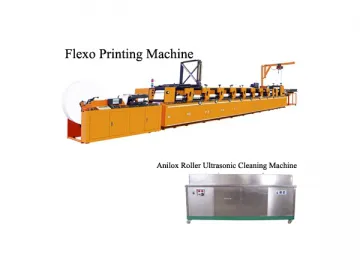

Flexo Printing Machine

Structural Features

1. This flexo priting machine integrates benefits of relief printing, planographic printing, and intaglio printing. It comes with clear printing, light printing force, and durable printing plate. It carries out fine printing on absorptive or non-absorptive papers, thick or thin papers, and papers with smooth surface or rough surface.

2. This printing machine is of unit construction, which avoids the shortcomings of Satellite type and Compact type printing machines. It is of precise registration, fine printing effect, high productivity and efficiency. It could be used for homochromatic or polychromatic printing on single side or double sides of the paper.

3. Each unit of this printing machine has integral steel frame-board that are 65mm thick. They ensure the good stability of the machine during high speed running.

4. This flexo printing machine has advanced tension control system and web guide system for the coiled materials. The tension control system adopts closed loop tension control. The unwinder and rewinder adopt inverter of tension control and tension sensor conversion equipment to make sure the electro motor offer stable tension . The web guiding system adopts German E L electrical web guiding system and synchronous belt drive.

5. It is equipped with British Static Dirt-proof system and CE-certified corona treatment system.

6. The anilox roller device of this flexo printing machine is of drawer design. With slide-rail, it is pneumatically controlled for easier, faster, and safer loading and unloading. The high precision mechanical machining ensures the anilox roller to keep a stable pressure for stable printing effect.

7. Its main driving shaft comes with a diameter of 40 mm, which ensures non-distortion power transmission.

8. It adopts high-efficiency warm air , infrared or UV drying system.

9. It has a synchronous stroboscopes still image inspection system to ensure accurate registration.

10. The electro-hydraulic control system converts the high voltage into 24V low voltage. Each PLC controls two printing units, making it safer and easier to operate this printing machine.

11. This machine could be equipped with optional cross cutting, slitting, edge rewinding, vacuum waste discharging, die-cutting, code spraying, adhesive material peeling, printing and recombining, screen printing, stamping, and laminating units.

12. We have developed non-shaft automatic registration system and independent drying system for each printing unit. These systems greatly improve the energy efficiency and reduce the emission and the costs. The non-shaft transmission system adopts no shaft drive . Instead, it controls each printing units separately through PLC system and servo motor.

Technical Specification

| Specification | Narrow type | Medium type | |||||

| 10 "(254) | 13"(330) | 16.5"(420) | 20.5 "(520) | 25.5 "(650) | 32.5" (830) | 35.5" (900) | |

| Max. Web Width(mm) | 260 | 340 | 430 | 530 | 660 | 850 | 920 |

| Max. Printing Width(mm) | 254 | 330 | 420 | 520 | 650 | 830 | 900 |

| Max. Die-cutting Width(mm) | 254 | 330 | 420 | 520 | 650 | 830 | 900 |

| Printing Repeat(mm)(mm) | 180-435 | 190-650 | 190-650 | 190-650 | 190-650 | 286-1200 | 286-1200 |

| Die-cutting Repeat(mm) | 180-435 | 190-650 | 190-650 | 190-650 | 190-650 | 286-1200 | 286-1200 |

| Max. Unwinder Diameter(mm) | 500 | 1067 | 1524/1067 | 1524/1067 | 1524/1067 | 1524/1200 | 1524/1200 |

| Max. Rewinder Diameter(mm) | 500 | 1067/762 | 1067/762 | 1067/762 | 1067/762 | 1524/1200 | 1524/1200 |

| Gearing(cp) | 1/8 | 1/8 | 1/8 | 1/8 | 1/8 | 1/8 | 1/8 |

| Max. Printing Speed(m/min) | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Diameter of Web Roller(mm) | 60 | 75 | 75 | 75 | 75 | 100 | 100 |

