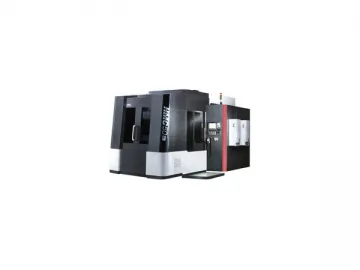

CNC Vertical Turning Machine Vertiturn Series

Introduction

The VERTITURN vertical turning machine is designed and developed by the Shenyang-Schiess CNC Machine Tool business unit of SMTCL, and is suitable for the medium-priced market. The general configuration of this CNC turning machine is a gantry-frame made of two columns and a cross brace. The cross-rail moves vertically along the columns. By adopting the superb designing and manufacturing technologies of Schiess, these CNC turning machines have the advantages of high quality, powerful machining capability, high machining accuracy and efficiency. The fully automatic tool changing technology contributes to the full automation of the machine. Protective features and the high accuracy of the control contribute to the safety of both personnel and equipment.

Main Features of CNC Vertical Turning Machine

The design of this CNC turning machine helps achieve both high precision and heavy cutting. The design of the casting reduces vibration. Double column with brace construction makes for stable structure which improves machining quality. Symmetrical construction makes for more even heat distribution and higher accuracy. X-axis incorporates linear roller bearings for low friction and high accuracy. Ball screws are of large size to enhance the rigidity of the transfer of power into motion.

Linear encoders are incorporated into both the X and Z axes. Angular contact bearings and axial thrust bearings are preloaded. The main drive controls double motors on the spindle such that they pre-load the rotation of the table during milling operations.

Applications

VERTITURN series CNC vertical turning machine is mainly designed for the accurate machining of large disc shaped work-pieces using multiple operations, for the fields of aerospace, ship-building, wind power generation, military, mining, bearing manufacturing, valve manufacturing, etc. Using this series of CNC turning machine, operations with other machines may be eliminated, set-up and production times can be reduced, accuracy can be increased, and overall productivity will be improved.

Main Technical Specifications of CNC Vertical Turning Machine

| Item | Units | VERTITURN 1 | VERTITURN 2 | VERTITURN 3 | ||||

| Turning machine | Turning and milling | Turning machine | Turning and milling | Turning machine | Turning and milling | |||

| Worktable dia. | mm | φ1250 | φ1250 | φ1600 | φ1600 | φ2000 | φ2000 | |

| Max. turning dia. | mm | φ1600 | φ1600 | φ2000 | φ2000 | φ2500 | φ2500 | |

| Max. turning height | mm | 1200 | 1200 | 1200 | 1200 | 1600/2000/2500 | 1600/2000/2500 | |

| Max. weight of workpiece | ton | 8 | 8 | 12 | 12 | 16 | 16 | |

| Main motor power | kW | 60 | Turning 60/ Milling 29 | 60 | Turning 60/ Milling 29 | 60 | Turning 60/Milling 29 | |

| Max. rotary speed of worktable | rpm | 500 | 500 | 345 | 345 | 225 | 225 | |

| Ram size | mm | 280×280 | 280×280 | 280×280 | 280×280 | 280×280 | 280×280 | |

| Ram travel | mm | 1000 | 1000 | 1000 | 1000 | 1400/16 00 | 1400/1600 | |

| C-axis speed | rpm | 0.01-7.0 | 0.01-6.0 | 0.01-5.0 | ||||

| Max. cutting force | kN | 25 | 25 | 25 | 25 | 30 | 30 | |

| Milling motor power | kW | 28 | 28 | 28 | ||||

| Min. boring dia. | mm | 400 | 400 | 400 | 400 | 400 | 400 | |

| Max. speed of milling axis | rpm | 2400 | 2400 | 2400 | ||||

| X-axis max. rapid speed | mm/min | 16000 | 16000 | 16000 | 16000 | 16000 | 16000 | |

| Z-axis max. rapid speed | mm/min | 8000 | 8000 | 8000 | 8000 | 8000 | 8000 | |

| Vertical travel of crossbeam | mm | 1000 | 1000 | 1000 | 1000 | 1400 | 1400 | |

| Moving speed of crossbeam | mm/min | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | |

