube

316 Stainless Steel Tube

-

Plastic Bag Making Machine, SB-M

Plastic Bag Making Machine, SB-M

-

304 Embossed Steel Tube

304 Embossed Steel Tube

-

316 Embossed Steel Tube

316 Embossed Steel Tube

-

Square Stainless Steel Pipe

Square Stainless Steel Pipe

-

Stainless Steel Pipe Tee

Stainless Steel Pipe Tee

-

Plastic Bag Making Machine, RQ-D

Plastic Bag Making Machine, RQ-D

-

201 Embossed Stainless Steel Tube

201 Embossed Stainless Steel Tube

-

201 Stainless Steel Tube

201 Stainless Steel Tube

-

Stainless Steel Sphere

Stainless Steel Sphere

-

430 Square Stainless Steel Tube

430 Square Stainless Steel Tube