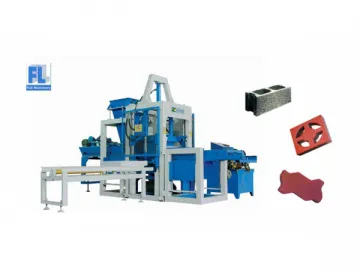

QT4-15 Automatic Block Making Machine

QT4-15 Automatic Block Making Machine

Technical Features of QT4-15 Automatic Block MakingMachine

1. Our automatic block making machine adopts imported PLC intelligent controlsystem. With human-machine interface and the control system with security logiccontroller, it has the functions of monitoring the production process, faultdiagnosis and treatment, and is updated with remote control system. In additionit does not required professionals, and it can be operated by common peoplewith short period of training.

2. Thehydraulic and sealing components of our automatic block making machine areimported ones, and proportional valves with high dynamic performance is applied.Thus, the oil level and pressure can be adjusted according to workingrequirements, to accurately control the operation of key components.

3. Thevibrator of our block making machine adopts synchronous vibration system withvariable frequency motors for vibration frequency control. Thus, the principleof feeding material with low frequency and molding products with high frequencyis available, to get fine vibration effect for different material and products.The vibration acceleration can be willfully adjusted as well.

4. The blockmolding machine is made of particular casting components of high accuracy andstrength with special welding technique, thus it has the characteristics ofhigh rigidity, vibration resistance and durability.

5. Theguidepost is made of particular steel with high strength, and is chrome plated,thus is highly twist and abrasion resistant

6. Thematerial distribution machine uses rotated equipment forcing the material to bedistributed, thus completely resolves the problem of distributing wet materialand the material for perforated brick making.

7. Our automatic block making machine adopts fourguideposts, accurately controls the operation of the press head and the mould.Products are molded with vibration on the vibration table and pressure. Thefeeding equipment is reciprocating oriented. As a result, our automatic blockmaking machine features fast and uniform material distribution, short moldingcycle, and high production efficiency. In addition, blocks obtained are of highintensity and strength in accurate size.

8. Ourautomatic block making machine can serve several purposes. By using differentmoulds, blocks of different sizes can be produced. It can also produce colorpavement brick if equipped with pigment device.

9. Ourautomatic block making machine adopts mechanism-electricity-hydraulicintegrated technology, to ensure the consistency of each running process of theequipment. As a result, blocks produced are of high stability and low rejectionratio.

Technical Specifications of our QT4-15 Automatic Block Making Machine

| Vibration frequency : 4000 to 5600 rolls/minute | Frequency range: 0 to 60Hz |

| Molding cycle time : 15-25s | Specification of molding box : 820*540mm |

| Motor power: 25.2KW | Gross weight: 5.5T |

| Pallet dimension : 880*535mm (Bamboo pallet) | Installation size : 12000 ×4000 ×3000mm |

| Output table ( L*W*H*mm ) | Hollow brick : 4 pcs / mould (390*190*190mm), 7500 pcs / day (8 hours) |

| Perforated brick : 14 pcs / mould (240*115*90mm), 24000 pcs / day (8 hours) | |

| Green brick: 14 pcs / mould (200*100*60mm), 20000 pcs / day (8 hours) | |

| Standard brick: 26 pcs / mould (238*115*51mm) , 45000 pcs / day (8 hours) | |

| Raw material | Macadam, sand, cement, dust, coal ash, slag, coal cinder, additives and industrial waste, etc. |

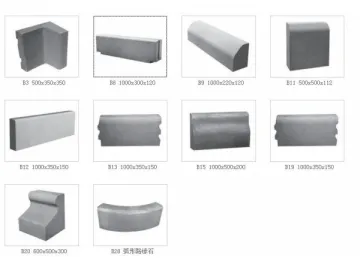

| Products | Color pavement brick (color in several single layers or the whole body), wharf chain brick, kerb stone, grass planting brick, hydraulic brick, hollow brick, perforated brick, burn-free standard brick, etc. |

| Note: 1. Brick of any size can be designed and produced as customers’ requirements. 2. Bricks produced can be widely used in the construction and paving of plaza, garden and city, as well as in water conservancy project. | |

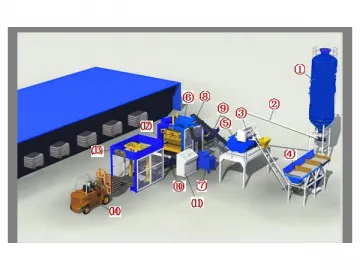

Simple Brick Production Line (10 to 12 workers needed)

1. Aggregate BatchingSystem

2.Mixing System

3. BeltConveyor

4.Automatic Brick Making Machine

5. Automatic Stacker

6. Control System

7.Forklift

8.CuringRoom

As a specialized automatic block making machine manufacturerand supplier in China, ourcompany also offers semi-automatic block making machine, mobile concrete mixingplant, fully automatic brick production line, and more.

Links:https://www.globefindpro.com/products/93386.html

-

QT10-15 Automatic Block Making Machine

QT10-15 Automatic Block Making Machine

-

QT3-20 Semi-automatic Block Making Machine

QT3-20 Semi-automatic Block Making Machine

-

QT8-15 Automatic Block Making Machine

QT8-15 Automatic Block Making Machine

-

Hydraulic Curbstone Making Machine

Hydraulic Curbstone Making Machine

-

Galvanized Steel Sheet Products

Galvanized Steel Sheet Products

-

Ready-mixed Concrete Mixing Plant

Ready-mixed Concrete Mixing Plant

-

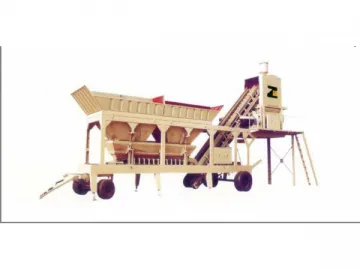

Mobile Concrete Mixing Plant

Mobile Concrete Mixing Plant

-

MATT Color Coated Steel Coil

MATT Color Coated Steel Coil

-

Hydraulic Brick Making Machine

Hydraulic Brick Making Machine

-

PPGI Steel Roof Tile

PPGI Steel Roof Tile

-

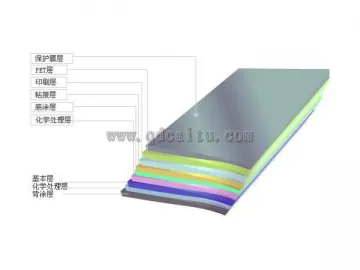

PET Steel Sheet

PET Steel Sheet

-

PPGI Sandwich Panel

PPGI Sandwich Panel