Semi-Automatic Brick Production Line

Semi-Automatic BrickProduction Line

Advantages of our Semi-Automatic BrickProduction Line (4 to 5 workers are needed)

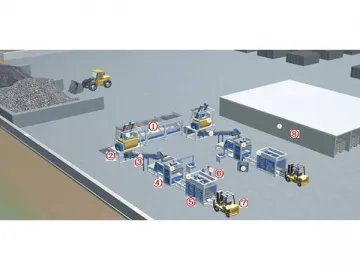

1.Our semi-automatic brick productionline is ideal for medium-sized brick making plants.

2. A floor area of 5000 m2 is needed.

3. Our semi-automatic brick production line is suitable for those transformingfrom a clay brick making plant to an enterprise or individual business with acertain amount of capital strength.

4. Mass production of building materials with a large production output can berealized by our production line, ensuring high annual profits.

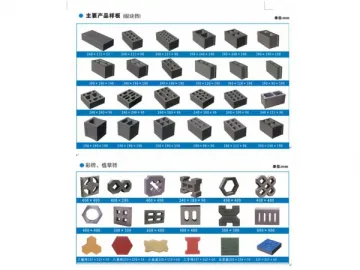

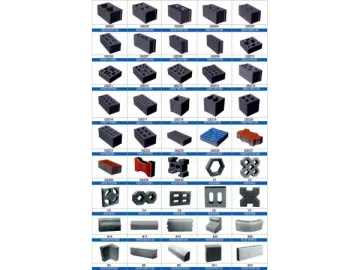

5. This semi automatic brick production line manufactures a variety of bricks,including standard bricks, perforated bricks, hollow bricks, color bricks,grass planting bricks, curbstones, and more.

6. The brick production line can be directed at construction projects ofperipheral countries and towns, and cities as well.

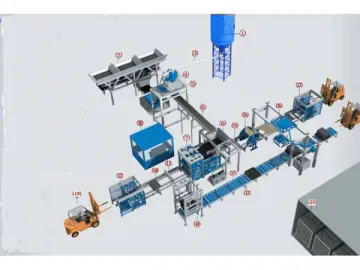

Construction of Semi-AutomaticBrick Production Line

1. Cement Silo 2. Batching Machine

3. Screw Conveyor 4. Cement Scale

5. Concrete Mixer 6. Belt Conveyor

7. Block Making Machine 8. Hopper

9. Pallets Feeder 10. Blocks Conveyor System

11. Clean Machine 12. Blocks Stacker

13. Skip Deliver System 14. Pallets Elevator and Lowerator

15. Pallets Tumbler 16. Cuber System

17. Hydraulic Unit 18. Control System

19. Forklift 20. Curing Room

Besides semi-automatic brick production line, we alsoprovide block making machine, concrete mixing plant, concrete pipe makingmachine, hydraulic brick machine and more.

Links:https://www.globefindpro.com/products/93405.html

-

Simple Brick Production Line

Simple Brick Production Line

-

PPGI Printing Steel Sheet

PPGI Printing Steel Sheet

-

3.2KW 24V 9T CW Mitsubishi Starter, 2-2229-MI

3.2KW 24V 9T CW Mitsubishi Starter, 2-2229-MI

-

12V Armature IM2114

12V Armature IM2114

-

7.2KW 24V 11T CW Delco Starter, 2-2345-DR (39MT)

7.2KW 24V 11T CW Delco Starter, 2-2345-DR (39MT)

-

12V 90A Hyundai Alternator, 37300-33103

12V 90A Hyundai Alternator, 37300-33103

-

Concrete Pipe Making Machine

Concrete Pipe Making Machine

-

Color Coated Steel Coil

Color Coated Steel Coil

-

Fully Automatic Brick Production Line

Fully Automatic Brick Production Line

-

QT4-20 Semi-automatic Block Making Machine

QT4-20 Semi-automatic Block Making Machine

-

QT6-15 Automatic Block Making Machine

QT6-15 Automatic Block Making Machine

-

PPGI Drain Pipe

PPGI Drain Pipe