Flat Bed CNC Lathe, CAK50/61 Series

CAK 50/61 series CNC lathes are built on established structure, stable inter face, and reliable quality. They are economical, practical, universal type lathes. These lathes are widely used in such industries as automotive, petroleum, military, etc. and are the foremost choice selected by domestic users.

SMTCL CNC lathes can be used for machining inside and outside surfaces of cylindrical and disc-shaped work-pieces, curvilinear surfaces, arc surfaces, threads, bores, etc. They can also be used for machining non-circular curved surfaces, and for reaming. Various CNC systems and accessories are available according to the users' requirements.

CAK50/61 series flat bed CNC lathes adopt horizontal flat beds, hardened guideways, and slides coated with TSF material, for flexible operation and stable accuracy.

Key parts of these lathes are hardened, and structured for good rigidity.

The main drive of the CAK50j flat bed CNC lathe adopts a two-speed motor, with magnetic clutch to realize the speed change. There is a 3-step manual gearbox, each step having 4 speeds in auto mode, for a total of 12 speeds. CAK50i CNC lathes have an AC frequency motor with inverter drive to realize the 3-step auto range change, with step less speed within each step.

Turrets have Hirth style coupling for accurate positioning and repeatability.

The feed system employs servo motors with high accuracy drives to provide better performance.

The flat bed CNC lathe smoothly integrates mechanical, hydraulic, and electrical systems for best machining performance. The modular design easily offers various configurations to meet the customers' needs.

Control systems such as Fanuc, Siemens, SMTCL NC-100, Guangzhou CNC, and Huazong CNC are offered according to the customers' preferences.

Turret options include vertical 4-way, vertical 6-way, and horizontal 6-way toolposts.

J-designation lathes are semi-enclosed, and i-designation lathes are fully enclosed.

Options for chuck include manual, hydraulic, or pneumatic. Tailstock can be either hydraulic or manual.

| Lathe model | CNC system |

| CAK50b(i or j) | SMTCL-NC100 |

| CAK50g(i or j) | SIEMENS 802D |

| CAK50d(i or j) | FANUC 0i Mate |

| CAK50n(i or j) | Guangzhou CNC 980TD |

| CAK50s(i or j) | Huazhong CNC 21T |

| CAK61b(i or j) | SMTCL-NC100 |

| CAK61g(i or j) | SIEMENS 802D |

| CAK61d(i or j) | FANUC 0i Mate |

| CAK61n(i or j) | Guangzhou CNC 980TD |

| CAK61s(i or j) | Huazhong CNC 21T |

Above mentioned CNC lathes can be equipped with other CNC controllers as per user's requirements.

Note: i series machines all adopt full enclosed protection, and i series machines all adopt semi-enclosed protection.

Main Technical Specifications of Flat Bed CNC Lathe

| Item Unit | CAK50i series | CAK50j series | CAK61i series | CAK61j series | ||

| Max. swing over bed | mm | 500 | 500 | 610 | 610 | |

| Span of guideway | mm | 400 | 400 | 400 | 400 | |

| Max. work piece length | mm | 640 890 1390 1900 | 640 890 1390 1900 | 640 890 1390 1900 | 640 890 1390 1900 | |

| Max. cutting length | mm | 600 850 1350 1860 (vertical 4-position ) 520 770 1270 1780 (horizontal 6-position) | 600 850 1350 1860 (vertical 4-position ) 520 770 1270 1780 (horizontal 6-position) | 600 850 1350 1860 (vertical 4-position ) 520 770 1270 1780 (horizontal 6-position) | 600 850 1350 1860 (vertical 4-position ) 520 770 1270 1780 (horizontal 6-position) | |

| Max. cutting dia. | With vertical turret | mm | 500 (vertical 4-position ) 360 (vertical 6-position) | 500 (vertical 4-position ) 360 (vertical 6-position) | 610 (vertical 4-position ) 480 (vertical 6-position) | 610 (vertical 4-position ) 480 (vertical 6-position) |

| Max. swing over slide | mm | 300 | 300 | 370 | 370 | |

| Max. cutting dia. | With horizontal turret | mm | 400 | 400 | 500 | 500 |

| Max. swing over slide | mm | 300 | 300 | 370 | 370 | |

| Spindle nose | A8 | A8 | A8 | A8 | ||

| Chuck | Manual | mm | φ250 | φ250 | φ250 | φ250 |

| Pneumatic | mm | φ250 | φ250 | φ250 | φ250 | |

| Hydraulic | mm | φ250 | φ250 | φ250 | φ250 | |

| Inner taper of spindle nose | 1:20 | 1:20 | 1:20 | 1:20 | ||

| Spindle bore | mm | 70 | 70 | 70 | 70 | |

| Spindle speed | Double - speed motor | n | - | 12 steps | - | 12 steps |

| Variable frequency motor | n | Auto 3-gearshift, stepless | Auto 3-gearshift, stepless | Auto 3-gearshift, stepless | Auto 3-gearshift, stepless | |

| Spindle speed range | Double - speed motor | r/min | - | 40-1800 | - | 40-1800 |

| Variable frequency motor | r/min | 22-220 71-710 215-2200 | 22-220 71-710 215-2200 | 22-220 71-710 215-2200 | 22-220 71-710 215-2200 | |

