Plastic Crusher

Plastic Crusher

Features of Plastic Crusher

1. Our plastic crusher provides elegant appearance with firm painting inwell-matched colors, easy operation and safety, saves electricity, and has wideapplications. The high quality products are offered at reasonable prices.

2. The machine comes with separate design of feeding hopper, crushing chamber,and sieve, which facilitate easy loading and unloading. The buffer chamber and the feeding portwith shade design prevent material oil spill.

3. The plastic crusher offers the motor with an overload protection device, andthe power supply with an interlocking protection system. The belt pulley,designed with a protective cover, utilizes a safety catch for cleaning.

4. The wall of the crushing chamber provides double-layer insulation, ensuringlow noise and low vibration.

Use of Plastic Crusher

The plastic crusher is suitable for crushing hard die materials and bootlast materials, includingsuch plastics as PS, ABS, EVA, TPU, PVC, PE, PP and TPR, etc. What’s more, theplastic crushing equipment is applicable to nylon, engineering plastics, calendered film, thin sheets,soft materials, pipe materials, as well as other waste products and plasticinjection heads.

Technical Parameters of Plastic Crusher

| Model | Motor power (kw ) | Scope of application | Crushing capacity (kg/h) | Crushing chamber caliber (mm) | Stationary Cutter | Rotary Cutter | Weight (kg) |

| KP300 | 7.5 | Workpiece materials, waste product materials, hard die materials, leftover materials, mineral water bottles, plastic buckets, plastic pots, etc. | 100-250 | 300*400 | 2 | 6 | 450 |

| KP400 | 11 | 200-400 | 400*500 | 2 | 6 | 700 | |

| KP500 | 18.5 | 300-600 | 500*600 | 2/2 | 6/16 | 1000 | |

| KP600 | 22 | 400-700 | 600*700 | 2/2 | 6/16 | 1300 | |

| SP500 | 22 | 200-500 | 600*700 | 4 | 6 | 900 | |

| SP600 | 22 | 300-600 | 700*800 | 4 | 6 | 1200 | |

| SP800 | 30 | 400-800 | 800*900 | 4 | 6 | 150 |

Links:https://www.globefindpro.com/products/93026.html

-

Rubber Sole Moulding Machine

Rubber Sole Moulding Machine

-

Double Color Rubber Injection Molding Machine

Double Color Rubber Injection Molding Machine

-

TR/TPR/TPU/PVC Thermoplastic Molding Machine

TR/TPR/TPU/PVC Thermoplastic Molding Machine

-

Double Color EVA Foam Injection Molding Machine

Double Color EVA Foam Injection Molding Machine

-

EVA Flat Sole Shaping Molding Machine

EVA Flat Sole Shaping Molding Machine

-

PVC TPR Overshoe Disc Injection Machine

PVC TPR Overshoe Disc Injection Machine

-

Silicon Steel Coil

Silicon Steel Coil

-

Round Welded Steel Pipe

Round Welded Steel Pipe

-

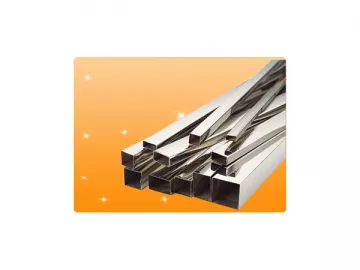

Decorative Stainless Steel Pipe

Decorative Stainless Steel Pipe

-

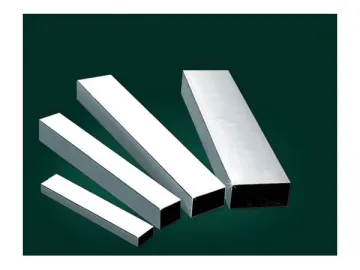

Rectangular Stainless Steel Pipe

Rectangular Stainless Steel Pipe

-

Structural Steel Pipe

Structural Steel Pipe

-

Embossed Welded Stainless Steel Pipe

Embossed Welded Stainless Steel Pipe