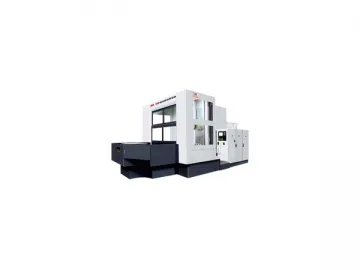

Vertical Machining Center, VMC850B, VMC1000B, VMC1100B

Innovative frame structure with high rigidity

The innovative frame structure of our vertical machining center feature high rigidity. Main components such as bed, columns, etc., incorporate cast iron with excellent vibration dampening and thermal characteristics for excellent rigidity and accuracy of machining.

Features

Novel frame structure with high rigidity

Innovative Frame Structure with high rigidity. Main components such as bed, columns, etc., all incorporate cast iron with excellent vibration dampening and thermal characteristics for excellent rigidity and accuracy of machining.

Rapid speed

The rapid speeds for X/Y/Z are 32/32/30 meters/minute. This is due to the incorporation of linear guideways, which minimizes non-cutting time, thus improving machining efficiency.

Easy-to-use control panel

Fanuc 0i-MD CNC system is easy to use, and the conveniently located control panel which swings 90 degrees makes the operation of the machine as effortless and intuitive as possible for the operator.

High accuracy, high quality spindle

Standard spindle is BT40, 8000 RPM. Optionally, BT50 6000 RPM spindle can be supplied with VMC1100B for heavier machining requirements.

Large Machining Envelope

The Z axis travel of 650 mm. makes the work-piece envelope much larger than other machines of the same table-size can provide.

| Model | Units | VMC850B | VMC1000B | VMC1100B | ||||

| Worktable | Worktable dimensions | mm | 1000×500 | 1200×500 | 1300×610 | |||

| T-slot sizes | mm | 18×5 | 18×5 | 18×5 | ||||

| Max load allowed | kg | 600 | 600 | 1000 | ||||

| Operating range | X-axis travel | mm | 850 | 1000 | 1100 | |||

| Y-axis travel | mm | 560 | 610 | 610 | ||||

| Z-axis travel | mm | 650 | 650 | 650 | ||||

| Max distance from spindle end face | mm | 800 | 800 | 800 | 774 | |||

| Mind stance from spindle end face | mm | 150 | 150 | 150 | 124 | |||

| Spindle | Taper shank of spindle 7:24 | 7:24 | BT40 | BT40 | BT40 | BT50 | ||

| Spindle speed | rpm | 8000 | 8000 | 8000 | 6000 | |||

| Main motor torque | Nm | 52.5 | 52.5 | 52.5 | ||||

| Main motor power | kW | 11/15 | 11/15 | 11/15 | ||||

| Feed | X/Y/Z-axis rapid speed | m/min | 32/32/30 | 32/32/30 | 32/32/30 | |||

| Feed speed | m/min | 20 | 20 | 20 | ||||

| Tool magazine | Tool magazine forms | mechanical arm | mechanical arm | mechanical arm | mechanical arm | |||

| Tools qty | pcs | 24 | 24 | 24 | 20 | |||

| Tool change time | s | 3.5 | 3.5 | 3.5 | 3.5 | |||

| Positioning accuracy | Perform the standard JB6330 | mm | ±0.005/300 | |||||

| Perform the standard JB/T8771.4 | mm | 0.016/0.012/0.012 | ||||||

| Repeatability | Perform the standard JB6330 | mm | ±0.003 | |||||

| Perform the standard JB/T8771.4 | mm | 0.010/0.008/0.008 | ||||||

| General power capacity | KVA | 25 | 25 | 25 | ||||

| Air-supply pressure | Mpa | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 | ||||

| Overall size and weight of the machine | Floor space(L×W) | mm | 2840×2565 | 2840×2565 | 2840×2565 | |||

| Machine height | mm | 2944 | 2944 | 2944 | ||||

| Machine weight | kg | 6000 | 6200 | 7000 | ||||

| Control system | FANUC | FANUC | FANUC | |||||

Note: The parameters in the list are for reference only, please subject to material object.

