Auto Square Bottom Paper Bag Machine

Auto Square BottomPaper Bag Machine

Our auto square bottom paper bag machine can produce various paper bags with or without a handle. The handle formingsection makes handles using the twisted rope and paper patch. Then the handlesare conveyed to handle application section, which perforates the blank orprinted paper web, applies glue and pastes the handle to the web. With handles attached, the paperweb is fed into the main machine for side glue application, tube forming,cutting off, bottom forming, bottom glue application, bag forming and discharging. All these steps can be completed synchronously,which results in high efficiency of our auto square bottom paper bag machine. The whole machine is controlled by computer central control system withtouch screen and can produce bags in different sizes. The paper bag length iscontrolled by a servo motor.

Advantages

1. Our auto square bottompaper bag machine provides high speed. Within the suitablepaper range, it can achieve 120pcs/min, thus creating great value forcustomers.

2. The whole housing design ensures operator safety.

Technical Specifications of Auto Square BottomPaper Bag Machine

|

| Handle | Without Handle |

| Paper Width Range | 660-1310mm | 620-1310mm |

| Tube Length | 400-640mm | 400-760mm |

| Bag Body Width | 240-460mm | 220-460mm |

| Bag Bottom Width | 75-180mm | 75-180mm |

| Paper Weight | 115-150g/m2 | 90-150g/m2 |

| Max. Paper Roll Diameter | φ1500mm | φ1500mm |

| Material Core Diameter | 3″, 6″ | 3″, 6″ |

| Max. Mechanical Speed | 150pcs/min | 150pcs/min |

| Max. Production Speed | 120pcs/min | 120pcs/min |

| Total Power | 43kw | 43kw |

| Weight of Machine | About 16000kg | About 16000kg |

| Overall Dimension(LxWxH) | 14500mm×6000mm×2500mm | 14500mm×6000mm×2500mm |

美工注意:放附件3

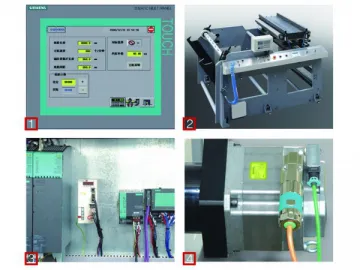

1. The touch screenhuman-machine interface allows easy correction and adjustment. In addition,alarms and working status can be displayed on the screen, which helpsfacilitate operation and maintenance.

2. New unwinding system: The paper roll diameter can be 1500mm, minimizing roll changefrequency. The use of automatic constant tension control system, Italian STautomatic web guiding control system and inverter motor for drawing rolleffectively reduces the adjustment time for paper roll alignment andpositioning, minimizes waste and increases efficiency.

3. Original German Siemens electric system contributes to better stability andreliability of our auto square bottom paper bag machine. The complete aftersale service translates into peace of mind for customers.

4. The paperbag machine is equipped with German Siemens servo motor andSICK photocell for correction, which ensures accurate tracking of the printedmaterial, thereby greatly reducing the adjustment, preset time and increasingthe production efficiency.

美工注意:放附件2

HandleLength(A): 120/135/150mm

Patch Width(B):50 mm

Patch Length(C): 200 mm

Handle Width(D): 100 mm

We are an auto square bottom paper bag machine supplierbased in China.We provide various types of products such as paper bag making machine, flexo printing machine, andnon-woven fabric making machine.

Links:https://www.globefindpro.com/products/93337.html

-

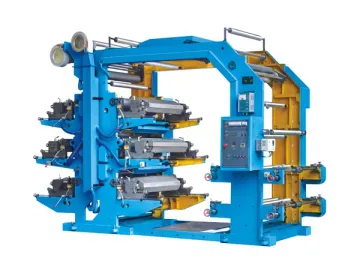

6 Color Flexo Printing Machine

6 Color Flexo Printing Machine

-

Ceiling PVC Film

Ceiling PVC Film

-

Non-woven Fabric Making Machine

Non-woven Fabric Making Machine

-

Automatic Non Woven Bag Making Machine

Automatic Non Woven Bag Making Machine

-

Paper Handbag Bottom Gluing Machine

Paper Handbag Bottom Gluing Machine

-

Translucent PVC Film

Translucent PVC Film

-

Adhesive Bandage PVC Film

Adhesive Bandage PVC Film

-

Ice Bag PVC Film

Ice Bag PVC Film

-

PVC Geomembrane

PVC Geomembrane

-

Custom Printed Paper Bag

Custom Printed Paper Bag

-

Diaper PVC Film

Diaper PVC Film

-

Paper Bag Making Machine

Paper Bag Making Machine