Medical Vacuum Forming Cover

Medical Vacuum Forming Cover

Our company manufactures medical vacuum forming covers byemploying techniques of vacuuming forming, splicing, CNC processing, burnishingand more. The medical vacuum forming cover is usually made of ABS material.

To accommodate different applications and requirements of our customers, we can make medicalvacuum forming cover using many types of ABS materials, whether generaltype or extrusion type, high shock-resistant type or common type, high luster type or matte type, common type or patterned type,flame resistant type, heat resistant type or food grade type, and more. ABS materials are also used for both indoor andoutdoor application (UV resistant). Keeping product performance and materialcost in mind, we can always choose the appropriate ABS materials to make medical vacuum forming cover.

Our medical vacuum formingcover adopts vacuum forming technique, featuring many advantages overinjection molding and other techniques. ABS vacuum forming presents fast diesinking, with an average period of 6 to 25 days. Additionally, the mold cost isrelatively low and the products are not restricted to size. Usually, the lengthcan be over 10 meters, the width can reach 6 meters and the height can reach1.2 meters.

Links:https://www.globefindpro.com/products/94321.html

-

Desktop CNC Plasma Cutting Machine

Desktop CNC Plasma Cutting Machine

-

Cosmetics Blister Pack

Cosmetics Blister Pack

-

Double Deck Vacuum Forming Cover

Double Deck Vacuum Forming Cover

-

Industry Vacuum Forming Cover

Industry Vacuum Forming Cover

-

PMMA/ABS Vacuum Forming

PMMA/ABS Vacuum Forming

-

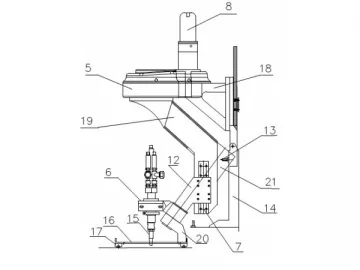

CNC Flame Bevel Cutting Machine

CNC Flame Bevel Cutting Machine

-

Precision CNC Plasma Cutting Machine

Precision CNC Plasma Cutting Machine

-

Kjellberg Plasma Power

Kjellberg Plasma Power

-

Fastcam Nesting Software

Fastcam Nesting Software

-

Robot Flame Bevel Cutting Machine

Robot Flame Bevel Cutting Machine

-

Combined Plasma Cutting Machine

Combined Plasma Cutting Machine

-

Multi Head CNC Flame Cutting Machine

Multi Head CNC Flame Cutting Machine