Flotation Process

Flotation Process

Theflotation process is commonly used for separation of both ferrous metal andnon-ferrous metal materials, such as copper ore, zinc ore, lead ore, nickelore, gold ore, and so on.

Processes

The ores are firstly roughly crushed by a jaw crusher, and then the materialsare delivered to a ball mill via a feeding system for further crushing andgrinding. Next, ball mill grinded materials will be conveyed to a spiralclassifier for classifying. After that, the classified materials are sent to aflotation machine, and different types of medications are added into thematerials according to the material property, and finally, the materials areseparated with each other. After concentration and filter pressing, the finalproducts are achieved.

Configuration of 25T/D FlotationSeparation System

| Equipment | Model | Quantity (set) | Power (kw) |

| Jaw crusher | 150×250 | 1 | 5.5 |

| Pendulum feeder | 400×400 | 1 | 1.5 |

| Ball mill | 900×3000 | 1 | 18.5 |

| Classifier | 750×6500 | 1 | 4 |

| Blender | 1000×1000 | 1 | 2.2 |

| Flotation machine | 3A | 24 cells | 0.55×6 3×24 |

Links:https://www.globefindpro.com/products/95202.html

-

80T/H-100T/H Stone Crushing Plant

80T/H-100T/H Stone Crushing Plant

-

400T/H-500T/H Stone Crushing Plant

400T/H-500T/H Stone Crushing Plant

-

Power Amplifier MP1510, MP2010, MP2510; MP3010, MP3510, MP4010

Power Amplifier MP1510, MP2010, MP2510; MP3010, MP3510, MP4010

-

Power Amplifier PC1700, PC2200, PC2700; PC3200, PC3700, PC4200

Power Amplifier PC1700, PC2200, PC2700; PC3200, PC3700, PC4200

-

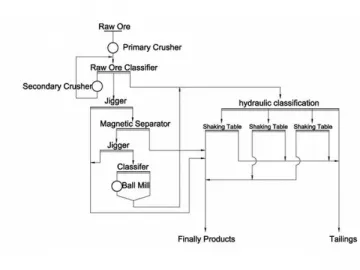

Beneficiation Process

Beneficiation Process

-

50T/H-80T/H Stone Crushing Plant

50T/H-80T/H Stone Crushing Plant

-

Dual Channel Power Amplifier MAG1306II, MAG1312II, MAG1325II, MAG1335II

Dual Channel Power Amplifier MAG1306II, MAG1312II, MAG1325II, MAG1335II

-

Wall Mounted Speaker HSD106

Wall Mounted Speaker HSD106

-

Wall Mounted Speaker HSD6061(B/W), HSD6062(B/W), HSD6063(B/W), HSD6064(B/W)

Wall Mounted Speaker HSD6061(B/W), HSD6062(B/W), HSD6063(B/W), HSD6064(B/W)

-

Wall Mounted Speaker HSD207

Wall Mounted Speaker HSD207

-

IP Media Matrix MAG5802

IP Media Matrix MAG5802

-

Ceiling Speaker HSD922, HSD922G

Ceiling Speaker HSD922, HSD922G