HDPE Vacuum Forming

HDPEVacuum Forming

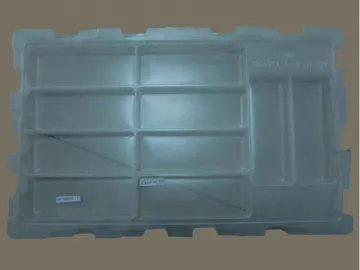

Made of HDPE material, HDPE vacuum forming product iswidely used in low-end commodities, casings and non load-bearing carriers liketurnover trays, boxes, containers, extrusion packaging film, ropes, woven bags,fishing nets, air-condition pipelines, water pipes, and more. However, due to great molding difficulty and high contraction rate, HDPEvacuum forming product is not suitable for complex-structured products withhigh fitting requirements. Listed below are advantages and disadvantages ofHDPE vacuum forming products, thus clients can decide whether to use HDPE asthe raw material for their vacuum forming products.

Advantages ofour HDPE Vacuum Forming

1. Our HDPE vacuum formingproduct is low in cost.

2. Thisproduct is resistant to impact, abrasion, acids, alkalis, organic solvent andlow temperature.

3. Itfeatures excellent electric insulating property.

4. Our HDPEvacuum forming product is superior to that of LDPE and approximate to that ofPP in case hardness, tensile strength and rigidity, and tougher than that ofPP.

Disadvantages of our HDPE Vacuum Forming

1. HDPE vacuum forming producthas poor mechanical property and air permeability.

2. Thisproduct is prone to deformation, aging, crack and scratch.

3. It haslow case hardness, and is superior to that of PP in brittleness and surfacefinish.

4. Our HDPEvacuum forming is difficult to print, its material needs electro dischargetreatment in surface.

5. HDPEvacuum forming product is lackluster in appearance and can not be plated.

The HDPE vacuum forming products are not restricted to size. Typically, thelength can be over 10 meters, the width can reach 6 meters and the height canreach 1.2 meters. The die sinking period is usually from 6 to 25 days, and thebulk production can be accomplished within 12 to 25 days.

Links:https://www.globefindpro.com/products/94294.html