HIPS Vacuum Forming

HIPS Vacuum Forming

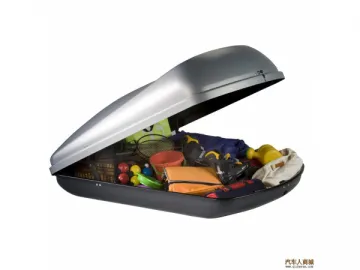

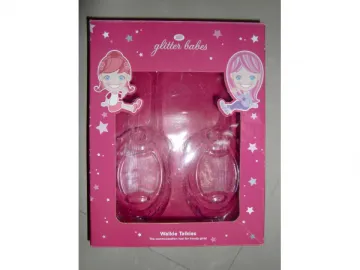

HIPS vacuum forming product ismade of HIPSmaterial and it features opaque appearance. We can offer HIPS vacuuming formingproduct widely used in displays, advertising industry, and more.

Features of HIPSVacuum Forming Product

1. HIPS vacuum forming product is cheaper than ABSmaterial and the HIPS material is inferior to ABS in strength and luster. HIPSis a modified material of PS and has 5% to 15% of rubber. Besides, the HIPSproduct features high dyeability.

2. HIPS vacuum forming product enjoys high toughness,four times more than that of PS and a higher strength. HIPS material has low water-absorptioncapability and needs not to be pre-dried before processing. The low moleculemobility within HIPS requires relatively high injection pressure and moldtemperature (AVG. 190-240℃).

3. With a slower cooling rate than PS, HIPS requires sufficient packingpressure, packing time and cooling time. Moreover, HIPS has a longer moldingperiod than PS.

4. The problem of “white edge” in the HIPS vacuuming products can be solved byincreasing mold temperature and mold damping force as well as decreasing thepacking pressure and time.

5. The HIPS vacuum forming products are not restricted to sizes. Typically, thelength can be over 10 meters, the width can reach 6 meters and the height canreach 1.2 meters. The die sinking period is usually from 6 to 25 days, and thebulk production is accomplished within 12 to 25 days.

Links:https://www.globefindpro.com/products/94297.html