Catalytic Converter Mesh Wrap

Catalytic Converter Mesh Wrap

The mesh wrap hasbeen designed to protect the fragile ceramic honeycomb brick within a catalyticconverter from vibration and shock damage. Normally constructed from crimpedknitted wire mesh, often in conjunction with an integral strip of intumescent mat material,catalytic converter mesh wrap is usually joined to create a one-piece componentthat is easily fitted over the ceramic brick during the canning process. Thetiny springs that are created during mesh knitting cushion the ceramic brick,preventing damage from the most severe vibration a catalytic converter mightexperience.

Range of Materials

The catalytic converter mesh wrapis normally manufactured from grade 304, 316, 321, 310 and 310S stainlesssteel. High nickel content alloys such as Inconel* 601 are used forhigh temperature applications, especially when the converter unit is positionedclose to the engine manifold.

Features and Benefits

1. The catalytic converter mesh wrap provides good protectionfrom shock and vibration.

2. It is an easily-fit component for highly cost-effective mass production.

3. Totally recyclable material

4. The mesh wrap withstands high temperatures andcorrosive exhaust gas.

5. The catalytic converter mesh wrap fits any shape or size of ceramic brick.

6. It is available in a range of materials, from 304 gradestainless steel for low temperature applications to higher nickel alloyscapable of withstanding temperatures in excess of 1000°C.

As a professional catalyticconverter mesh wrap manufacturer based in China, Yanda-Guohai provides a wide array of products that includes an airbag filter knitted wiremesh, submerged arc welding wire, TIG stainless steel welding wire, and more.

Links:https://www.globefindpro.com/products/94817.html

-

Filtration Wire Mesh

Filtration Wire Mesh

-

ER308 ER308L ER308LSi TIG Welding Wire

ER308 ER308L ER308LSi TIG Welding Wire

-

EMI Wire Mesh Shielding Tape

EMI Wire Mesh Shielding Tape

-

Wire Mesh Resilient Core, Gasket

Wire Mesh Resilient Core, Gasket

-

ER309 ER309L ER309LSi MIG Welding Wire

ER309 ER309L ER309LSi MIG Welding Wire

-

Anti-Vandal Knitted Wire Mesh

Anti-Vandal Knitted Wire Mesh

-

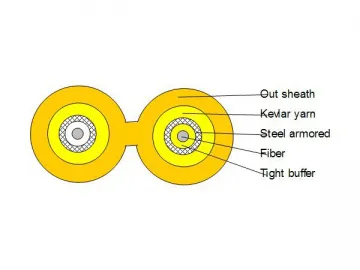

Duplex Fiber Armored Fiber Optic Cable

Duplex Fiber Armored Fiber Optic Cable

-

ADSS Fiber Optic Cable

ADSS Fiber Optic Cable

-

2 Port Vertical Fiber Optic Enclosure

2 Port Vertical Fiber Optic Enclosure

-

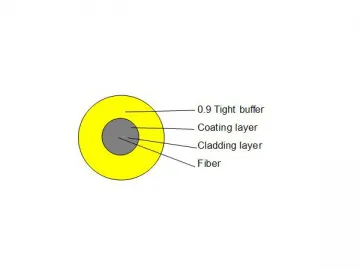

GJFJV 0.9 Fiber Optic Cable

GJFJV 0.9 Fiber Optic Cable

-

Flat Twin Duplex Fiber Optic Cable

Flat Twin Duplex Fiber Optic Cable

-

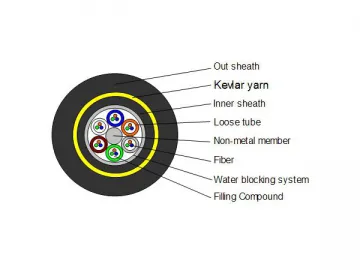

GYXTW Fiber Optic Cable

GYXTW Fiber Optic Cable