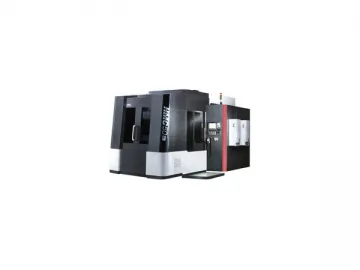

Vertical Turning Milling Center GTM-F, GTM

Vertical Turning Milling Center

GTM-F and GTM series machine tools arevertical turning milling centers designed by Shenyang/Schiess CNC Machine ToolBusiness unit. The general configuration of our turning milling center is fixedgantry (GTM series is with moving gantry), including double columns withconnecting brace, with the cross-rail capable of moving vertically up and downon the columns.

The internationally recognized quality of this vertical turning milling centeris derived from the modular designing and manufacturing technology developed byShiess. These machines have powerful machining capacity, and high levels ofmachining accuracy and efficiency. The fully automatic tool changing technologyhas helped resulted in the automatic capability of these turning millingmachines. The safety features coupled with the high accuracy of the controlsystem ensures the safety of both personnel and equipment.

Structure Features of Vertical Turning Milling Center

The main drive controls powerful double spindle motors with great range ofspeed. The motors are controlled as master and slave to eliminate backlash,especially critical during milling operations. The worktable is supportedhydrostatically, for maximum load capacity, reduced friction, high machiningaccuracy, and long service life.

Hydrostatic guide-ways are employed on the X and Y axes to increase rigidity,greatly improve positioning speed and accuracy, reduce friction, and prolongthe life of the components.

Our vertical turning milling center is capable of automatically exchangingwork-heads, for a variety of operations: straight boring and milling, rightangle boring and milling, multi-position turning turret, universal milling andboring head, etc, options as the user requires.

The ram indexing motor is compact in design, and is incorporated in the ramstructure in order to improve the reliability of the turning milling center.

Synchronous drive technology is used to position the cross-rail in the verticalaxis, which provides fast, smooth positioning, and therefore improved machiningaccuracy.

StandardAccessories, Optional Accessories of Vertical Turning Milling Center

| Item | GTC Series | GTM-F Series | GTM Series |

| Imported spindle bearing | ● | ● | ● |

| SINUMERIK 840D | ● | ● | ● |

| Manual 4-jaw independent worktable | ● | ● | ● |

| C-axis worktable | - | ● | ● |

| Hydrostatic guideway of X/Z-axis | ● | ● | ● |

| Imported ballscrew | ● | ● | ● |

| Single ram | ● | ● | ● |

| Air-conditioner in the electrical cabinet | ● | ● | ● |

| X-axis scale | ● | ● | ● |

| Z-axis scale | ● | ● | ● |

| W-axis scale | ● | ● | ● |

| Y-axis scale | - | - | ● |

| Hydraulic station | ● | ● | ● |

| Constant temperature cooling tank | ● | ● | ● |

| Upgrading device for cooling | ● | ● | ● |

| Pneumatic device | ● | ● | ● |

| Chip conveyor | ● | ● | ● |

| Cooling device | ● | ● | ● |

| Electrical device | ● | ● | ● |

| Outside protection | ● | ● | ● |

| 12 stations discal tool magazine | ● | ★ | ★ |

| Turning & milling compound tool magazine (6 28 stations) | - | ● | ● |

| Chain-type milling tool magazine | ★ | ★ | ★ |

| Special turning tool magazine | ★ | ★ | ★ |

| Special head magazine | ★ | ★ | ★ |

| C-axis function | - | ● | ● |

| Chip conveyor (Chain-type) | ● | ● | ● |

| Oil-water segregator | ● | ● | ● |

| Grounded operation panel | ● | ● | ● |

| Workpiece measurement | ★ | ★ | ★ |

| Tool detection | ★ | ★ | ★ |

| Standard tool holder | ● | ● | ● |

| Special tool holder | ★ | ★ | ★ |

| Straight boring & milling head | - | ● | ● |

| Right angle boring & milling head | - | ★ | ★ |

| Universal boring & milling head | - | ★ | ★ |

| Handle operation panel B-MPI | ★ | ★ | ★ |

| Positioning adapter | ★ | ★ | ★ |

| Multi stations tool turret | ★ | ★ | ★ |

| Square worktable | - | - | ★ |

| ● Standard Accessories ★ Optional Accessories | |||

Main TechnicalSpecifications

| Item | Units | GTM-F Series Vertical Turning Milling Center | |||||

| GTM 160140/160f | GTM200140/160f | GTM250140/160f | GTM320140/160f | GTM430140/160f | |||

