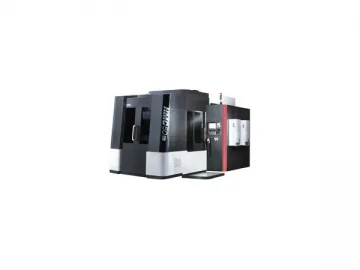

HMC-h Horizontal Machining Center

HMC-h series high speed horizontal machining center has double pallets exchanging function and characteristics of high speed, high precision and high reliability. It can be widely applied in the fields of automobile, motorcycle, hydraulic components, etc. This horizontal machining center is the ideal equipment for machining box type part, shell, valve, etc., and especially suitable for the whole set production line of automobile cylinder body, cylinder head, gear box case, etc.

Our horizontal machining center is designed with a typical box-in-box structure which features high rigidity and rapid response.

The application of double exchanging pallets structure greatly shortens the part loading time, therefore improves the production efficiency.

The unique pallet exchanger structure guarantees the rapidity and precision of pallet exchanging and significantly reduces maintenance cost of part change in the future for the user.

The linear axial rapid feed speed reaches 60m/min and the acceleration reaches 1g, which significantly shortens non-cutting time of the machining center.

The quick tool changing device can greatly satisfy the needs for productive tempo in the automobile production line.

Specifications of Horizontal Machining Center

| Model | Units | HMC50h | ||

| Worktable | Worktable size | mm | 500×500 | |

| Worktable load | kg | 600(uniformly distributed) | ||

| Number of worktable | 2(changing pallets) | |||

| Changing time | s | 8 | ||

| Machining range | X axis | mm | 630 | |

| Y axis | mm | 630 | ||

| Z axis | mm | 630 | ||

| Worktable rotation-B axis | 0.001° | |||

| Max. swing dia. of workpiece | mm | φ710(500×500) | ||

| Max. height of workpiece | mm | 820 | ||

| Distance between spindle end surface and worktable center | mm | 160-790 | ||

| Distance between spindle center and worktable surface | mm | 130-760 | ||

| Spindle | Rotating speed range (stepless) | r/min | 10-18000 | |

| Max. output torque | N.m | 85/130 | ||

| Spindle motor power | kW | 25/35 | ||

| Max. axial resisting force of spindle | N | 8000 | ||

| Feed | Feed speed range during machining X,Y,Z | mm/min | 1-60000 | |

| Rapid feed | X axis | m/min | 60 | |

| Y axis | m/min | 60 | ||

| Z axis | m/min | 60 | ||

| Tool magazine and automatic tool changing device | Tool magazine capacity | Pcs | 40 | |

| Tool selection method | kg | Supplied with machine | ||

| Max. tool weight | mm | 8 | ||

| Max. tool length | mm | 350 | ||

| Max. tool diameter | s | φ80(when next pocket is emptyφ160) | ||

| Tool changing time | 2.5(T-T) | |||

| Tool shank specification | mm | HSK-A63 | ||

| Positioning accuracy of machine | X, Y, Z axes | 0.006 | ||

| B axis | mm | 8 | ||

| Repeatability positioning accuracy | X, Y, Z axes | 0.004 | ||

| B axis | 5 | |||

| System | CNC system | SIEMENS 840D | ||

Links:https://www.globefindpro.com/products/96293.html

-

CNC Vertical Turning Machine Vertiturn Series

CNC Vertical Turning Machine Vertiturn Series

-

Slant Bed CNC Lathe, HTC50

Slant Bed CNC Lathe, HTC50

-

HTC2050n Horizontal-axis CNC Lathe

HTC2050n Horizontal-axis CNC Lathe

-

Slant Bed CNC Lathe, HTC1608

Slant Bed CNC Lathe, HTC1608

-

Flat Bed CNC Lathe, CAK16/36/40 Series

Flat Bed CNC Lathe, CAK16/36/40 Series

-

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

-

Vertical Machining Center VMC1300B

Vertical Machining Center VMC1300B

-

Flat Bed CNC Lathe CAK3675 Series, CAK50100 Series

Flat Bed CNC Lathe CAK3675 Series, CAK50100 Series

-

Slant Bed CNC Lathe, HTC40n, HTC50n

Slant Bed CNC Lathe, HTC40n, HTC50n

-

Vertical Turning Milling Center GTM-F, GTM

Vertical Turning Milling Center GTM-F, GTM

-

Horizontal Machining Center, HMC100, HMC125/125s/125140s, HMC160/160rd

Horizontal Machining Center, HMC100, HMC125/125s/125140s, HMC160/160rd

-

Festoon bulb 36mm x 10mm

Festoon bulb 36mm x 10mm