Plate Heat Exchanger

Plate Heat Exchanger

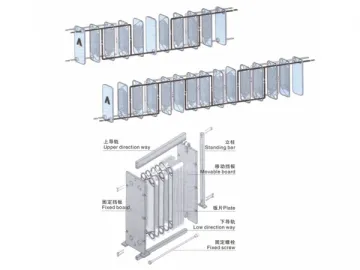

The plate heat exchanger givesexcellent heat transfer characteristics and is ideal where space islimited. Its plates areimported from Germany with CNC molding technology, high pressure and slow diestamping. Thus, deformation and scratches of the plate and the block enginecaused by unbalanced force are avoided, which leads up to a long service time.

The plate heat exchanger is made of 0.6-1.2 mmthick stainless steel SUS304, 304L321and 316L. It has properties of energy saving, quickly heattransfer, high efficiency of sterilization and balance of heat transferarea.

The plate heat exchanger has a flow channel designed todistribute heat on the surface of plate as evenly as possible, which makes fulluse of heat transfer area and guarantees high heat transfer efficiency. It canstand high working pressure, with contacts around the edge of plates to preventits deformation and the movement of the gaskets.

The plate heat exchanger is ideal for heating and cooling milk,fruit juice, dairy products and beverages. According to the needs of customers,the heat transfer area can be changed through adding or reducing the number ofplates.

Technical Data of PlateHeat Exchanger

| Model | Plate dimensions (mm) | Heat transfer area of single plate (m) | Angle hole diameter (mm) | Heat transfer area per set (m) | Max working pressure (MPa) | Max working temperature ( ℃ ) |

| BR 0.05 | 490×170×4.7 | 0.05 | φ34 | 0.5 -10 | 1.0 | -20 to 150 |

| BR 0.2 | 996×281×8.6 | 0.2 | φ65 | 1 -60 | 0.8 | -20 to 150 |

| BR 0.25 | 1160×330×5.6 | 0.25 | φ78 | 3 -60 | 0.5 | -20 to 150 |

| BR 0.32 | 1215×344×9.1 | 0.32 | φ82 | 3 -100 | 0.8 | -20 to 150 |

| BR 0.5 | 1364×466×5.8 | 0.5 | φ120 | 20 -134 | 0.8 | -20 to 150 |

| BR 0.6 | 1410×498×4.4 | 0.6 | φ150 | 15 -150 | 1.6 | -20 to 150 |

As a professional plate heat exchanger manufacturer andsupplier in China, Shanghai Yinji Machinery Co., Ltd also provides a tubular sterilizer, lab liquid sterilizing machine,high pressure homogenizer, aseptic bag filling machine and more.

Links:https://www.globefindpro.com/products/93855.html

-

Juice, Tea Drink Tubular Sterilizer

Juice, Tea Drink Tubular Sterilizer

-

Qseven Carrier Motherboard

Qseven Carrier Motherboard

-

4U Rackmount Industrial Computer

4U Rackmount Industrial Computer

-

Intel® GM45 Fanless Embedded Box PC

Intel® GM45 Fanless Embedded Box PC

-

Ultra Low Power PC/104 Embedded Motherboard

Ultra Low Power PC/104 Embedded Motherboard

-

X86 Embedded Multiple Network Transmission System

X86 Embedded Multiple Network Transmission System

-

Spray Tunnel Sterilizing Machine

Spray Tunnel Sterilizing Machine

-

Nature Juice Plate Sterilizer

Nature Juice Plate Sterilizer

-

Powder Dissolving Mixer

Powder Dissolving Mixer

-

UHT Milk Plate Sterilizer

UHT Milk Plate Sterilizer

-

Cap Sterilizing Machine

Cap Sterilizing Machine

-

Pasteurized Milk Plate Sterilizer

Pasteurized Milk Plate Sterilizer