| Main power | Double - speed motor | kW | - | 6.5/8 | - | 6.5/8 |

| Variable frequency motor | kW | 7.5 | 7.5 | 7.5 | 7.5 | |

| Center height | From bed | mm | 250 | 250 | 305 | 305 |

| From ground | mm | 1130 | 1130 | 1185 | 1185 | |

| Tool post traverse | m/min | 5/10 (6 while Z is 1900mm) | 5/10 (6 while Z is 1900mm) | 5/10 (6 while Z is 1900mm) | 5/10 (6 while Z is 1900mm) | |

| Index time of turret (1 position) | s | 2.4 (vertical 4-position ) 2.2 (vertical 6-position) 1.6 (horizontal 6-position) | 2.4 (vertical 4-position ) 2.2 (vertical 6-position) 1.6 (horizontal 6-position) | 2.4 (vertical 4-position ) 2.2 (vertical 6-position) 1.6 (horizontal 6-position) | 2.4 (vertical 4-position ) 2.2 (vertical 6-position) 1.6 (horizontal 6-position) | |

| Tool post rotative positioning repeatility accuracy | " | 1.5 (2 for horizontal 6-position) | 1.5 (2 for horizontal 6-position) | 1.5 (2 for horizontal 6-position) | 1.5 (2 for horizontal 6-position) | |

| X axis travel | mm | 250 | 250 | 305 | 305 | |

| Z axis travel | mm | 600 850 1350 1860 | 600 850 1350 1860 | 600 850 1350 1860 | 600 850 1350 1860 | |

| Workpiece accuracy | IT6-IT7 | IT6-IT7 | IT6-IT7 | IT6-IT7 | ||

| Surface roughness | μm | Ra1.6 | Ra1.6 | Ra1.6 | Ra1.6 | |

| Dia. of tail stock sleeve/stroke of tailstock sleeve | mm | 75/150 | 75/150 | 75/150 | 75/150 | |

| Bore taper of tailstock sleeve | mm | Morse 5# | Morse 5# | Morse 5# | Morse 5# | |

| Turret form | Vertical 4-position | |||||

| Vertical 6-position | (without tailstock) | (without tailstock) | (without tailstock) | (without tailstock) | ||

| Horizontal 6-position | (without follow rest) | (without follow rest) | (without follow rest) | (without follow rest) | ||

| Size of tool shank | Ex. circle tool | mm | 25×25 | 25×25 | 25×25 | 25×25 |

| Boring tool | mm | φ25 φ32 | φ25 φ32 | φ25 φ32 | φ25 φ32 | |

| Power of general power supply | kW | 15 | 15 | 15 | 15 | |

| Steady rest | mm | φ20-φ125, φ120-φ190, φ140-φ210, φ180-φ250 , 1900 length with steady rest of φ20-φ125 is standard | ||||

| Follow rest | mm | φ20-φ90 , 1900 length is standard | ||||

| Weight of machine (net weight / gross weight) | 640 | kg | 2100/2800 | 2100/2800 | 2200/2900 | 2200/2900 |

| 890 | kg | 2300/3100 | 2300/3100 | 2400/3200 | 2400/3200 | |

| 1390 | kg | 2600/3400 | 2600/3400 | 2700/3500 | 2700/3500 | |

| 1900 | kg | 2900/3800 | 2900/3800 | 3000/3900 | 3000/3900 | |

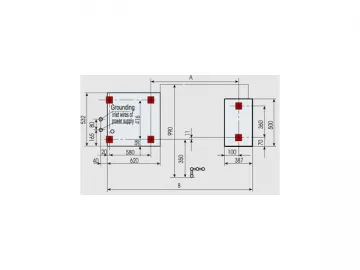

| Packing dimensions (L×W×H) | 640 | mm | 3300×2178×2149 | |||

| 890 | mm | 3550×2178×2149 | ||||

| 1390 | mm | 4050×2178×2149 | ||||

| 1900 | mm | 4550×2178×2149 | ||||

Links:https://www.globefindpro.com/products/96311.html

-

HMC-c Horizontal Machining Center

HMC-c Horizontal Machining Center

-

Slant Bed CNC Lathe, HTC63/80, HTC63b/80b

Slant Bed CNC Lathe, HTC63/80, HTC63b/80b

-

Radial Drilling Machine

Radial Drilling Machine

-

Moving Gantry Turning Milling Center GTM500200

Moving Gantry Turning Milling Center GTM500200

-

HMC-e Horizontal Machining Center

HMC-e Horizontal Machining Center

-

CNC Pipe Threading Lathe STC1135pipe, STC1835pipe

CNC Pipe Threading Lathe STC1135pipe, STC1835pipe

-

CNC Milling Boring Machine, GMC Series Gantry Type

CNC Milling Boring Machine, GMC Series Gantry Type

-

Slant Bed CNC Lathe, HTC32n

Slant Bed CNC Lathe, HTC32n

-

Horizontal CNC Lathe ETC-h Series

Horizontal CNC Lathe ETC-h Series

-

Conventional Lathe CA Series

Conventional Lathe CA Series

-

Slant Bed CNC Lathe, HTC16

Slant Bed CNC Lathe, HTC16

-

Slant Bed CNC Lathe, HTC32, HTC45, HTC54 Series

Slant Bed CNC Lathe, HTC32, HTC45, HTC54 Series