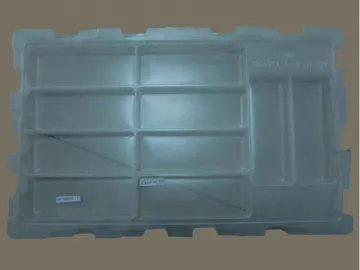

Plastic Luggage Vacuum Forming Cover

Plastic Luggage Vacuum Forming Cover

Theplastic luggage vacuum forming cover produced by our company is usually made ofABS material or PC material. By employing silkscreen technique, the cover haslined appearance in various colors of high luster type. As a professionalmanufacturer, our plastic luggage vacuum forming cover have high standard atreasonable price.

We customize plastic luggage vacuum formingcovers by using many types of ABS materials, whether generaltype or extrusion type, high luster type or matte type, common type orpatterned type, flame resistant type, heat resistant type or food grade type,and more.

ABS materials are available for both indoor and outdoor application (UVresistant). Keeping product performance and material cost in mind, we canalways choose the appropriate ABS materials to make plastic luggage covers. ABS vacuum forming has fast diesinking, with an average period of 6 to 25 days. In addition, the mold cost isrelatively low. PC vacuum forming productpresents high strength, flame-resistance and transparency. Thus it meets demandfor high strength. Only second to PMMA in transparency, it has manyapplications in lamp shades, lamp boxes, outdoor booths, buildings and more.

Vacuum forming technique is adopted for our plastic luggage covers,which is superior to injection molding and other techniques. Furthermore, thevacuum forming products are not restricted to size. Usually, the length can beover 10 meters, the width can reach 6 meters and the height can reach 1.2meters.

Links:https://www.globefindpro.com/products/94293.html