Color Coated Steel Coil

Color Coated Steel Coil

General Introduction on Color CoatedSteel Coil

Color coatedsteel coil refers to color coated steel sheet in coil. It is constructed usinggalvanized steel coil as the basic substrate material. After given surfacepretreatment such as degreasing, cleaning and chemical conversion, etc., thesubstrate material is then given coil coating by using roller coating method orcontinuous laminating. After baking and cooling of the coated substrate, colorcoated steel coil is achieved.

Color coated steel coil is also called prepainted galvanized steel coil.

Color coated steel coilfeatures aesthetical appearance and good corrosion resistance. It is an idealsteel material for use in construction, household appliance, ship building,automobile, furniture and electric industries.

As compared with similar materials like wood, color coated steel coil isenvironmental friendly and convenient for processing, and has lighter weight.It can be recycled, and little pollution is generated during its productionprocess. With light weight, it has low requirement on its bearing structure,thus saving construction cost. In addition, color coated steel coil is easy forprocessing. It can be processed into corrugated steel sheets in various shapesand lengths.

Detailed Introduction on ColorCoated Steel Coil

Why Color Coated Steel Coil?

1. Aesthetical architectural appearance

From 21st century,building materials such as color coated steel coil and corrugated steel sheetsare increasingly popular in construction industry. With good processingcapability, they allow for construction of buildings with beautiful curvedsurfaces and perfect combination of simplicity and lucidness, rigidness andflexibility. Color coated steel coil and related materials providesarchitects with broadened imagination and creation space.

2. Favorable self-cleaning performance

The surface of such colorcoated steel coil has a protective coating with a favorable thermo-insulatingproperty, through which, 70% of the solar heat can be reflected. Due to favorableself-cleaning performance of prepainted galvanized steel coils, 70% of thesurface glossiness is remained after 10 years’ direct sunshine.

3. Good flame and shock resistance

The color coated steel coilhas great flame retardanceand high temperature resistance, and thus it can satisfy the requirement forfire prevention. It also has a favorable shock resistance because of its lowdeadweight, high flexibility, and good deformability.

4. Short construction period

Color coated steel coils are easy for processing. They can be cut, bend, andcombined together conveniently. This makes them easy for installation andshorter construction period is required.

Detailed Applications of Color CoatedSteel Coil

Color coated steel coil can be processed into wall cladding material, metalroofing material, and various types of building decoration materials. Hence, ithas wide range of applications, and listed below are some of its typicalapplications.

1. Sports facilities

Color coated steel coil can be used in the construction and decoration ofvarious sports facilities such as stadium, natatorium, indoor tennis stadium,skating rink, and more.

2. Traffic facilities

Also, the precoated steel coils are ideal materialfor use in construction and decoration of toll station, gas station, parkinglots, pedestrian bridge, subway entrance, and more.

3. Cultural facilities

Color coated steel coils are also ideal wall cladding and roofing material for paradeground, meeting hall, club, exhibition center, and more.

4. Recreational facilities

Our precoated steel coil hasalso found applications in construction and decoration of recreationalfacilities such as park entrance, performance stage, music square, holidayvillage, and so on.

5. Commercial facilities

Color coated steel coil is also found in commercial pedestrian streets, shoppingmalls, and more.

6. Household appliances

With high surface quality and durability as well as economical benefits, colorcoated steel coil is a kind of increasingly popular housing material forrefrigerators, washing machines, air-conditioners and other domesticappliances.

7. Practical industrial facilities

In addition to above, our color coated steel coils, after processing, areextensively used in construction of workshop, dock, warehouse, among others.

Technical Specifications of ourColor Coated Steel Coil

Standard:We implement ISO9001:2000 quality management system standard while producingour color coated steel coil products. Our color coated steel coil is RoHS certified.

Thickness: Max. 1.0mm

Width: Max. 1500mm

Color: RAL color chart

Zinc coating: Max. 350g/sqm

Coating thickness:

25 microns/5-7microns (Polyester);

25 microns/25microns (Polyester)

35 microns/35microns (high weather resistant)

Others

Steel coil weight: Max. 12 tons

Production capacity: 250,000 tons/year

Links:https://www.globefindpro.com/products/93403.html

-

Concrete Pipe Making Machine

Concrete Pipe Making Machine

-

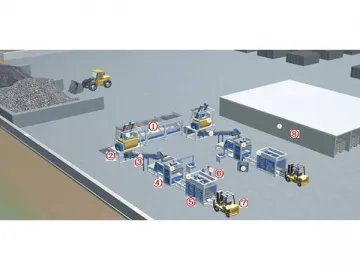

Semi-Automatic Brick Production Line

Semi-Automatic Brick Production Line

-

Simple Brick Production Line

Simple Brick Production Line

-

PPGI Printing Steel Sheet

PPGI Printing Steel Sheet

-

3.2KW 24V 9T CW Mitsubishi Starter, 2-2229-MI

3.2KW 24V 9T CW Mitsubishi Starter, 2-2229-MI

-

12V Armature IM2114

12V Armature IM2114

-

Fully Automatic Brick Production Line

Fully Automatic Brick Production Line

-

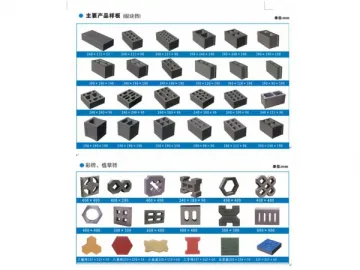

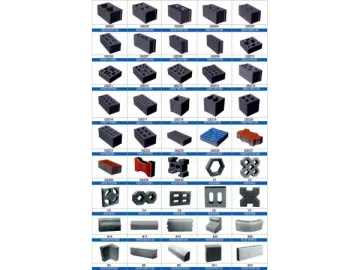

QT4-20 Semi-automatic Block Making Machine

QT4-20 Semi-automatic Block Making Machine

-

QT6-15 Automatic Block Making Machine

QT6-15 Automatic Block Making Machine

-

PPGI Drain Pipe

PPGI Drain Pipe

-

Home Appliance PPGI Steel Sheet

Home Appliance PPGI Steel Sheet

-

Modular Concrete Mixing Plant

Modular Concrete Mixing Plant