Slant Bed CNC Lathe, HTC32, HTC45, HTC54 Series

HTC16/32/45/54 series slant bed CNC lathes are used for the machining of cylindrical, arc, and conic surfaces, grooves and threads in either metric or inch execution, on rotary parts. These machine tools can batch process with high efficiency and accuracy, and are therefore suitable for such industries as automotive, electronic, aerospace, military, etc.

The incorporation of an integral slant bed design ensures that the CNC lathes maintain accuracy while taking heavy cuts. Wide rectangular box-type guideways prevent twisting, bending and lifting of the tool-post. Guideways are laminated with anti- friction material to ensure the optimum positioning accuracy during rapid feeding.

Linear guideways permit high speed movement, minimizing friction resistance and thermal deformation, improving machining accuracy over the longer term.

X and Z axis servomotors are connected to precision ball screws with flexible couplings, maintaining high cutting accuracy.

The design of the spindle also reduces thermal deformation, thus keeping the spindle axis stable over long work cycles.

The horizontal-axis turret incorporates a large disc coupling to fix its position, thus ensuring precise positioning and little deformation due to cutting pressures.

The tool detection device can automatically input the tool-tip position into the CNC, which greatly reduces the adjustment time resulting from a tool change. It can also compensate automatically for tool wear. Our horizontal CNC lathe has fully enclosed workspace, and separate cooling tank and chip conveyor, which prevent the machine from losing accuracy from cutting heat.

| Item | Units | HTC1635 | HTC32 series | HTC45 series | HTC54 series | |

| Max. swing over bed | mm | 400 | 460 | 520 | 630 615(1000/1500) | |

| Max. cutting dia. | mm | 160 | 320 | 450 | 540 | |

| Max. swing over slide | mm | 160 | 260 | 320 | 420 | |

| Max. cutting length | mm | 350 | 550/970 | 540/960/1500 | 650 1000 1500 | |

| Spindle speed | Stepless | Stepless | Stepless | Stepless | ||

| Range of spindle speed | Main servo | High speed bed 60-5000 High rigidity headstock 40-4000 | 35-4000(A2-6) 31.5-3150(A2-8) | 30-3000 | 20-2500 (Main motor a50/6000ip) | |

| Inverter motor | 200-4000 | 200-3000(A2-6) 200-2600(A2-8) | 200-2400 | |||

| Power of main motor (30min/rated) | FANUC 0i-Mate | 11/7.5 | (Frequency conversion)15 | (Frequency conversion)18.5 | ||

| FANUC 0i-TD | 7.5/5.5 | 11/15 | 18.5/15 | 30/22 | ||

| SIEMENS 802D | 12/9 | 30/22 | 30/21.5 | 30/21.5 | ||

| Form and code of spindle nose | A2-5 | A2-6/A2-8 | A2-8 | A2-11 | ||

| Dia. of through spindle bore | mm | 43 | 62/80 | 80 | 85(104) | |

| Hydraulic chuck | 6" | 8"/10" | 10" | 12" | ||

| Form of turret | Horizontal, 8-station | Horizontal, 8-station | Horizontal, 12-station | Horizontal, 8-station | ||

| Size of tool | Tool for turning O.D. | 20×20 | 25×25 | 25×25 | 32×32×170 | |

| Bore | φ20 | φ40/φ32/φ25 | φ40/φ32/φ25 | φ50/φ40/φ32/φ25 | ||

| Indexing time of turret | s | 0.29/0.48 | 0.7/1.8 | 0.7/2 | 0.8/1.5(Power-driven | |

| Repeat positioning accuracy of turret indexing | ±2" | ±2" | ±2" | |||

| Rapid traveling speed of X/Z-axis | Rolling guideway | 12/20 | 12/18 | 12/18 | 12/18 | |

| Sliding guideway | 10/12 | 10/12 | 12/15 | |||

| Travel of X-axis | mm | 110 | 208 | 275 | 325 | |

| Travel of Z-axis | mm | 380 | 600/1020 | 600/1020/1580 | 670/1020/1520 | |

| Dia. /travel of tailstock sleeve | mm | 60/80 | 100/130 | 100/130 | 120/150 | |

| Taper bore of tailstock sleeve | mm | MT4 | MT4 | MT4 | MT5 | |

| Accuracy of workpiece | IT6 | IT6 | IT6 | IT6 | ||

| Surface roughness of workpiece | μm | Ra1.6-0.8 | Ra1.25 | Ra1.25 | Ra1.25 | |

| Max. weighted load (disc/shaft workpiece) | kg | 70/300 | 200/800 | 250/1000 | 200/1000 | |

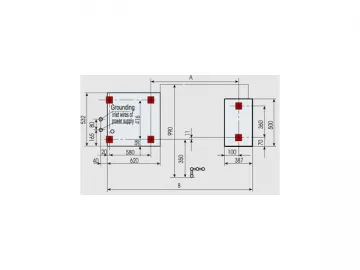

| Machine weight | kg | 3000 | 5500/6000 | 5500/6400/6900 | 7500/8000/8500 | |

Links:https://www.globefindpro.com/products/96305.html

-

Slant Bed CNC Lathe, HTC16

Slant Bed CNC Lathe, HTC16

-

Conventional Lathe CA Series

Conventional Lathe CA Series

-

Horizontal CNC Lathe ETC-h Series

Horizontal CNC Lathe ETC-h Series

-

Slant Bed CNC Lathe, HTC32n

Slant Bed CNC Lathe, HTC32n

-

CNC Milling Boring Machine, GMC Series Gantry Type

CNC Milling Boring Machine, GMC Series Gantry Type

-

Flat Bed CNC Lathe, CAK50/61 Series

Flat Bed CNC Lathe, CAK50/61 Series

-

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

-

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

-

Flat Bed CNC Lathe, CAK16/36/40 Series

Flat Bed CNC Lathe, CAK16/36/40 Series

-

Slant Bed CNC Lathe, HTC1608

Slant Bed CNC Lathe, HTC1608

-

HTC2050n Horizontal-axis CNC Lathe

HTC2050n Horizontal-axis CNC Lathe

-

Slant Bed CNC Lathe, HTC50

Slant Bed CNC Lathe, HTC50