Slant Bed CNC Lathe, HTC16

Slant Bed CNC Lathe, HTC16

This machine integrates electrical mechanical, and hydraulic systems into a compact, space-saving, well laid-out, aesthetically attractive unit, which is easy to maintain.

It is suitable for machining rotary parts of the industries such as automotive, electronic, aerospace, military, etc. and can batch process with high efficiency accuracy.

Features

1. Compact structure, reasonable layout and elegant appearance in design.

2. Fast drive with the merits of time saving, labor saving, energy saving and safe.

3. HTC1612i gang tool design ensures machining accuracy and is a high efficient and environmental friendly device.

| Item Unit | HTC1612i | HTC1635i | ||

| Chuck diameter | inch | 6" | 6" | |

| Max. swing over bed | mm | 450 | 400 | |

| Max. swing over carriage | mm | 160 | 160 | |

| Max. machining diameter | mm | 160 | 160 | |

| Max. cutting length | mm | 120 | 350 | |

| Spindle bore diameter | mm | 48 | 43 | |

| Form of spindle nose | A2-5 | A2-5 | ||

| Max. cutting length of shaft workpieces | mm | 120 | 350 | |

| Max. travel of X axis | mm | 350 | 110 | |

| Max. travel of Z axis | mm | 200 | 380 | |

| Main motor power | kW | 5.5/7.5 | 7.5/11 | |

| Single spindle headstock | Frequency main motor | r/min | - | 200-4000 |

| Servo main motor | r/min | 40-5000 | 40-4000 | |

| Rapid speed (X/Z axis) | m/min | 20/20 | 12/18 | |

| Form of turret | Gang tool | Horizontal 8-position | ||

| Size of tool shank | mm | 20×20 | 20×20 | |

| Diameter of tool hole | mm | φ25 | φ25 | |

| Repositioning accuracy of turret | " | - | ±1" | |

| Workpiece accuracy | IT6 | IT6 | ||

| Positioning accuracy | mm | 0.013/0.016 | 0.013/0.016 | |

| Repositioning accuracy | mm | 0.005/0.006 | 0.005/0.006 | |

| Roughness | μm | Ra1.6 | Ra1.6 | |

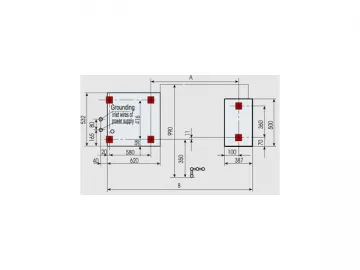

| Overall dimensions of machine (L×W×H) | mm | 1660×1665×1540 | 2300×1430×1725 | |

| Machine weight | kg | 2200 | 3000 | |

| CNC system | GSK980TDb | FANUC or GSK | ||

Scan QR to Read

Links:https://www.globefindpro.com/products/96306.html

Links:https://www.globefindpro.com/products/96306.html

Recommended Products

-

Conventional Lathe CA Series

Conventional Lathe CA Series

-

Horizontal CNC Lathe ETC-h Series

Horizontal CNC Lathe ETC-h Series

-

Slant Bed CNC Lathe, HTC32n

Slant Bed CNC Lathe, HTC32n

-

CNC Milling Boring Machine, GMC Series Gantry Type

CNC Milling Boring Machine, GMC Series Gantry Type

-

Flat Bed CNC Lathe, CAK50/61 Series

Flat Bed CNC Lathe, CAK50/61 Series

-

HMC-c Horizontal Machining Center

HMC-c Horizontal Machining Center

-

Slant Bed CNC Lathe, HTC32, HTC45, HTC54 Series

Slant Bed CNC Lathe, HTC32, HTC45, HTC54 Series

-

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

Vertical Machining Center VMC2180S, VMC21100S, VMC2580S

-

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

Slant Bed CNC Lathe, HTC50t, HTC63t, HTC80t, HTC100t

-

Flat Bed CNC Lathe, CAK16/36/40 Series

Flat Bed CNC Lathe, CAK16/36/40 Series

-

Slant Bed CNC Lathe, HTC1608

Slant Bed CNC Lathe, HTC1608

-

HTC2050n Horizontal-axis CNC Lathe

HTC2050n Horizontal-axis CNC Lathe

Hot Products