Flat Bed CNC Lathe, CAK16/36/40 Series

This flat bed CNC lathe is equipped with high-accuracy bearings and ball-screws, 3-jaw manual chuck, vertical 4-way tool turret, automatic lubrication system, and manual tailstock. Very rigid single-spindle headstock, combined with variable-frequency spindle motor, can stand up to the most demanding cutting requirements.

Available CNC systems include FANUC, SIEMENS, GANZHOU CNC, HUA ZHONG, and OMORI, customers can choose according to their specific requirements.

Waterproof Design

In the design of protective guarding, labyrinth-style joints are created in such places as where the doors meet, where the ball-screw cover and the guard of the headstock meet, for example. Splash guards are also located on the pedestals of the CNC lathe, all of which improves the water resistant character of the entire machine.

The design of the overall guarding structure also maximizes the inner work-area of the CNC lathe, so there is more space for special accessories and tooling, also making the machining of special or odd-shaped parts easier.

Safe and Reliable Electrical Design

The electrical cabinet of our CNC lathe is well-designed and is simple in structure, with good closure and sealing characteristics.

The door incorporates a two-point lock for operator safety.

The internal design of the cabinet is clean and elegant, and its DC unit incorporates an integrated circuit board, with neat wiring and great reliability.

Design Features of the Spindle

The spindle realizes step-less speed change via frequency modulation, and can therefore accomplish constant surface speed machining. The front support for the spindle has triple angular contact bearing, and can withstand considerable radial and axial forces. The spindle power train includes a heavy, narrow V-belt, smooth drive system, little thermal distortion, and stable accuracy.

Lubricating Mode

This series of flat bed CNC lathe incorporates an automatic lubrication system whose output varies according to actual travel of the axes, thus ensuring sufficient lubrication for each way while saving much lubrication oil over time.

X-axis, Z-axis

X-axis and Z-axis are equipped with high-quality ball screws on both axes, with gibs and low-friction plastic material, and 45 degree locking nuts. The rapid speeds are much quicker (6m/min. for X, 10m/min. for Z), and double waterproof structure prolongs the life of bearings and ball-screws, and improves the overall performance of the flat bed CNC lathe.

Main Technical Specifications of Flat Bed CNC Lathe

| Item Unit | CAK3665(i, j ) | CAK4085i | CAK4085j | ||

| Max. swing diameter over bed | mm | φ360 | φ400 | φ400 | |

| Max. swing diameter over slide | mm | φ180 | φ200 | φ200 | |

| Max. cutting diameter over slide | mm | φ180 | φ200 | φ200 | |

| Max. cutting diameter | mm | 360 (vertical 4-position)/ 320 (horizontal 6-position) | 400 (vertical 4-position)/ 320 (horizontal 6-position) | 400 (vertical 4-position)/ 320 (horizontal 6-position) | |

| Max. turning length | mm | 650 (vertical 4-position)/ 550 (horizontal 6-position) | 850 (vertical 4-position)/ 750 (horizontal 6-position) | 850 (vertical 4-position)/ 750 (horizontal 6-position) | |

| Diameter of spindle bore | mm | φ53 | φ53 | φ53 | |

| Spindle nose | A6 | A6 | A6 | ||

| Main motor power (frequency-change) | kW | 5.5 | 7.5 | 5.5 | |

| Spindle speed | n | stepless, no gearshift | stepless, no gearshift | manual 3- gearshift, stepless in each gearshift | |

| Spindle speed range | Manual chuck | r/min | 200-2000 ● | 200-1600 ● | I 150-520 II440-1153 III770-1600 ● |

| Hydraulic chuck | r/min | 200-3000 ★ | 200-2400 ★ | I 150-520 II440-1153 III770-2000 ★ | |

| Diameter of tailstock sleeve | mm | φ60 | φ60 | φ60 | |

| Travel of tailstock sleeve | mm | 140 | 140 | 140 | |

| Taper bore of tailstock sleeve | Morse 4# | Morse 4# | Morse 4# | ||

| X axis travel | mm | 220 | 220 | 220 | |

| Z axis travel | mm | 650 | 850 | 850 | |

| X/Z axis rapid speed | m/min | 6/10 | 6/10 | 6/10 | |

| Turret form | Vertical 4-position | ||||

| Horizontal 6-position | ★ | ★ | ★ | ||

| Size of tool shank | Ex. circle tool | mm | 20×20 | 20×20 | 20×20 |

| Boring tool | mm | φ32 | φ32 | φ32 | |

| X/Z axis repeatability | 0.012/0.016 | 0.012/0.016 | 0.012/0.016 | ||

| Machining accuracy | IT6-IT7 | IT6-IT7 | IT6-IT7 | ||

| Steady rest | mm | φ30-φ80 ★ | φ30-φ80 ★ | φ30-φ80 ★ | |

| Following rest | mm | unavailable | φ30-φ80 ★ | φ30-φ80 ★ | |

| Total capacity of power supply | KVA | 15 | 15 | 15 | |

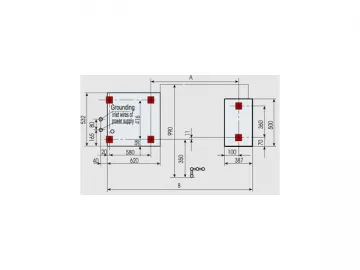

| Overall external dimensions of machine (L×W×H) | mm | 2220×1400×1600 | 2470×1400×1600 | 2470×1400×1600 | |

| Net/Gross weight of machine | kg | 1860/2110 | 1990/2290 | 1990/2290 | |

| Packing dimensions (L×W×H) | mm | 2520×1660×2050 | 2770×1660×2050 | 2770×1660×2050 | |

Links:https://www.globefindpro.com/products/96300.html

-

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

-

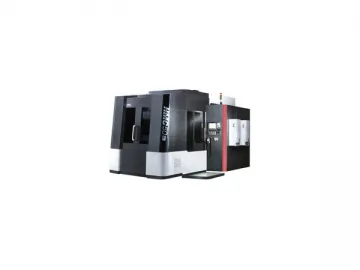

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

-

Slant Bed CNC Lathe, HTC32, HTC45, HTC54 Series

Slant Bed CNC Lathe, HTC32, HTC45, HTC54 Series

-

Slant Bed CNC Lathe, HTC16

Slant Bed CNC Lathe, HTC16

-

Conventional Lathe CA Series

Conventional Lathe CA Series

-

Horizontal CNC Lathe ETC-h Series

Horizontal CNC Lathe ETC-h Series

-

Slant Bed CNC Lathe, HTC1608

Slant Bed CNC Lathe, HTC1608

-

HTC2050n Horizontal-axis CNC Lathe

HTC2050n Horizontal-axis CNC Lathe

-

Slant Bed CNC Lathe, HTC50

Slant Bed CNC Lathe, HTC50

-

CNC Vertical Turning Machine Vertiturn Series

CNC Vertical Turning Machine Vertiturn Series

-

HMC-h Horizontal Machining Center

HMC-h Horizontal Machining Center

-

Vertical Machining Center VMC1300B

Vertical Machining Center VMC1300B