| Worktable diameter | mm | 125 | 1600/1800 | 2000/2250 | 2500/2800 | 3200/3500 | |

| Max. swing diameter | mm | 160 0 | 2000 | 2500 | 3200 | 4300 | |

| Max. machining diameter | mm | 160 0 | 2000 | 2500 | 3200 | 4300 | |

| Distance between double columns | mm | 144 0 | 1840 | 2340 | 3040 | 4540 | |

| Workpiece height | mm | 160 0 | 2000 | 2000 | 2500 | 3000 | |

| Max. cutting force | kN | 50 | 50 | 50 | 50 | 50 | |

| Max. workpiece weight | ton | 10 | 15 | 20 | 25 | 40 | |

| Motor power | kW/AC | 110 (=55 ×2) | 110(=55×2) | 110(=55×2) | 110(=55×2) | 110(=55×2) | |

| Worktable | Max. turning speed | rpm | 0-33 5 | 0-265 | 0-200 | 0-180 | 0-120 |

| Milling speed (C-axis) | rpm | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | |

| Max. worktable torque | kNm | 37.5 | 48 | 58 | 70 | 50 | |

| Jaw quantity |

| 4 | 4 | 4 | 4 | 4 | |

| Ram | Section size | mm | 240 ×280 | 240×280 | 240×280 | 240×280 | 240×280 |

| Min. turning hole diameter when the ram extending | mm | 375 | 375 | 375 | 375 | 375 | |

| Travel | Slide travel (X-axis) |

| -110 0/ 2095 | -0.590909091 | -0.588235294 | -0.678571429 | -0.714285714 |

| Ram travel (Z-axis) | mm | 140 0/16 00 | 1400/1600 | 1400/1600 | 1400/1600 | 1400/1600 | |

| Gantry travel (Y-axis) | mm | - | - | - | - | - | |

| Crossbeam travel (W-axis) | mm | 100 0 | 1400 | 1400 | 1700 | 1800 | |

| Feed speed | Feed speed (X/Z-axis) | mm/min | 0-16 000 | 0-16000 | 0-16000 | 0-16000 | 0-16000 |

| Feed speed (Y-axis) | mm/min | - | - | - | - | - | |

| Rapid traverse | Rapid speed (X/Z-axis) | mm/min | 160 00 | 16000 | 16000 | 16000 | 16000 |

| Gantry rapid speed (Y-axis) | mm/min | - | - | - | - | - | |

| Crossbeam rapid speed (W-axis) | mm/min | 400 0 | 4000 | 4000 | 4000 | 4000 | |

| Boring & Milling spindle | Max. speed | rpm | 315 0 | 3150 | 3150 | 3150 | 3150 |

| Max. torque | Nm | 240 0 | 2400 | 2400 | 2400 | 2400 | |

| Power (100%) | kW | 52 | 52 | 52 | 52 | 52 | |

| Shank ISO |

| 50 | 50 | 50 | 50 | 50 | |

| Tool magazine | Attachment head magazine | Station | 6 | 6 | 6 | 6 | 6 |

| Milling tool magazine | Station | 28(horizontal 6 stations, vertical 22 stations) | |||||

| Item | Units | GTM Series Gantry Moving Vertical Turning Milling Center | |||||

| GTM160 140/160 | GTM200 140/160 | GTM250 140/160 | GTM320 140/160 | GTM430 140/160 | |||

| Worktable diameter | mm | 1250/1400 | 1600/1800 | 2000/2250 | 2500/2800 | 3200/3500 | |

