2000 Capsule Filling Machine

2000 Capsule FillingMachine

MainFeatures of our Capsule Filling Machine

1. In order to improve quality andoperation efficiency, by our innovations and reconstructions, the capsule filling machine is enlarged, to be larger than similarproducts by 9cm.

2. Uses enlarged cam and adopts the RU125 to RU100 cam to guarantee the quality. Although the cost isincreasing, the machine is much more stablity and life of machinery areimproved greatly.

3. Our capsule fillingmachine enlarges the design of dosing disk, increases the 3cm based on original design and it makesdose filling accuracy much improved and better than China national standards.

4. This capsule filler measures based on lower place,3D adjustment and reduces natural deforms on measurement discs and copper sauces. Furthermore, uniformclearances between parts, reduces leakage of powder and makes it easy to clean and assembly.

5. Our capsule fillingmachine improves turntable design, uses original Japanese straightoil-free bearings of 90 pcs to ensure accuracy and service life. Other manufacturers use only 40turntable bearings, and 50 pcs are installed with copper which is easily wearand tear and difficult to replace.

6. The capsule filler adopts man-machine interface,complete functions and cam eliminate faults such as lacking of capsule andmaterials. While the machine is run out of capsules and powder, it will stopautomatically with alarm and it will display on the touch screen theoutput of capsules with materials.

WorkingDescriptions of our Capsule Filling Machine

1. The empty gelatin capsules are fed from astorage hopper to the rectifier and inserted with the aid of vacuum into one ofthe 10 sets of carrier segments and each carrier segment holds 18 emptycapsules.

2. The carrier segment'supper holder holding the caps is now lifted separation of cap and body isassisted by vacuum.

3. The upper holder startsretracting while the lower proceeds to the dosing station of capsule filling machine.

4. Complete retraction of the upper holder is doneat this station.

5. Powder slug is insertedinto the capsule body, if thereis no capsule body held at the lower holder, the powder slug will be furtherpushed downward and collected in a receiver tray.

6. The ejection of un-separated capsule or theup-side-down capsule caps is performed with an aid of upward stroking rods.

7. The upper holder of our capsulefilling machine starts moving outward to theposition above the lower holder.

8. At this station, whileupper and lower holders are closely matched the capsule bodies are pushedupward into the caps by steel rods.

9. Now the closed capsulesarriving at this capsulefiller station will push upward again by the other steel rods and leave the carrier segment.

10. Carrier segment isvacuum-cleaned and proceeds to the capsule insertion station.

Technical Specification of our Capsule FillingMachine

| Model | NJP-1200 | NJP-1500 | NJP-1800 | NJP-2000 | |

| Capacity | 72000capsules/hr | 10800capsules/hr | 120000capsules/hr | 120000capsules/hr | |

| No. of Segment Bores | 9 | 16 | 16 | 18 | |

| Net Weight | 1100kg | 1100kg | 1100kg | 1100kg | |

| Dimension | 960*1000*1900mm | 1180*1300*1900mm | |||

| Power Supply | 220/380V, 3 PHASE, 50/60 HZ (can be customized) | ||||

| Main Motor | 1.5kw | 2.2kw | 2.2kw | 2.2kw | |

| Vacuum Power | 2.2kw | 2.2kw | 2.2kw | 4kw | |

| Vacuum Pump | 40m 3 /h 0.04-0.08Mpa | 20m 3 /h 0.04-0.08Mpa | 20m 3 /h 0.04-0.08Mpa | 40m 3 /h 0.04-0.08Mpa | |

| Dust Collector | 24.5Kpa 210 m 3 /h | ||||

| Noise | < 80DB (A) | ||||

| Capsule Size | 00#-4# | 00#-4# | 00#-4# | 00#-4# | |

| Filling Error | ± 2.5%-3.5% | ± 2.5%-3.5% | ± 2.5%-3.5% | ± 2.5%-3.5% | |

As a professional capsule filling machinemanufacturer and supplier in China,we at Tianhong also offer polishing machine, Transparent Film Packing Machine,cartoning machine, and semi automatic capsule filling machine, among others.

Links:https://www.globefindpro.com/products/93233.html

-

Automatic Film Packing Machine

Automatic Film Packing Machine

-

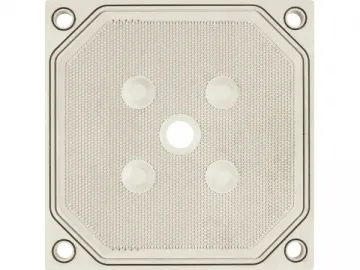

630 CGR Filter Plate

630 CGR Filter Plate

-

Blister Packing Machine

Blister Packing Machine

-

1000 Capsule Filling Machine

1000 Capsule Filling Machine

-

Semi-Automatic Capsule Filling Machine, DTJ-C

Semi-Automatic Capsule Filling Machine, DTJ-C

-

1500 PP Membrane Filter Press

1500 PP Membrane Filter Press

-

Automatic Blister Machine

Automatic Blister Machine

-

1200 CGR Filter Plate

1200 CGR Filter Plate

-

1200C Capsule Filling Machine

1200C Capsule Filling Machine

-

470 CGR Filter Plate

470 CGR Filter Plate

-

1250 PP Membrane Filter Press

1250 PP Membrane Filter Press

-

3500 Capsule Filling Machine

3500 Capsule Filling Machine