Slant Bed CNC Lathe, HTC63/80, HTC63b/80b

HTC63/80 series CNC lathes are an updated version of the original CK6263 CNC turret lathes which were awarded the National Quality Gold Prize. The machine tools are built on the merits of the original series, and have the additional features of higher power and strong rigidity. They can cut cylindrical, taper, and arc contours, can thread in metric or inch execution, straight, tapered, or multiple-lead threads, with too radius compensation. Our slant bed lathes are therefore suitable for machining shaft-type, disc-type, and sleeve-type workpieces with complex shape, all with high accuracy.

Our CNC lathes with integral slant-bed and 8-position vertical turret are especially designed for machining disc-type work-pieces, and are the first choice for machining this kind of work-piece or for pipe couplings. They have good tool clearance and are suitable for heavy cutting with little tool interference from adjacent stations. This machine is not equipped with a tailstock.

| Item | Units | HTC63 Series | HTC80 Series | HTC6330b | HTC8030b | |

| Chuck diameter | 15" | 15" | φ500 | φ500 | ||

| Max. cutting length | mm | 970 1250 2700 3600 | 970 1250 2700 3600 | 300 | 300 | |

| Max. swing over bed | mm | φ800/φ750/φ710/φ670 | φ1000/φ950/φ910/φ870 | φ790 | φ980 | |

| Max. swing over carriage | mm | φ580 | φ780 | φ550 | φ750 | |

| Max. range of disc workpiece | mm | φ630 | φ800 | φ630 | φ800 | |

| Max. travel of X/Z-axis | mm | 410/1000 1250 410/1300 2700 410/2750 3600 410/3650 | 500/1000 1250 500/1300 2700 500/2750 3600 500/3650 | 420/800 | 515/800 | |

| Spindle bore diameter | mm | 85/100/125(A2-11)85/100/140(A2-15) | 85/100/140 | 85/100/140 | ||

| Range of spindle speed | r/min | 50-1200 | 50-1200 | 50-1200 | 50-1200 | |

| Form of spindle nose | A2-11(A2-15) | A2-11(A2-15) | A2-15 | A2-15 | ||

| Diameter of tailstock sleeve | mm | φ160 | φ160 | - | - | |

| Travel of tailstock sleeve | mm | 120 | 120 | - | - | |

| Taper of tailstock sleeve | Morse | No.5 | No.5 | - | - | |

| Main motor power | kW | 30/37 | 30/37 | 30/37 | 30/37 | |

| Motor torque for X/Z-axis | Nm | 22/30 | 22/30 | 22/30 | 22/30 | |

| Rapid speed (X/Z-axis) | m/min | 10/12 10/12 10/10 10/12 | 10/12 10/12 10/10 10/12 | 8/10 | 8/10 | |

| No. of tool stations | Station | 12 | 12 | 8 | 8 | |

| Size of tool shank | mm | 32×32 | 32×32 | 32×32 | 32×32 | |

| Diameter of tool hole | mm | φ50 | φ50 | φ80 | φ80 | |

| Positioning accuracy of tool turret | arc-second(") | ±6" | ±6" | |||

| Repositioning accuracy of tool turret | arc-second(") | ±2" | ±2" | 0.005 | 0.005 | |

| Workpiece accuracy | IT6 | IT6 | IT6 | IT6 | ||

| Roughness | Ra1.6 | Ra1.6 | Ra1.6 | Ra1.6 | ||

| Positioning accuracy | X-axis | mm | 0.013 0.013 0.013 0.013 | 0.013 0.013 0.013 0.013 | 0.012 | 0.012 |

| Z-axis | mm | 0.020 0.025 0.050 0.060 | 0.020 0.025 0.050 0.060 | 0.02 | 0.02 | |

| Repositioning accuracy | X-axis | mm | 0.007 0.007 0.007 0.007 | 0.007 0.007 0.007 0.007 | 0.007 | 0.007 |

| Z-axis | mm | 0.010 0.013 0.03 0.04 | 0.010 0.013 0.03 0.04 | 0.01 | 0.01 | |

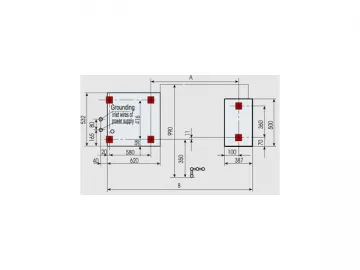

| Overall dimensions of machine (L×W×H) | mm | 4650×2600×2640 5190×2600×2640 6740×2600×2640 7690×2600×2640 | 4650×2600×2640 5190×2600×2640 6740×2600×2640 7690×2600×2640 | 4650×2600×2640 | ||

| Machine weight (net weight) | kg | 14500 16500 22500 26500 | 15000 17000 23000 27000 | 14000 | 14000 | |

Links:https://www.globefindpro.com/products/96314.html

-

Radial Drilling Machine

Radial Drilling Machine

-

Moving Gantry Turning Milling Center GTM500200

Moving Gantry Turning Milling Center GTM500200

-

HMC-e Horizontal Machining Center

HMC-e Horizontal Machining Center

-

CNC Pipe Threading Lathe STC1135pipe, STC1835pipe

CNC Pipe Threading Lathe STC1135pipe, STC1835pipe

-

Vertical Machining Center, VMC1600B, VMC2100B

Vertical Machining Center, VMC1600B, VMC2100B

-

Large CNC Lathe HTC Series

Large CNC Lathe HTC Series

-

HMC-c Horizontal Machining Center

HMC-c Horizontal Machining Center

-

Flat Bed CNC Lathe, CAK50/61 Series

Flat Bed CNC Lathe, CAK50/61 Series

-

CNC Milling Boring Machine, GMC Series Gantry Type

CNC Milling Boring Machine, GMC Series Gantry Type

-

Slant Bed CNC Lathe, HTC32n

Slant Bed CNC Lathe, HTC32n

-

Horizontal CNC Lathe ETC-h Series

Horizontal CNC Lathe ETC-h Series

-

Conventional Lathe CA Series

Conventional Lathe CA Series