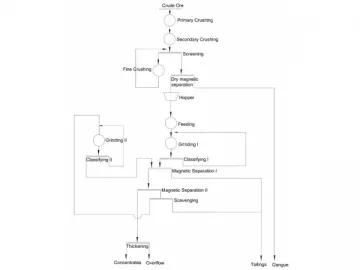

Magnetic Separation Process

Magnetic Separation Process

Equipment for Magnetic Separation Process

Magnetic separators arethe key equipment for use in magnetic separation process.

A magnetic separator canbe used for separation of a wide variety of materials such as magnetite, Martite, Hematite, cassiterite, oligonite, ilmenite, columbite, chromite, manganeseore, kaolin, quartz, rear earth and so on.

Principle and Applications

Magnetic separators usually separate the minerals by taking advantage of themagnetic intensity differences on non-uniform magnetic field.

Magnetic separation is widely used in the following areas:

1. The separation of ferrous metal materials

Magnetic separation process is the main processing way for iron ores. Aftermagnetic separation, the iron ores are given improved quality, reduceddetrimental impurity, which brings many benefits for the following smeltingprocess.

2. The separation of nonferrous and rare minerals

Nonferrous and rare minerals have varied magnetic intensity, so solely gravityseparation or solely flotation separation cannot achieve quality ores. Hence,magnetic separation, gravity separation and flotation separation are usuallyused in combination to obtain high grade minerals.

3. The media recovering in dense media separation

The magnetite and the ferrosilicon are the commonlyused medium during the dense media separation process. Magnetic separation isideal to recover the media lost in the process.

4. To remove iron impurities from non-metallic raw mineral materials

Iron removing can protect crushers and other related equipment and it is verycommon during nonmetallic mineral processing process. Magnetic separation isideal for iron removal. It can be used for the separation of Kyanite, quartz, red tourmaline, feldspar, and more for a longtime.

5. The recovery of steel slag produced during metallurgy smelting and pollutantremoval from sewage, etc.

A great amount of steel slag are produced in themetallurgy smelting process, and they can be recovered by dry type grinding anddry type magnetic separation. High gradient magnetic separation is commonlyused for impurity removal in waste water and sewage, etc.

100ts/d MagneticSeparation System for Iron Minerals

| Item | Model | Quantity (set) | Power (KW) | Remarks |

| Jaw crusher | PE400×600 | 1 | 30 |

|

| Jaw crusher | PEX250×1000 | 1 | 37 |

|

| Feeder | Ф600×600 or GZ 1 | 1 | 2.2 |

|

| Ball mill | Ф1500×3500 | 1 | 75 |

|

| Classifier | Ф750 | 1 | 5.5 | Replaceable |

| High frequency screen | GPS6 | 2 | 1.5×2 | |

| Magnetic separator | CTB918 | 1 | 4 |

|

| Magnetic separator | CTB718 | 1 | 3 |

|

500ts/d Magnetic Separation System for Iron Minerals

| Item | Model | Quantity (set) | Power(kw) | Remarks |

| Jaw crusher | PE500 × 750 | 1 | 55 |

|

| Fine jaw crusher | PEX250 × 1000 | 1 | 37 |

|

| Pendulum feeder | Ф600 × 600 | 1 | 2.2 |

|

| Ball mill | Ф2100 × 4000 | 1 | 245 |

|

| Classifier | Ф2000 | 1 | 7.5 | Replaceable |

| High frequency screen | GPS6 | 2 | 1.5 × 2 | |

| Magnetic separator | CTB1021 | 2 | 5.5 |

|

1000ts/d Magnetic Separation System for Iron Minerals

| Item | Model | Quantity (set) | Power ( KW ) | Remarks |

| Jaw crusher | PE600 × 900 | 1 | 75 |

|

| Fine jaw crusher | PEX250 × 1000 | 1 | 45 |

|

| Pendulum feeder | Ф800 × 800 | 1 | 3 |

|

| Ball mill | Ф2700 × 3600 | 1 | 400 |

|

| Classifier | Ф2000 | 1 | 15 | Replaceable |

| High frequency screen | GPS8.1 | 2 | 2.2 × 2 | |

| Magnetic separator | CTB1224 | 2 | 7.5 |

|

Links:https://www.globefindpro.com/products/95209.html

-

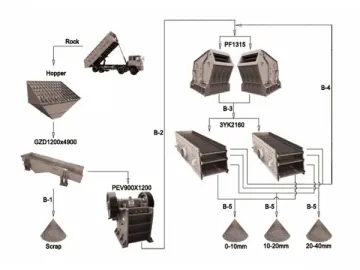

150T/H-200T/H Stone Crushing Plant

150T/H-200T/H Stone Crushing Plant

-

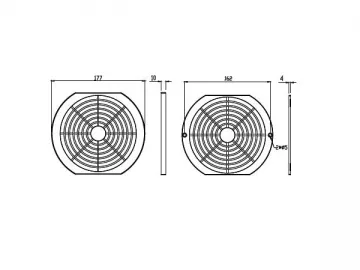

Plastic Fan Dust Filter

Plastic Fan Dust Filter

-

Power Amplifier MP6425, MP6438, MP6450

Power Amplifier MP6425, MP6438, MP6450

-

Mobile Impact Crusher

Mobile Impact Crusher

-

300T/H-400T/H Stone Crushing Plant

300T/H-400T/H Stone Crushing Plant

-

Power Amplifier MP1500, MP2000, MP2500; MP3000, MP3500, MP4000

Power Amplifier MP1500, MP2000, MP2500; MP3000, MP3500, MP4000

-

50T/H-80T/H Stone Crushing Plant

50T/H-80T/H Stone Crushing Plant

-

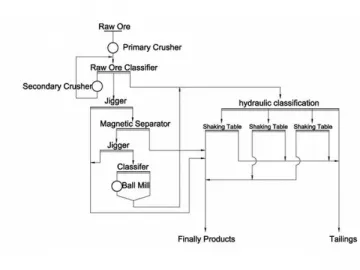

Beneficiation Process

Beneficiation Process

-

Power Amplifier PC1700, PC2200, PC2700; PC3200, PC3700, PC4200

Power Amplifier PC1700, PC2200, PC2700; PC3200, PC3700, PC4200

-

Power Amplifier MP1510, MP2010, MP2510; MP3010, MP3510, MP4010

Power Amplifier MP1510, MP2010, MP2510; MP3010, MP3510, MP4010

-

400T/H-500T/H Stone Crushing Plant

400T/H-500T/H Stone Crushing Plant

-

80T/H-100T/H Stone Crushing Plant

80T/H-100T/H Stone Crushing Plant