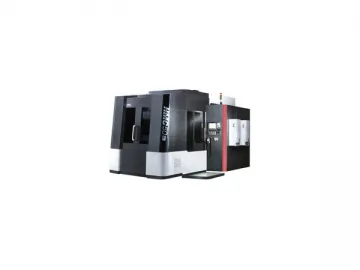

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

Our CNC lathe is designed and developed complying with the market demand, and is a mainstream product. The design for this machine tool aims to maximally satisfy the demands of customer. This CNC lathe applies integrated slant bed of 75° in order to make the machining position of the machine maximally close operators. In addition, the steady rest is normal to the floor, which on the one hand is convenient for customers installing, on the other hand avoids the damage of the steady rest due to mistaken operation. Advanced finite element analysis and dynamic stiffness and thermal stability analysis ensure the accuracy of the machine, which will make these series of slant bed CNC lathe become a leader in the industry.

Features

1. The machining position of the lathe is close to the operator, with conveniences on operation.

2. The steady rest adopts vertical layout, easy to clamp and unclamp the parts, with high safety.

3. High rigidity, large torque and well stability of machining accuracy.

| Item Unit | HTC50t series | HTC63t series HTC80t series | HTC100t series | ||

| Max. cutting length | mm | 2500 | 3000 | 3000 | |

| Max. swing over bed | mm | 700 | 900 | 1000 | 1100 |

| Max. cutting dia. | mm | 500 | 630 | 800 | 950 |

| Max. swing over slide | mm | 500 | 630 | 800 | 950 |

| Form and code of spindle nose | A2-8/A2-11 | A2-11 | A2-11 | A2-11 | |

| Dia. of spindle nose | mm | 80/104 | 104 | 130 | 130 |

| Range of spindle speed/Max. output torque of spindle/Steps of spindle speed | r/min/Nm | 30-2000/850/stepless | 20-1600/1600/stepless | 20-1200/2500/2 | 20-1500/2743/stepless |

| Output power of main motor (30min/rated) | kW | 30(FANUC) | 18.5/22(FANUC) | 45 | |

| Output power of main motor (Continuous rated value) | kW | 22(FANUC) | 13/18.5(FANUC) | 37 | |

| Chuck diameter | inch | 12"/15" | 15" | 21" | |

| Rapid traveling speed of X/Y/Z axis | m/min | 12/12 | 10/12 | ||

| Travel of X/Y axis | m/min | 270 | 325 | 410 | 675 |

| Travel of Z axis | mm | 2600 | 3100 | 3100 | 3050 |

| Max. thrust force of tailstock sleeve | N | 15000 | 20000 | 30000 | |

| Tailstock travel | mm | 2000 | 2000 | 2500 | 2700 |

| Form of turret | Horizontal 12-position | 12-position | |||

| Max. weighted load (disc/shaft workpiece) | kg | 200/800 | 500/2000 | 1000/4000 | |

| Machining accuracy | IT6 | IT6 | |||

| Surface roughness of workpiece | μm | Ra1.6 | Ra1.6 | ||

| Positioning accuracy of X/Y axis | mm | 0.011 | 0.013 | 0.013 | 0.016 |

| Positioning accuracy of Z axis | mm | 0.040 | 0.040 | 0.040 | 0.040 |

| Repositioning for X/Y axis | mm | 0.006 | 0.006 | 0.006 | 0.007 |

| Repositioning for Z axis | mm | 0.020 | 0.018 | 0.018 | 0.013 |

| Machine weight (net weight) | kg | 20000 | 23000 | 28000 | 38500 |

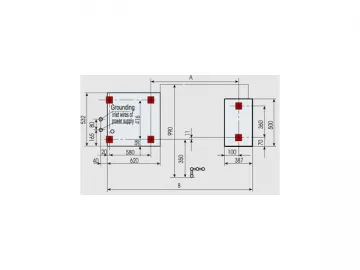

| Overall dimensions of machine L×W×H (Not include chip conveyor) | mm | 6100×2900×2750 (2500) | 9000×3130×3100 (3000) | 9342×3130×3100 (3000) | 9470×2910×3680 (3000) |

| Power of general power supply | kVA | 45 | 70 | 70 | 87 |

Links:https://www.globefindpro.com/products/96302.html

-

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

-

Slant Bed CNC Lathe, HTC32, HTC45, HTC54 Series

Slant Bed CNC Lathe, HTC32, HTC45, HTC54 Series

-

Slant Bed CNC Lathe, HTC16

Slant Bed CNC Lathe, HTC16

-

Conventional Lathe CA Series

Conventional Lathe CA Series

-

Horizontal CNC Lathe ETC-h Series

Horizontal CNC Lathe ETC-h Series

-

Slant Bed CNC Lathe, HTC32n

Slant Bed CNC Lathe, HTC32n

-

Flat Bed CNC Lathe, CAK16/36/40 Series

Flat Bed CNC Lathe, CAK16/36/40 Series

-

Slant Bed CNC Lathe, HTC1608

Slant Bed CNC Lathe, HTC1608

-

HTC2050n Horizontal-axis CNC Lathe

HTC2050n Horizontal-axis CNC Lathe

-

Slant Bed CNC Lathe, HTC50

Slant Bed CNC Lathe, HTC50

-

CNC Vertical Turning Machine Vertiturn Series

CNC Vertical Turning Machine Vertiturn Series

-

HMC-h Horizontal Machining Center

HMC-h Horizontal Machining Center