| Overall dimensions | L | mm | 6784 | 6784 | 7784 | 7784 | 8784 | 8784 |

| W | mm | 5000 | 5000 | 5675 | 5675 | 6675 | 6675 | |

| H | mm | 5300 | 5300 | 6000 | 6000 | 6782 | 6782 | |

| Machine weight | ton | 45 | 45 | 50 | 50 | 55 | 55 | |

Main Technical Specifications of Turning Milling Center

| Item | Units | VERTITURN 4 | VERTITURN 5 | VERTITURN 6 | ||||

| Turning machine | Turning and milling | Turning machine | Turning and milling | Turning machine | Turning and milling | |||

| Worktable dia. | mm | φ2500 | φ2500 | φ3000 | φ3000 | φ3500 | φ3500 | |

| Max. turning dia. | mm | φ3000 | φ3000 | φ3500 | φ3500 | φ4000 | φ4000 | |

| Max. turning height | mm | 2000/2500 | 2000/2500 | 2000/2500 | 2000/2500 | 2000/ 2500 | 2000/ 2500 | |

| Max. weight of workpiece | ton | 20 | 20 | 25 | 25 | 30 | 30 | |

| Main motor power | kW | 60 | Turning 60/ Milling 29 | 71 | Turning 71/ Milling 29 | 71 | Turning 71/ Milling 29 | |

| Max. rotary speed of worktable | rpm | 195 | 195 | 150 | 150 | 128 | 128 | |

| Ram size | mm | 280×280 | 280×280 | 280×280 | 280×280 | 280×280 | 280×280 | |

| Ram travel | mm | 1400/1600 | 1400/1600 | 1400/1600 | 1400/1600 | 1400/1600 | 1400/1600 | |

| C-axis speed | rpm | 0.01-4.0 | 0.01-4.0 | 0.01-4.0 | ||||

| Max. cutting force | kN | 30 | 30 | 30 | 30 | 30 | 30 | |

| Milling motor power | kW | 28 | 28 | 28 | ||||

| Min. boring dia. | mm | 400 | 400 | 400 | 400 | 400 | 400 | |

| Max. speed of milling axis | rpm | 2400 | 2400 | 2400 | ||||

| X-axis max. rapid speed | mm/min | 16000 | 16000 | 16000 | 16000 | 16000 | 16000 | |

| Z-axis max. rapid speed | mm/min | 8000 | 8000 | 8000 | 8000 | 8000 | 8000 | |

| Vertical travel of crossbeam | mm | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | |

| Moving speed of crossbeam | mm/min | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | |

| Overall dimensions | L | mm | 9784 | 9784 | 10784 | 10784 | 11784 | 11784 |

| W | mm | 7675 | 7675 | 8675 | 8675 | 9675 | 9675 | |

| H | mm | 7500 | 7500 | 8200 | 8200 | 9000 | 9000 | |

| Machine weight | ton | 60 | 60 | 65 | 65 | 70 | 70 | |

Links:https://www.globefindpro.com/products/96294.html

-

Slant Bed CNC Lathe, HTC50

Slant Bed CNC Lathe, HTC50

-

HTC2050n Horizontal-axis CNC Lathe

HTC2050n Horizontal-axis CNC Lathe

-

Slant Bed CNC Lathe, HTC1608

Slant Bed CNC Lathe, HTC1608

-

Flat Bed CNC Lathe, CAK16/36/40 Series

Flat Bed CNC Lathe, CAK16/36/40 Series

-

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

-

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

-

HMC-h Horizontal Machining Center

HMC-h Horizontal Machining Center

-

Vertical Machining Center VMC1300B

Vertical Machining Center VMC1300B

-

Flat Bed CNC Lathe CAK3675 Series, CAK50100 Series

Flat Bed CNC Lathe CAK3675 Series, CAK50100 Series

-

Slant Bed CNC Lathe, HTC40n, HTC50n

Slant Bed CNC Lathe, HTC40n, HTC50n

-

Vertical Turning Milling Center GTM-F, GTM

Vertical Turning Milling Center GTM-F, GTM

-

Horizontal Machining Center, HMC100, HMC125/125s/125140s, HMC160/160rd

Horizontal Machining Center, HMC100, HMC125/125s/125140s, HMC160/160rd