| Model | VMC850B | VMC1000B | VMC1100B | |

| 3-axis ball screws | ● | |||

| 3-axis guideway | X | Linear rail | Linear rail | Linear rail |

| Y | Linear rail | Linear rail | Linear rail | |

| Z | Linear rail | Linear rail | Linear rail | |

| stainless steel guideway protection | ● | ● | ● | |

| Full protective room | ● | ● | ● | |

| Chip removal system | Screw-type chip conveyor and water tank | |||

| Water tank | ● | ● | ● | |

| Chain-type chip conveyor | ▲ | ▲ | ▲ | |

| lubricating system | ● | ● | ● | |

| Pneumatic system | ● | ● | ● | |

| Air gun | ● | ● | ● | |

| Illuminating lamp of machine | ● | ● | ● | |

| 3-color alarm lamp | ● | ● | ● | |

| Cool-heat exchanger | ● | ● | ● | |

| Control system | FANUC | ● | ● | ● |

| Mitsubishi | ▲ | ▲ | ▲ | |

| SIEMENS | ▲ | ▲ | ▲ | |

| Fiyang | ▲ | ▲ | ▲ | |

| Internal cooling | 10BAR | ▲ | ▲ | ▲ |

| 20BAR | ▲ | ▲ | ▲ | |

| Reduction gearbox | ||||

| Tool detection | NC4 non-contact type Renishaw | ▲ | ▲ | ▲ |

| TS27R contact type Renishaw | ▲ | ▲ | ▲ | |

| TS30 contact type Marposs | ▲ | ▲ | ▲ | |

| Workpiece detection | OMP60 Renishaw | ▲ | ▲ | ▲ |

| E83 Marposs | ▲ | ▲ | ▲ | |

| Sealed encoder | ▲ | ▲ | ▲ | |

| Hydraulic monitor | ▲ | ▲ | ▲ | |

| Rotary table | ▲ | ▲ | ▲ | |

| Air condition | ▲ | ▲ | ▲ | |

| CE safety certificate | ▲ | ▲ | ▲ | |

| V-axis interface | ▲ | ▲ | ▲ | |

| Ethernet function | ● | ● | ● | |

| Ethernet function | BT40 20 Umbrella type | ▲ | ▲ | ▲ |

| BT40 24 Mechanical arm | ● | ● | ● | |

| BT50 16 Umbrella type | ||||

| BT50 20 Mechanical arm | ▲ | ▲ | ▲ | |

| BT50 3 chain type | ||||

| Spindle form | BT40 8000 revolutions | ● | ● | ● |

| BT40 10000 revolutions | ▲ | ▲ | ▲ | |

| BT50 6000 revolutions | ▲ | |||

Note: ●means standard. ▲ means optional, the space means absent.

| Item | VMC850B | VMC1000B | VMC1100B | |

| 3-axis ballscrews | ● | ● | ● | |

| 3-axis guideway | X | Linear guideway | Linear guideway | Linear guideway |

| Y | Linear guideway | Linear guideway | Linear guideway | |

| Z | Linear guideway | Linear guideway | Linear guideway | |

| Stainless-steel guideway protection | ● | ● | ● | |

| Full protective room | ● | ● | ● | |

| Chip removal system | Screw-type chip conveyor and water tank | |||

| Water tank | ● | ● | ● | |

| Chain-type chip conveyor | ▲ | ▲ | ▲ | |

| lubricating system | ● | ● | ● | |

| Pneumatic system | ● | ● | ● | |

| Air gun | ● | ● | ● | |

| Illuminating lamp of machine | ● | ● | ● | |

| 3-color alarm lamp | ● | ● | ● | |

| Cool-heat exchanger | ● | ● | ● | |

| CNC system | FANUC | ● | ● | ● |

| MITSUBISHI | ▲ | ▲ | ▲ | |

| SIEMENS | ▲ | ▲ | ▲ | |

| FIYANG | ▲ | ▲ | ▲ | |

| Internal cooling | 20BAR | ▲ | ▲ | ▲ |

| Reduction gearbox | ||||

| Tool detection | NC4 non-contact type Renishaw | ▲ | ▲ | ▲ |

| TS27R contact type Renishaw | ▲ | ▲ | ▲ | |

| TS30 contact type Marposs | ▲ | ▲ | ▲ | |

| Workpiece detection | OMP60 Renishaw | ▲ | ▲ | ▲ |

| E83 Marposs | ▲ | ▲ | ▲ | |

| X/Y/Z axis linear scale | ▲ | ▲ | ▲ | |

| Hydraulic monitor | ▲ | ▲ | ▲ | |

| Rotary table | ▲ | ▲ | ▲ | |

| Air condition | ▲ | ▲ | ▲ | |

| CE safety certificate | ▲ | ▲ | ▲ | |

| 4th axis interface | ▲ | ▲ | ▲ | |

| Ethernet function | ● | ● | ● | |

| Tool magazine form | BT40 20T Umbrella type | ▲ | ▲ | ▲ |

| BT40 24T Mechanical arm | ● | ● | ● | |

| BT50 16T Umbrella type | ||||

| BT50 20T Mechanical arm | ▲ | ▲ | ▲ | |

| BT50 32T chain type | ||||

| Spindle form | BT40 8000 revolutions | ● | ● | ● |

| BT40 10000 revolutions | ▲ | ▲ | ▲ | |

| BT50 6000 revolutions | ▲ | |||

Links:https://www.globefindpro.com/products/96271.html

-

Festoon bulb 42mm x 10mm

Festoon bulb 42mm x 10mm

-

Festoon bulb 36mm x 10mm

Festoon bulb 36mm x 10mm

-

LED Cup Light MR16/Mr11

LED Cup Light MR16/Mr11

-

LED Auto Light T25 (cornering lamps /stop lamp/fog lamp,tail lamp)

LED Auto Light T25 (cornering lamps /stop lamp/fog lamp,tail lamp)

-

LED Auto Light T25 (cornering lamps /stop lamp/fog lamp,tail lamp)

LED Auto Light T25 (cornering lamps /stop lamp/fog lamp,tail lamp)

-

Festoon bulb 31mm x 10mm

Festoon bulb 31mm x 10mm

-

Festoon bulb 31mm x 10mm

Festoon bulb 31mm x 10mm

-

LED Cup Light E27/E14

LED Cup Light E27/E14

-

LED Grow Light

LED Grow Light

-

HMC50, HMC63, HMC80 Horizontal Machining Center

HMC50, HMC63, HMC80 Horizontal Machining Center

-

LED Reading Lamp

LED Reading Lamp

-

LED Cup Light GU10

LED Cup Light GU10