Single Color EVA Foam Injection Molding Machine

Single Color EVA FoamInjection Molding Machine

The single color EVA foam injection molding machine is equipped with two fullautomatic and high-efficiency injectors, combined with high-performance mouldclamping system and PC control system. Using EVA as the raw material, theinjection molding machine can produce midsoles,soles and various kinds of EVA foaming products.

1. Injection system of Injection Molding Machine

The measuring mechanism whichuses potentiometer detection, along with PLC and PC,can compute and control material quantity precisely. The two injectors of theEVA foam injection molding machine utilize the worm gear reducer and the brakemotor, running at a high speed controlled by a converter. The orientationsystem, using ultrasonic linear transducer, provides high accuracy.

2. Mould clamping system of Injection Molding Machine

The two-step mouldopening/clamping mechanism comes with a detection device for full mould opening. Large mould design, with high compatibility,enables the flexible use of a variety of moulds.

Technical Parameters of Injection Molding Machine

| Item | Unit | LD2002S1-C | LD2002S2-C | LD2003S1-C | LD2003S2-C | LD2004S2-C | LD2006S2-C | LD2008S2-C | LD2010S2-C | LD-260-S2 |

| Mould-opening |

|

|

|

|

|

|

|

|

|

|

| No. of work stations | 2 | 2 | 3 | 3 | 4 | 6 | 8 | 10 | 2 | |

| Clamping force | T | 170 / 200 | 170 / 200 | 170 / 200 | 170 / 200 | 170 / 200 | 170 / 200 | 170 / 200 | 170 / 200 | 250 |

| Mould holder dimensions | mm | 290X500X2 / 290X550X2 | 290X500X2 / 290X550X2 | 290X500X2 / 290X550X2 | 290X500X2 / 290X550X2 | 290X500X2 / 290X550X2 | 290X500X2 / 290X550X2 | 290X500X2 / 290X550X2 | 290X500X2 / 290X550X2 | 330X600 |

| Mould height | mm | 100-270 | 100-270 | 100-270 | 100-270 | 100-270 | 100-270 | 100-270 | 100-270 | 100-270 |

| Max. mould opening stroke | mm | 350 (mould thickness) | 350 (mould thickness) | 350 (mould thickness) | 350 (mould thickness) | 350 (mould thickness) | 350 (mould thickness ) | 350 (mould thickness) | 350 (mould thickness) | 420 (mould thickness) |

| Independent temperature control | No. | 4*4 | 4*4 | 4*4 | 4*4 | 4*4 | 4*4 | 4*4 | 4*4 | 4*4 |

| Heat way |

| Heater | Heater | Heater | Heater | Heater | Heater | Heater | Heater | Heater |

| Heating power | KW | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 |

| Quantity of injection gun | 1 | 2 | 1 | 2 | 2 | 2 | 2 | 2 | 1 | |

| Charging screw diameter | mm | 60 / 65 / 70 | 60 / 65 / 70 | 60 / 65 / 70 | 60 / 65 / 70 | 60 / 65 / 70 | 60 / 65 / 70 | 60 / 65 / 70 | 60 / 65 / 70 | 75 |

| Max. injection capacity | cm3 | 905 980 1060 | 905 980 1060 | 905 980 1060 | 905 980 1060 | 905 980 1060 | 905 980 1060 | 905 980 1060 | 905 980 1060 | 1200 |

| Rotating speed of charging screw | Rpm | 0-260 adjustable | 0-260 adjustable | 0-260 adjustable | 0-260 adjustable | 0-260 adjustable | 0-260 adjustable | 0-260 adjustable | 0-260 adjustable | 0-260 adjustable |

| No. of temperature control sections of material tube | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Injection pressure | Bar/cm2 | 1130 | 1130 | 1130 | 1130 | 1130 | 1130 | 1130 | 1130 | 1130 |

| Electric heating consumption of injection unit | KW | 5.75 | 11.5 | 5.75 | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 | 5.75 |

| Electric heating consumption of heating plate | KW | 25.6 | 25.6 | 38.4 | 38.4 | 51.2 | 76.8 | 102.4 | 128 | 32 |

| Motor of hydraulic pressure unit | KW | 37 | 18.5 | 37 | 18.5 | 37 | 37 | 37 | 37 | 37 |

| Total power consumption | KW | 53 | 75 | 67 | 93 | 106 | 143 | 156 | 182 | 53 |

| Dimension of machine | m | 3.5X4.5X2.75 | 3.5X4.5X2.75 | 4.4X4.5X2.75 | 4.4X4.5X2.75 | 5.3X4.5X2.75 | 7X4.5X2.73 | 9.2X4.5X2.75 | 12X4.5X2.7 | 3.5X1.5X2.75 |

| Weight of machine | Tonnage | 9 | 11 | 14 | 16 | 19 | 26 | 33 | 38 | 12 |

3. Computer-control system of Injection Molding Machine

The PLC control module works through a graphic display interface to show allmonitoring information and setting conditions: material input amount, injection temperature, mould temperature, operation time, output, mould data, etc. All operation processes can be controlled and performed on the touchscreen. Besides, the operation instructions are easy to be learned.With the man-machine interface, maintenance and malfunction detection of the single colorEVA foam injection molding machine becomes easy and time saving. Multistagecode control enables settings for different management levels from operators, maintenance men to managers, whichcan avoid man-made negligence and keep production information safe.

4. Hydraulic system (Oil pressure system) of Injection Molding Machine

The use of proportional control valve together with the computer control systemenables the hydraulic system of the injection molding machine to accuratelykeep control of the flow of multistage pressureand speed. Pumps are designed to keep noise down and improve efficiency.

Lida Machine is aprofessional single color EVA foam injection molding machine manufacturer in China. Inaddition, we offer mini EVA foaming machine, rubber sole moulding machine, vertical color mixing machine, andmore.

Links:https://www.globefindpro.com/products/93055.html

-

CR Adhesive Foam Pads

CR Adhesive Foam Pads

-

CR Die Cut Foam Tape

CR Die Cut Foam Tape

-

Double Sided EVA Foam Tape

Double Sided EVA Foam Tape

-

Flat Sole Printing Machine

Flat Sole Printing Machine

-

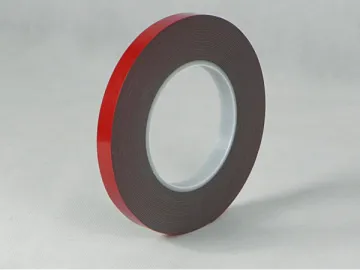

Gray Acrylic Tape

Gray Acrylic Tape

-

Double Sided PVC Foam Tape

Double Sided PVC Foam Tape

-

Color Coated Steel Strip

Color Coated Steel Strip

-

Vertical Color Mixing Machine

Vertical Color Mixing Machine

-

Color Coated Steel Sheet

Color Coated Steel Sheet

-

Hot Dipped Galvanized Steel Strip

Hot Dipped Galvanized Steel Strip

-

Hot Dipped Galvanized Steel Sheet

Hot Dipped Galvanized Steel Sheet

-

Fully Automatic Single Color PVC Air Blowing Injection Machine

Fully Automatic Single Color PVC Air Blowing Injection Machine