Frequency Converting Speed-adjustable Synchronous Motor

Configuration of Synchronous Motor:

I. Stator

1. Stator frame: integral, high strength, high rigidity

2. Stator core: made of cool rolled silicon steel plate

3. Stator coil: Double lap windings with two or three lines copper coil, F class insulation due to covered by epoxy resin bonded glass-backed mica paper tape

4. Stator leads cable: designed according to the connection way of the frequency converter, the number of the cable decided by the user. There are 9 Pt100 platinum resistance temperature sensors to test the temperature of the stator coil and stator core

5. Take peak voltage and du/dt into account, with the series insulation system under 6600V, 3300V, 1650V, 690V for the AC-DC frequency converter and AC-AC frequency converter

6 Stator terminal: fixed strongly on the axial and radial direction.

7. VPI (vacuum pressure impregnate) insulation.

II.Rotor (Salient pole)

1. The main axial: made of the high rigidity wrought steel

2. Pole piece: made of 1.5mm cool rolled steel plate

3. Pole coil: common type or heat sink type for choices

4. Slip ring: sleeve type or fabricated structure

5. Damping winding: full damping system

6. Pole coil insulation: adopt high strength nomex paper

III. Bearing, lubrication and oil supply

1. Breaking stand: steel plate welded,

2. Bearing shell: made of cast steel and hydrogen removing treatment

3. Resistance thermometer is equipped on the bearing, to control of the running temperature

4. The insulated bearing is used as the non-driven-end bearing to avoid the axial current

5. The earthed carbon brush is designed on the driven-end bearing

6. Adopt low pressure to supply the bearing oil in high reliability and low friction damage.

IV. Excellent shell and air-cooling system

Temperature monitor: done by the Pt100 resistance temperature sensor

Features of Synchronous Motor:

1. High efficiency, energy saving: optimized design reduce the life cycle cost

2. Improved the damp function for quick response property, convenient to adjust rotary speed

3.Applicable to multiple voltage types and drive devices

4. Multiple cooling forms: side water cooling, top water cooling, bottom water cooling, pipe air cooling, etc.

5. High reliability and maintenance

Parameters ofSynchronous Motor:

Application ofSynchronous Motor:

welcome to visit the website, welcome to choose HEC DC motors , industrial electric motors, synchronous motors, frequency converters, etc.

Links:https://www.globefindpro.com/products/96506.html

-

DC Motor (Reversing Mill's Drive)

DC Motor (Reversing Mill's Drive)

-

Self Tipping Semi-Trailer

Self Tipping Semi-Trailer

-

Front Tipping Dump Truck

Front Tipping Dump Truck

-

Resin for Surface Layer

Resin for Surface Layer

-

Moisture Curing Polyurethane Resin

Moisture Curing Polyurethane Resin

-

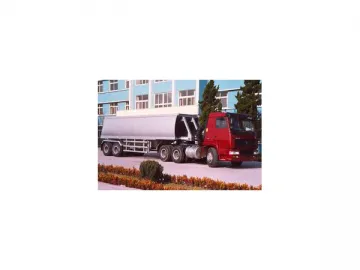

Bottom Tipping Semi-trailer

Bottom Tipping Semi-trailer

-

Side Loading Garbage Truck

Side Loading Garbage Truck

-

Aircraft Hauling Tractor HT-2

Aircraft Hauling Tractor HT-2

-

DC Motor (Metallurgic Crane's Drive)

DC Motor (Metallurgic Crane's Drive)

-

High Voltage Three Phase Asynchronous Motor (Wound Rotor)

High Voltage Three Phase Asynchronous Motor (Wound Rotor)

-

Industrial DC Motor

Industrial DC Motor

-

Aircraft Hauling Tractor HT-3

Aircraft Hauling Tractor HT-3