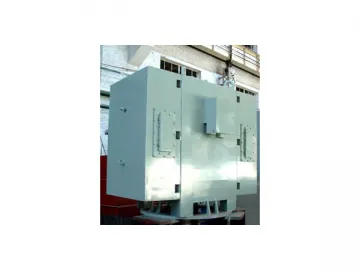

DC Motor

Description of DC Motor Z800-Z1000:

Z800-Z1000 series DC motors are upgraded in the rotor diameter and the electromagnetism load. Meanwhile, these DC motors deliver the required torque while minimizing the inertia of the drive-train. This act make the DC motors quick response to speed and load changes.

Configuration and Features of DC Motor Z800-Z1000:

1. Adopt simplex lap-split throw winding, the equalizer is located in the slot.

2. Excellent commutator and brush holder provide premium commutation

3.With compact size

4. The TIG-welding is applied to connect the commutator risers and armature coils for maximum connection strength.

5. DC motor adopts full compensating structure, Z900, Z1000 adopts radial axial ventilation and the Z800 adopts the axial ventilation.

6. The Pt100 platinum resistance temperature sensor is assembled on the excitation windings, commuter windings, compensating windings, to test the temperature of the wings and bearings.

7. F class VPI (vacuum pressure impregnate) insulation for stator and rotor to withstand moistures, abrasion, and thermal cycling. This make the DC motor can be used in some severe environment.

8. Armature lamination and pedestal feature by paint coating laminated steel frame to improve following ability of electromagnetism, resulting in better commutation.

8. Adopt end bracket type grease ball bearings. The sliding bearings are available.

9. The condensation–resistant heater (220V, 1000W) is equipped in motor

10. For the standard model, the outlet box is located in the right side (see from the rotary side), it also can be designed in the left side.

Performance of DC Motor Z800-Z1000:

1. Power supply can choose direct current or supplied by the stationary rectifier power.

2. The designed motor rating duty: continuous operation based on S1 duty type

3. The standard rated voltage: 220V, 330V, 440V, 550V, 660V, 750V, 850V for choice. The other rated voltage can be adopted on request.

4. The basic excitation type is separated excitation. Four excitation winding terminals are divided into two groups. The excitation voltage is 220V when the two groups are in serials, otherwise, in parallel connection, the voltage become 110V. Other excitation voltage is available. And the forced excitation is allowed while voltage is less than 500V. When adopts the forced excitation, the excitation current is allowed to exceed the rated excitation current slightly until the excitation current goes to stabilization.

5. The mounting arrangement is IM1001 or IM1002, conforming to the standard of GB997 and IEC34-7 in "Code of Motor Construction and Mounting Arrangement". Other mounting arrangements can be designed.

6. The protection class is IP23 or IP4, meet the requirement of GB4942.1 and IEC60034-5in "Rotary motor shell protection classification". Other protection class can be offered.

7.The cooling form is IC06 or IC17 or IC37 or IC86W(ICW37A86)according

to China National Standard GB1993 and IEC Standard 34-6 in "Cooling Form of

Motors". Other cooling form can be designed.

Applications of DC Motor Z800-Z1000:

The high of the center motor can be 800mm, 900mm, 1000mm, so Z800-Z1000 series DC motors are wildly applied in mental rolling mills, mine hoist, ship propulsion, and used as industrial duty motors(in mixers, extruder), or any application requiring high-torque, fast acceleration and low or variable speed

Ordering Requirement for DC Motor:

1. On the none-driving side, these industrial DC motor can be assembled with tachogenerator, rotary coder, centrifugal switch, temperature sensor(for stator and bearing), heating component, motor pedestal, water cooler, and more. If need these components, please contact us when order and state in the contract.

2. Before order, please check the samples to decide the needed model and specifications. If the models you will order are at variance with the sample, please contact us immediately.

3. When ordering, please specify the following item: model, classification, power, voltage, rotary speed, excitation voltage, duty type, mounting arrangement, cooling method, protection class, cable outlet direction, spare pares(if need)

Harbin Electric Machinery Co,. Ltd. is an industrial electric motor manufacturer, providing DC motors, Three Phase asynchronous motors, synchronous frequency converters, synchronous motors, etc.

Links:https://www.globefindpro.com/products/96486.html

-

Aircraft Hauling Tractor HT-1

Aircraft Hauling Tractor HT-1

-

Blower Ventilated Three Phase Asynchronous Motor (Squirrel Cage Rotor)

Blower Ventilated Three Phase Asynchronous Motor (Squirrel Cage Rotor)

-

Aircraft Hauling Tractor HT-3

Aircraft Hauling Tractor HT-3

-

Industrial DC Motor

Industrial DC Motor

-

High Voltage Three Phase Asynchronous Motor (Wound Rotor)

High Voltage Three Phase Asynchronous Motor (Wound Rotor)

-

DC Motor (Metallurgic Crane's Drive)

DC Motor (Metallurgic Crane's Drive)

-

High Voltage High Speed Three Phase Asynchronous Motor

High Voltage High Speed Three Phase Asynchronous Motor

-

DC Motor (Metal Rolling Mill's Drive)

DC Motor (Metal Rolling Mill's Drive)

-

Refuse Compactor

Refuse Compactor

-

Blower Ventilated 3 Phase Asynchronous Motor (Squirrel Cage Rotor)

Blower Ventilated 3 Phase Asynchronous Motor (Squirrel Cage Rotor)

-

Off Line UPS

Off Line UPS

-

Active Power Filter (APF)

Active Power Filter (APF)