Automatic Small Packing Machine

WLAS-201 Automatic Small Packing Machine

Features

1. The automatic small packing machine features Mitsubishi programmed controller (PLC) and large touch screen which are centrally controlled by the servo electrical machinery.

2. It mixes the malfunction auto-tracking system with the warning system, which displays real-time data through the touch screen, finds out the fault cause and fault location rapidly, and deals with failure in time.

3. This automatic small packing machine uses high-accuracy Omron photoelectrical tracking device.

4. It adopts the circulating lubrication system to automatically deliver lubricants to the required points so as to extend the service life of its components greatly.

5. It takes use of imported antistatic device which enhances the stability of packing performance. Moreover, this automatic small packing machine adopts imported intelligent temperature-control system, which voluntarily controls the temperature.

Finished Product Package Size

Standard handkerchief 103-105(Lengthen)×53±1(Width)×26mm(Height) (10sheets,3 ply)

Mini-handkerchief 73-75( Length) ×53±1(Width)×26mm(Height) (10sheets,3 ply)

Packing Material Size

Packing material: PE or CPP film roll, thickness: 0.04-0.05mm

Film Roll Width: for Standard handkerchief: 146-150mm

for Mini handkerchief:115-120mm

Max. Dia.: of film roll: 400mm

Core inner dia.: Of film roll:3"

Control

PLC control

Speed adjusting by inverter

Touch screen operation panel

Intelligent temperature controller

Breakdown warning device

Special static removing unit

This automatic small packing machine employs automatic greasing system, which can prolong the life of machine.

Labeling and Perforating on Packing Film

Automatic

Capacity

60-70 packs/min

Links:https://www.globefindpro.com/products/94589.html

-

Pneumatic Hydraulic Cardboard Laminating Machine

Pneumatic Hydraulic Cardboard Laminating Machine

-

Automatic Cup Lid Forming Machine

Automatic Cup Lid Forming Machine

-

Paper Cups

Paper Cups

-

EGT98 Long Haul Truck Tire

EGT98 Long Haul Truck Tire

-

EA828 Truck Tire, Bus Tire

EA828 Truck Tire, Bus Tire

-

EGT58 Truck Tire, Bus Tire

EGT58 Truck Tire, Bus Tire

-

High Speed Double PE Coated Paper Cup Forming Machine

High Speed Double PE Coated Paper Cup Forming Machine

-

Automatic Non Woven Bag Making Machine

Automatic Non Woven Bag Making Machine

-

High-Speed Paper and Plastic Coating Machine

High-Speed Paper and Plastic Coating Machine

-

High-speed Medical Paper/Plastic Bag Making Machine

High-speed Medical Paper/Plastic Bag Making Machine

-

Paper Bowl Forming Machine

Paper Bowl Forming Machine

-

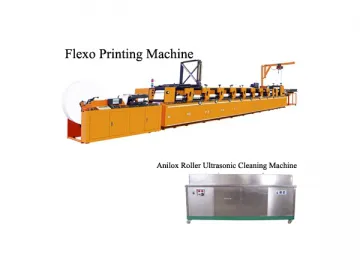

Flexo Printing Machine

Flexo Printing Machine