| Base Motor Power(KW) | 7.5 | 11 | 11 | 11 | 11 | 15 | 15-22 |

| Specification | Medium type | Wide type | ||||

| 39.5" (1000) | 43.3" (1100) | 47.5" (1200) | 50.4" (1280) | 56.5" (1430) | 64.2" (1630) | |

| Max. Web Width(mm) | 1020 | 1120 | 1220 | 1300 | 1450 | 1650 |

| Max. Printing Width(mm) | 1000 | 1100 | 1200 | 1280 | 1430 | 1630 |

| Max. Die-cutting Width(mm) | 1000 | 1100 | 1200 | 1280 | 1430 | 1630 |

| Printing Repeat(mm) | 286-1200 | 286-1200 | 286-1200 | 600-1430 | 600-1430 | 600-1430 |

| Die-cutting Repeat(mm) | 286-1200 | 286-1200 | 286-1200 | |||

| Max. Unwinder Diameter(mm) | 1524/1200 | 1524/1200 | 1524/1200 | 1524 | 1524 | 1524 |

| Max. Rewinder Diameter(mm) | 1524/1200 | 1524/1200 | 1524/1200 | 1524 | 1524 | 1524 |

| Gearing(cp) | 1/8 | 1/8 | 1/8 | 1/8 | 1/8 | 1/8 |

| Max. Printing Speed(m/min) | 150 | 150 | 150 | 150 | 150 | 150 |

| Diameter of Web Roller(mm) | 100 | 100 | 100 | 100 | 100 | 100 |

| Base Motor Power(KW)) | 15-22 | 15-22 | 15-22 | 22-30 | 22-30 | 22-30 |

Applications

1. This machine adopts non-toxic water-based ink or UV ink, which are environmental friendly and suitable for printing applications in food and beverage packaging, pharmaceutical packaging, cartons preprinting, hang tag, labeling, and more industries.

2. The narrow type of this flexo printing machine with a printing width ranging from 10 inches to 25.5 inches (254mm-650mm) is suitable for printing on various aluminum foils, non-stretching plastic films, pressure-sensitive adhesives, coated paper, 17g copy paper, tissue paper, kraft paper, BOPP, PET and more composite materials.

3. The medium type flexo printing machine with a printing width ranging from 32.5 inches to 47.5 inches (830mm-1200mm) is suitable for printing on web used for the production of paper cups, paper bowls, paper buckets, paper cartons, paper bags, etc.

4. The wide type with a printing width ranging from 50.4 inches to 64.2 inches (1280mm-1630mm) is suitable for printing on web used for the production of cartons.

This flexo printing machine can be available with 1 to 12 printing colors.

Links:https://www.globefindpro.com/products/94582.html

-

Paper Bowl Forming Machine

Paper Bowl Forming Machine

-

High-speed Medical Paper/Plastic Bag Making Machine

High-speed Medical Paper/Plastic Bag Making Machine

-

High-Speed Paper and Plastic Coating Machine

High-Speed Paper and Plastic Coating Machine

-

Automatic Non Woven Bag Making Machine

Automatic Non Woven Bag Making Machine

-

High Speed Double PE Coated Paper Cup Forming Machine

High Speed Double PE Coated Paper Cup Forming Machine

-

Automatic Small Packing Machine

Automatic Small Packing Machine

-

Automatic Paper Cake Tray Forming Machine

Automatic Paper Cake Tray Forming Machine

-

Creasing and Cutting Machine

Creasing and Cutting Machine

-

Mini Folding Machine

Mini Folding Machine

-

Semi-Automatic Paper Pasting Machine

Semi-Automatic Paper Pasting Machine

-

Automatic Food Paper Bag Making Machine

Automatic Food Paper Bag Making Machine

-

Compact Flexo Printing Machine

Compact Flexo Printing Machine