2000 Chamber Filter Press

2000 Chamber Filter Press

Features

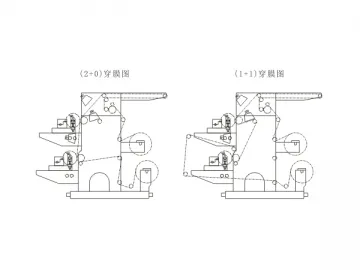

The 2000 chamber filter press is controlled by theelectrical panel. It adopts hydraulic pressing system with manual plateshifting method, which ensures easy operation and maintenance. The drip traysystem can also be added to help collecting filtrate.

Applications

Our chamber filter press is a pieceof equipment used for separating the sludge, slurry or fluid containing solids.It consists of a series of plates covered with filter cloth or filter screens,and a manual or hydraulic closure device required. The closure devicepresses the plates together to create a sealed unit, and then the sludge istrapped between the plates, allowing the filtered liquid to be discharged.

The chamber filter press is commonly adopt in the solid-liquid separationprocess of coal washing, sewage treatment, and can be widely used in themetallurgy, foodstuff, energy source, alcohol, textile, pharmaceutical,inorganic salt, chemical, light industries, as well as the field of environmentprotection.

Specifications

| Place of Origin | Shandong, China (Mainland) |

| Brand Name | Zhongda Bright |

| Type | General hydraulic |

| Plate type | Membrane Type |

| Plate Size | 2000x2000mm |

| Feeding type | Center Feed |

| Max Feeding Pressure | 0.6~1.0 Mpa |

| Max squeezing pressure | 1.0~1.6 Mpa |

| Filtration area | 500~1000 M2 |

| Chamber volume | 10.00~20.00 M3 |

Material

The filter plate of our chamber filter press is made of strengthenedpolypropylene that is imported from Finland, and is shaped through moldpressing. It is high in strength, light in weight, corrosion-resistant,non-poisonous and odorless.

The frame of our filter press is constructed by CO2 welding with carbon steelQ235B (C0.12~0.20% Mn0.30~0.670Si≤0.30S≤0.045P≤0.045). The surface is treatedby shot blasting and covered by epoxy coating or stainless steel 304.

Packaging

Our chamber filter press adopts the seaworthy package.

Zhongda Bright Company is a specialized 2000 chamberfilter press manufacturer based in China. We provide automatic chamberfilter press, PP membrane filter plate, membrane filter press, CGR filterplate, and others.

Links:https://www.globefindpro.com/products/93287.html

-

1200 PP Recessed Filter Plate

1200 PP Recessed Filter Plate

-

1500 Automatic Chamber Filter Press

1500 Automatic Chamber Filter Press

-

1600 Automatic Chamber Filter Press

1600 Automatic Chamber Filter Press

-

1250 Automatic Chamber Filter Press

1250 Automatic Chamber Filter Press

-

1000 Membrane Filter Press

1000 Membrane Filter Press

-

1500x2000 Membrane Filter Press

1500x2000 Membrane Filter Press

-

1600 Membrane Filter Press

1600 Membrane Filter Press

-

2 Color Flexo Printing Machine

2 Color Flexo Printing Machine

-

900 Chamber Filter Press

900 Chamber Filter Press

-

Food Paper Bag Making Machine

Food Paper Bag Making Machine

-

2000 Membrane Filter Press

2000 Membrane Filter Press

-

1000 Chamber Filter Press

1000 Chamber Filter Press