PMMA/ABS Vacuum Forming

PMMA/ABS Vacuum Forming

Made of PMMA/ABS composite material, PMMA/ABS vacuum forming product has advantages of bothPMMA and ABS materials and and is widely used intop-grade and bright-colored electrical appliances, electronic components andother fitting parts, especially white goods like LCD, TV. The product has highluster and is free of coating.

Features of PMMA/ABS Vacuum Forming Product

1. PMMA/ABS vacuum forming product is UV resistant, and has highstrength, high brightness and fashionable appearance.

2. Theproduct is easy to process since the composite material enjoys good processability and toughness that are typical of ABSmaterial.

3. OurPMMA/ABS vacuum forming product features excellent weather fastness,scrape-resistance, case hardness and luster attributable to PMMA material.

The maximumproduct performance of PMMA/ABS composite material is primarily made up of ABSmaterial and slightly of PMMA. The thickness of PMMA used is around 0.06mm to 0.1mm.Single-layer composite material like PMMA/ABS and double-layer compositematerial like PMMA/ABS/PMMA are available.

Our PMMA vacuum forming and ABSvacuum forming product are not restricted to size. In general, the lengthcan be over 10 meters, the width can reach 6 meters and the height can reach1.2 meters. The die sinking period is usually from 6 to 25 days, and the bulkproduction is accomplished from 12 to 25 days.

Links:https://www.globefindpro.com/products/94329.html

-

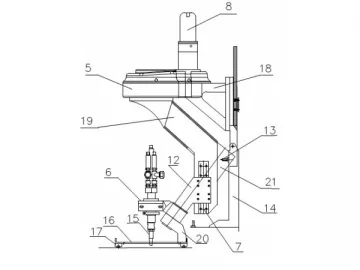

CNC Flame Bevel Cutting Machine

CNC Flame Bevel Cutting Machine

-

Vacuum Forming Car Cover

Vacuum Forming Car Cover

-

Hypertherm Fine Plasma Power

Hypertherm Fine Plasma Power

-

EDGE Pro Control System

EDGE Pro Control System

-

Advertising Light Clamshell Cover

Advertising Light Clamshell Cover

-

Vacuum Forming Storage Tray

Vacuum Forming Storage Tray

-

Industry Vacuum Forming Cover

Industry Vacuum Forming Cover

-

Double Deck Vacuum Forming Cover

Double Deck Vacuum Forming Cover

-

Cosmetics Blister Pack

Cosmetics Blister Pack

-

Desktop CNC Plasma Cutting Machine

Desktop CNC Plasma Cutting Machine

-

Medical Vacuum Forming Cover

Medical Vacuum Forming Cover

-

Precision CNC Plasma Cutting Machine

Precision CNC Plasma Cutting Machine