Plastic Granulator

WLZL100/100 PE PP Plastic Granulator

Features

1. This plastic granulator can be used to recycle the PP, PE plastic wastes and process these wastes back into raw materials so as to improve the availability of raw materials greatly and reduce the cost.

2. The key part of this plastic granulator is made by stainless steel, whcih ensure its long service life.

3. The electrical parts are imported products of international famous brands , which guarantees the high quality of our plastic granulator.

4. This plastic granulator has the CE and ISO certificates.

Techinal Specification

1.Screw Feeder

(1) Motor Power: 2.2kw

(2) Frequency conversion control

(3) Diameter: 250mm

(4) Effective Length: 3000mm

(5)The screw feeder of this plastic granulator is made by stainless steel SUS304

2. Forced Feeder

(1) Motor power: 3kw

(2) Frequency conversion control

3. Single Screw Extruder (Mainframe of this plastic granulator)

(1) Reduction Gearbox Type 225: high torque, low noise, hard tooth flank gear grinding, connect externally with recirculating cooling system

(2) Material of Screw: 38 CrMoAlA, nitriding

(3) Material of Stuff Canister: 38 CrMoAlA, nitriding

(4) Screw Diameter: 100mm

(5) Length-to-Diameter Ratio: 25:1

(6) Motor Power: 45kw

(7) Heating Zone: the 8th zone

(8) Constant Temperature zone: the 5th zone

(9) Hydraulic screen changer

4. One-Stage extuder (auxiliary equipment of this plastic granulator)

(1) Reduction Gearbox Type 225: high torque, low noise, hard tooth flank gear grinding, connect externally with recirculating cooling system

(2) Material of Screw: 38 CrMoAlA, nitriding

(3) Material of Stuff Canister: 38 CrMoAlA, nitriding

(4) Screw Diameter: 100mm

(5) Length-to-Diameter Ratio:10:1

(6) Motor Power: 22kw, frequency conversion control

(7) Heating Zone: the 6th zone

(8) Constant Temperature zone: the 3rd zone

(9) Hydraulic screen changer

5. Cooling Tank

(1) Length: 4m

(2) The control tank of this plastic granulator is made by stainless steel

(3) A set of water tank shlef

6. Air Blower

(1) Motor Power: 2.2kw

(2) The major parts of this plastic granulator are made by stainless steel.

7. Granulator

(1) Motor Power: 3kw

(2) Frequency conversion control

8. Blowing System

Motor Power: 2.2kw

9. Storage Hopper

(1) Volume: 500kg

(2) The storage hopper of this plastic granulator is made by stainless steel SUS 304

10. Electrical control system

(1) Temperature Controll meter: Omron, Japan

(2) Contactor: Delixi

(3) Frequency Converter: TECO, Japan

11. Production

Film Materials: 80~120kg/h

Hard Materials:100~150kg/h

Links:https://www.globefindpro.com/products/94603.html

-

Double-head Film Blowing Machine Set

Double-head Film Blowing Machine Set

-

Automatic T Shirt Bag Making Machine

Automatic T Shirt Bag Making Machine

-

Grass Silage Film

Grass Silage Film

-

EG902 Long Haul Truck Tire

EG902 Long Haul Truck Tire

-

EGT68 Bus Tire, Truck Tire

EGT68 Bus Tire, Truck Tire

-

PE Stretch Film

PE Stretch Film

-

EGT88 Long Haul Truck Tire

EGT88 Long Haul Truck Tire

-

EA822 Long Haul Truck Tire

EA822 Long Haul Truck Tire

-

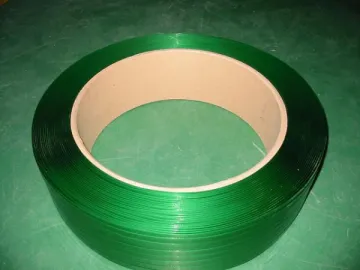

PET Strapping Band

PET Strapping Band

-

EG801 Long Haul Truck Tire

EG801 Long Haul Truck Tire

-

EGT97 Bus Tire, Truck Tire

EGT97 Bus Tire, Truck Tire

-

PE Shrink Film

PE Shrink Film