1200D Capsule Filling Machine

1200D Capsule Filling Machine

Features

1. The fully automatic capsule filling machine has been improved the innerdesign turret, and TIANHONG imports 90 pcs beeline bearing for each machine from Japan directly,so this can assure a longer usage life and precision of our capsule fillingmachine, comparing to other manufacturers in China that use only 40 pcsbeeline bearings and the other 50 pcs are equipped with copper cover.

2. The working station cam runs under the goodlubricating condition, and maintains the inner lubrication of cam slot to afull extent, increasing the pressure pulverization oil pump, thus extending theoperation life of the spare parts.

3. Theautomatic capsule filling machine adopts enlarged cam, TIANHONG has become theone who matched the cam of RU100 to RU 100, while it enhances the stability ofthe machines and extends the life of the machine to a great extent. Othermanufacturers in China use cam of RU 83 to RU 83.

4. Ourautomatic capsule filler is controlled by the computer. It has stepless timing with the frequencyconversion and thenumeral showing makes an easy operation and clear appearance.

5. Thegood capsule applicability makes a high capsules qualified rate more than 99%. It can be filled both with theChinese traditional medicine and the western medicine.

6. Our capsule filling machine adds the extrafunction of capsule control switch to control the capsule outside of themachine making it safer and quicker.

7. It is designed with click-moving control system to make easier operation and clearness. Themulti-bore dosing brings a precision dosage.

MainStructure

Our capsule filling machine consists of touchscreen control, closed turret, capsule magazine, filling chamber, capsulejoining station, dosing disk level adjusting switch, flaw capsule rejectionstation, filled capsule ejection station and more.

Technical Parameters of our 1200D Capsule FillingMachine

| Model | NJP-200 | NJP-400 | NJP-800 | NJP-1000 | |

| Capacity | 12000capsules/hr | 24000capsules/hr | 48000capsules/hr | 72000capsules/hr | |

| No. of Segment Bores | 2 | 3 | 6 | 9 | |

| Net Weight | 600kg | 750kg | 800kg | 900kg | |

| Dimension | 700*800*1700mm | 700*800*1700mm | 860*960*1800mm | 960*1000*1900mm | |

| Power Supply | 220/380V, 3 PHASE, 50/60 HZ (For customer to designate) | ||||

| Main Motor | 1.1kw | 1.1kw | 1.1kw | 1.1kw | |

| Vacuum Power | 0.75kw | 0.75kw | 1.5kw | 1.5kw | |

| Vacuum Pump | 20m 3 /h 0.04-0.08Mpa | 20m 3 /h 0.04-0.08Mpa | 20m 3 /h 0.04-0.08Mpa | 40m 3 /h 0.04-0.08Mpa | |

| Dust Collector | 17.6Kpa 180 m 3 /h | 17.6Kpa 180 m 3 /h | 17.6Kpa 180 m 3 /h | 24.5Kpa 210 m 3 /h | |

| Noise | < 80DB (A) | ||||

| Capsule Size | 00#-4# | 00#-4# | 00#-4# | 00#-4# | |

| Filling Error | ±2.5%-3.5% | ±2.5%-3.5% | ±2.5%-3.5% | ±2.5%-3.5% | |

Ourcompany is a specialized capsule filling machine manufacturer in China. We alsooffer semi automatic capsule filling machine, Transparent Film Packing Machine,polishing machine, cartoning machine, and much more.

Links:https://www.globefindpro.com/products/93222.html

-

800 Capsule Filling Machine

800 Capsule Filling Machine

-

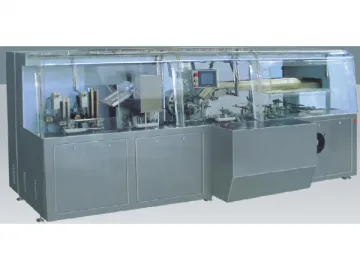

High Speed Cartoning Machine

High Speed Cartoning Machine

-

Capsule Filling Machine

Capsule Filling Machine

-

3500 Capsule Filling Machine

3500 Capsule Filling Machine

-

1250 PP Membrane Filter Press

1250 PP Membrane Filter Press

-

470 CGR Filter Plate

470 CGR Filter Plate

-

Semi-Automatic Capsule Filling Machine, DTJ-V

Semi-Automatic Capsule Filling Machine, DTJ-V

-

Automatic Blister Packaging Machine

Automatic Blister Packaging Machine

-

Transparent Film Packing Machine

Transparent Film Packing Machine

-

Corrosion and Oil Resistant Cable

Corrosion and Oil Resistant Cable

-

High Voltage Cable

High Voltage Cable

-

Elevator Traveling Cable

Elevator Traveling Cable