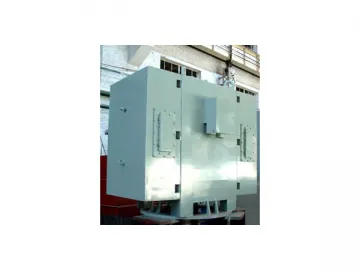

High Voltage High Speed Three Phase Asynchronous Motor

The pedestal of is steel plate welded, which made this high voltage high speed three-phase asynchronousmotor features by high rigidity and light weight. And other upgraded design contributes to the easy installment and maintenance.

Features:

1. The stator and rotor are made of the round cool rolled silicon steel sheet

2. Rotor insulation: F class insulation

3. Rotor bars: arrayed copper, rotary cage: copper or copper alloy

4. Model H355~H450 adopt roll bearings, and grease lubrication. Model H500~H710 adopt slide bearings, and oil lubrication.

Starting of High Voltage High Speed Three Phase Asynchronous Motor:

Generally speaking, series high voltage high speed three-phase asynchronousmotors can be started twice when it stops naturally in cold condition. And under the heat condition, only can be started once. The additional starting must after 1-2 hours after last starting.

And these serieshigh voltage high speed three-phase asynchronous motors can drive various machinery. But if the machinery is water pump or light-load started fanning machine, meanwhile meet the following conditions:

1. The terminal voltage of the motor isn’t less than 85% of rated voltage when start

2. The torque of the fanning machine isn’t more than 35% of the rated torque of motor

3. The moment of inertia of the fanning machine isn’t more than the load value: J in technique data table.

Then the standard cage rotor type three-phase asynchronous motors can be used as the driving motors. And pedestal number and the data in the technique parameter table can be taken directly.

Ordering Requirement:

Any other special requirement such as torque, starting current, height(above 1000m), surrounding temperature( beyond the scope from-15℃ to +40℃), etc please offer the data and sign the relative technique agreement.

Note: if with no special indication, the motor rotate in clockwise and the Outlet box: Right of the motor (see when face the motor shaft), the relative technique data can be provide according the voltage classification.

We are sure, our three-phase asynchronous motors, DC motors, industrial electric motors, etc can service as the ideal drive to improve the working efficiency.

Links:https://www.globefindpro.com/products/96485.html

-

DC Motor

DC Motor

-

Aircraft Hauling Tractor HT-1

Aircraft Hauling Tractor HT-1

-

Blower Ventilated Three Phase Asynchronous Motor (Squirrel Cage Rotor)

Blower Ventilated Three Phase Asynchronous Motor (Squirrel Cage Rotor)

-

Aircraft Hauling Tractor HT-3

Aircraft Hauling Tractor HT-3

-

Industrial DC Motor

Industrial DC Motor

-

High Voltage Three Phase Asynchronous Motor (Wound Rotor)

High Voltage Three Phase Asynchronous Motor (Wound Rotor)

-

DC Motor (Metal Rolling Mill's Drive)

DC Motor (Metal Rolling Mill's Drive)

-

Refuse Compactor

Refuse Compactor

-

Blower Ventilated 3 Phase Asynchronous Motor (Squirrel Cage Rotor)

Blower Ventilated 3 Phase Asynchronous Motor (Squirrel Cage Rotor)

-

Off Line UPS

Off Line UPS

-

Active Power Filter (APF)

Active Power Filter (APF)

-

UPS SNMP Card

UPS SNMP Card