| Max. swing diameter | mm | 1600 | 2000 | 2500 | 3200 | 4300 | |

| Max. machining diameter | mm | 1600 | 2000 | 2500 | 3200 | 4300 | |

| Distance between double columns | mm | 1440 | 1840 | 2340 | 3040 | 4540 | |

| Workpiece height | mm | 1600 | 2000 | 2000 | 2500 | 3000 | |

| Max. cutting force | kN | 50 | 50 | 50 | 50 | 50 | |

| Max. workpiece weight | ton | 10 | 15 | 20 | 25 | 40 | |

| Motor power | kW/AC | 110(=55×2) | 110(=55×2) | 110(=55×2) | 110(=55×2) | 110(=55×2) | |

| Worktable | Max. turning speed | rpm | 0-335 | 0-265 | 0-200 | 0-180 | 0-120 |

| Milling speed (C-axis) | rpm | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | |

| Max. worktable torque | kNm | 37.5 | 48 | 58 | 70 | 50 | |

| Jaw quantity |

| 4 | 4 | 4 | 4 | 4 | |

| Ram | Section size | mm | 240×280 | 240×280 | 240×280 | 240×280 | 240×280 |

| Min. turning hole diameter when the ram extending | mm | 375 | 375 | 375 | 375 | 375 | |

| Travel | Slide travel (X-axis) |

| -0.525059666 | -0.590909091 | -0.607843137 | -0.678571429 | -0.704225352 |

| Ram travel (Z-axis) | mm | 1400/1600 | 1400/1600 | 1400/1600 | 1400/1600 | 1400/1600 | |

| Gantry travel (Y-axis) | mm | ±800 | ±1000 | ±1250 | ±1600 | ±2150 | |

| Crossbeam travel (W-axis) | mm | 1000 | 1400 | 1400 | 1700 | 1800 | |

| Feed speed | Feed speed (X/Z-axis) | mm/min | 0-16000 | 0-16000 | 0-16000 | 0-16000 | 0-16000 |

| Feed speed (Y-axis) | mm/min | 0-8000 | 0-8000 | 0-8000 | 0-8000 | 0-8000 | |

| Rapid traverse | Rapid speed (X/Z-axis) | mm/min | 16000 | 16000 | 16000 | 16000 | 16000 |

| Gantry rapid speed (Y-axis) | mm/min | 8000 | 8000 | 8000 | 8000 | 8000 | |

| Crossbeam rapid speed (W-axis) | mm/min | 4000 | 4000 | 4000 | 4000 | 4000 | |

| Boring & Milling spindle | Max. speed | rpm | 3150 | 3150 | 3150 | 3150 | 3150 |

| Max. torque | Nm | 2400 | 2400 | 2400 | 2400 | 2400 | |

| Power (100%) | kW | 52 | 52 | 52 | 52 | 52 | |

| Shank ISO |

| 50 | 50 | 50 | 50 | 50 | |

| Tool magazine | Attachment head magazine | Station | 6 | 6 | 6 | 6 | 6 |

| Milling tool magazine | Station | 28(horizontal 6 stations, vertical 22 stations) | |||||

Links:https://www.globefindpro.com/products/96289.html

-

Slant Bed CNC Lathe, HTC40n, HTC50n

Slant Bed CNC Lathe, HTC40n, HTC50n

-

Flat Bed CNC Lathe CAK3675 Series, CAK50100 Series

Flat Bed CNC Lathe CAK3675 Series, CAK50100 Series

-

Vertical Machining Center VMC1300B

Vertical Machining Center VMC1300B

-

HMC-h Horizontal Machining Center

HMC-h Horizontal Machining Center

-

CNC Vertical Turning Machine Vertiturn Series

CNC Vertical Turning Machine Vertiturn Series

-

Slant Bed CNC Lathe, HTC50

Slant Bed CNC Lathe, HTC50

-

Horizontal Machining Center, HMC100, HMC125/125s/125140s, HMC160/160rd

Horizontal Machining Center, HMC100, HMC125/125s/125140s, HMC160/160rd

-

Festoon bulb 36mm x 10mm

Festoon bulb 36mm x 10mm

-

Vertical Machining Center VMC700B

Vertical Machining Center VMC700B

-

T10 Instrument bulb

T10 Instrument bulb

-

Vertical Machining Center, VMC0656mu, VMC0875mu, VMC0995mu

Vertical Machining Center, VMC0656mu, VMC0875mu, VMC0995mu

-

LED Reading Lamp

LED Reading Lamp