Double-head Film Blowing Machine Set

Double-head Film Blowing Machine Set

Characteristics

1. Both the cylinder and the screw of the extruder are made of high quality alloy steel through nitration and precision finishing with the best hardness and corrosion resistance.

2. Scientifically designed, this double-head film blowing machine has two heads for one extruder with such advantages as increasing production capacity, saving energy, labor and workshop area, etc.

Application

This double-head film blowing machine is used for blowing low-density polyethylene (LDPE) and high-density polyethylene (HDPE) plastic film to make various vest bags and flat-rim bags which have been widely used for packing in the food, garment and textile industries, etc.

Technical parameters

| Model | CM-65FM-600 | CM-70FM-700 | CM-75FM-800 |

| Screw Diameter | 65mm | 70mm | 75mm |

| Screw Ratio | 1:28 | 1:28 | 1:28 |

| Screw Speed | 10-110r/min | 10-110r/min | 10-110r/min |

| Max. Output | 50kg/h | 70kg/h | 90kg/h |

| Max. Folding Width of Film | 550mm×2 | 650mm×2 | 750mm×2 |

| Single-Sided Thickness of Film | 0.006-0.10mm | 0.006-0.10mm | 0.006-0.10mm |

| Power of Main Motor | 18.5-22Kw | 22-30Kw | 37Kw |

| Total Power | 40Kw | 55Kw | 70Kw |

| Overall Dimension | 4800×2200×3800 | 5000×2400×4000 | 5200×2600×420 |

Scan QR to Read

Links:https://www.globefindpro.com/products/94604.html

Links:https://www.globefindpro.com/products/94604.html

Recommended Products

-

Automatic T Shirt Bag Making Machine

Automatic T Shirt Bag Making Machine

-

Grass Silage Film

Grass Silage Film

-

EG902 Long Haul Truck Tire

EG902 Long Haul Truck Tire

-

EGT68 Bus Tire, Truck Tire

EGT68 Bus Tire, Truck Tire

-

PE Stretch Film

PE Stretch Film

-

Film Blowing and Printing Machine

Film Blowing and Printing Machine

-

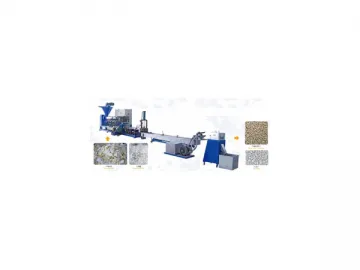

Plastic Granulator

Plastic Granulator

-

EGT88 Long Haul Truck Tire

EGT88 Long Haul Truck Tire

-

EA822 Long Haul Truck Tire

EA822 Long Haul Truck Tire

-

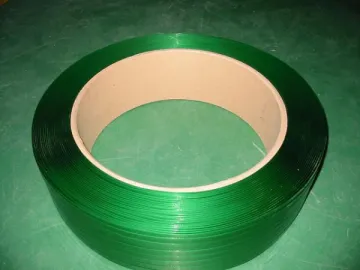

PET Strapping Band

PET Strapping Band

-

EG801 Long Haul Truck Tire

EG801 Long Haul Truck Tire

-

EGT97 Bus Tire, Truck Tire

EGT97 Bus Tire, Truck Tire

Hot Products