Hypertherm Fine Plasma Power

Hypertherm Fine Plasma Power

Our company supplies a range of Hypertherm plasma power products including Powermax series(Powermax1250/Powermax1650), MAX200, long-life HSD130/HT200 in addition to Hypertherm fine plasma power HPRXD series.

Advantages of Hypertherm Fine Plasma Power

1. HyDefinition technology

a. Vented nozzle technology aligns and focusesthe plasma arc.

b. HyDefinition technology enables powerful precisioncutting for superior quality and consistency.

2. LongLife technology

a. Ramps electricalcurrent and gas pressure up and down in a tightly controlled manner.

b. Toreduce electrode and nozzle erosion, LongLife technology delivers consistent HyDefinition cutquality over the longest period of time for a significant reduction in operatingcost and downtime.

3. PowerPierce technology

a. Liquid cooled shield technology repels molten metal duringpiercing.

b. PowerPierce technology enables robust production piercing capability up to 50 mm (2")mild steel.

c. Patented consumable designs deliver speed and thicknesscapabilities expected of higher amp systems.

4. TrueHole™ technology

StandardSpecifications of HPR130XD Plasma Power

| Model | HPR130XD | ||

| Virtually dross free | Mild Steel 16mm |

|

|

| Production (piercing) | Mild Steel 32mm | Stainless Steel 20mm | Aluminum 20mm |

| Severance (edge starts) | Mild Steel 38mm | Stainless Steel 25mm | Aluminum 25mm |

| Process gases by material | O2/Air, O2/O2, Ar/Air | H35/N2, N2/N2, H35-N2/N2, F5/N2, Ar/Air, Ar/N2 | H35/N2, Air/Air, H35-N2/N2, N2/Air, Ar/Air, Ar/N2 |

| Process amps (Cutting) | 30-130A | ||

StandardSpecifications of HPR260XD Plasma Power

| Model | HPR260XD | ||

| Virtually dross free | Mild Steel 32mm |

|

|

| Production (piercing) | Mild Steel 38mm | Stainless Steel 32mm | Aluminum 25mm |

| Severance (edge starts) | Mild Steel 64mm | Stainless Steel 50mm | Aluminum 50mm |

| Process gases by material | O2/Air, O2/O2, Ar/Air | H35/N2, N2/N2, H35-N2/N2, F5/N2, Ar/Air, Ar/N2 | H35/N2, Air/Air, H35-N2/N2, N2/Air, Ar/Air, Ar/N2 |

| Process amps (Cutting) | 30-260A | ||

StandardSpecifications of HPR400XD Plasma Power

| Model | HPR400XD | ||

| Virtually dross free | Mild Steel 38mm |

|

|

| Production (piercing) | Mild Steel 50mm | Stainless Steel 45mm | Aluminum 45mm |

| Severance (edge starts) | Mild Steel 80mm | Stainless Steel 80mm | Aluminum 80mm |

| Process gases by material | O2/Air, O2/O2, Ar/Air | H35/N2, N2/N2, H35-N2/N2, F5/N2, Ar/Air, Ar/N2 | H35/N2, Air/Air, H35-N2/N2, N2/Air, Ar/Air, Ar/N2 |

| Process amps (Cutting) | 30-400A | ||

StandardSpecifications of HPR800XD Plasma Power

| Model | HPR800XD | ||

| Virtually dross free | Mild Steel 38mm |

|

|

| Production (piercing) | Mild Steel 50mm | Stainless Steel 75mm | Aluminum 75mm |

| Severance (edge starts) | Mild Steel 80mm | Stainless Steel 160mm | Aluminum 160mm |

| Process gases by material | O2/Air, O2/O2, Ar/Air | H35/N2, N2/N2, H35-N2/N2, F5/N2, Ar/Air, Ar/N2

| H35/N2, Air/Air, H35-N2/N2, N2/Air, Ar/Air, Ar/N2 |

| Process amps (Cutting) | 30-800A | ||

Links:https://www.globefindpro.com/products/94332.html

-

EDGE Pro Control System

EDGE Pro Control System

-

Advertising Light Clamshell Cover

Advertising Light Clamshell Cover

-

Vacuum Forming Storage Tray

Vacuum Forming Storage Tray

-

DIN 1329 PVC Pipe and Fitting

DIN 1329 PVC Pipe and Fitting

-

Italian PP Compression Fitting

Italian PP Compression Fitting

-

Brass Fitting

Brass Fitting

-

Vacuum Forming Car Cover

Vacuum Forming Car Cover

-

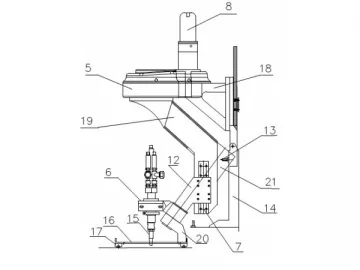

CNC Flame Bevel Cutting Machine

CNC Flame Bevel Cutting Machine

-

PMMA/ABS Vacuum Forming

PMMA/ABS Vacuum Forming

-

Industry Vacuum Forming Cover

Industry Vacuum Forming Cover

-

Double Deck Vacuum Forming Cover

Double Deck Vacuum Forming Cover

-

Cosmetics Blister Pack

Cosmetics Blister Pack