Mineral Processing Jig

Mineral Processing Jig

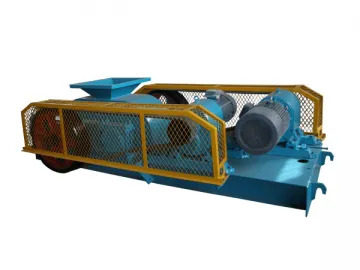

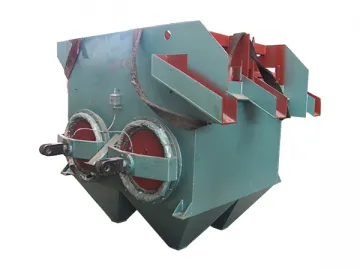

The mineral processing jig, a kind ofgravity beneficiation equipment, separates minerals based on specific gravity.Due to large processing capacity, wide applicable particle size range, andsimple operation and maintenance, our mineral processing jig is widely used forseparating gold, tin, titanium, iron, coal and other minerals, especiallymanganese ore.

Diaphragm jig is a piece of commonly used mineral processing equipment inmetallic ores separation, and it can be divided into different types accordingto the diaphragm position. According to the particle size of raw materials, amineral processing jig can be classified into the ones for separation of coarseand fine materials. The chamber is available in rectangular, trapezoid andround shapes.

Technical Parameters of MineralProcessing Jig

| Name | Chamber number | Chamber area ( m³ ) | Feeding Size (mm) | Capacity (t/h) | Stroke ( mm ) | Motor | Weight (kg) | |

| Model | Power (KW) | |||||||

| 100×150 diaphragm jig | 1 | 0.015 | ≤ 3 | 0.018-0.6 | - | Y80L-4 | 0.55 | 130 |

| 300×450 diaphragm jig with double chambers | 2 | 0.27 | ≤ 12 | 3-6 | 0-26 | Y90S-4 | 1.1 | 745 |

| 1000×1000 cone diaphragm jig (bottom acting type) | 3 | 2 | 1-5 | 10-25 | 0-26 | Y100L-6 | 1.5 | 1700 |

| 370×360 cone diaphragm jig (bottom acting type) | 2 | 0.274 | ≤ 6 | 6 | 5-25 | Y90SL2-4 | 1.1 | 240 |

| Trapezoid, side acting type diaphragm jig | 3 | 2.7 | ≤ 3 | 12.5-37.5 | 13-21 | Y90SL3-4 | 1.1 | 2000 |

| 670×920 jig | 2 | 1.44 | 4-8 | 7-10 | 18-24 | - | - | - |

Abovetechnical specifications regarding our different types of mineral processingjigs are subject to change without prior notice.

Lipu is a professional mineral processing jigmanufacturer in China.Apart from mineral processing equipment, we also offer industrial grindingequipment, stone crushing machine, drying equipment, and screening equipment,among others.

Links:https://www.globefindpro.com/products/97006.html