Solar Frame Crimping Machine

Solar Frame Crimping Machine

Model: TCZK02

This solar frame crimping machine isdesigned to assemble an aluminum frame by pressing four aluminum profiles with45 degrees ends together. It is commonly used for solar module’s frame assembly.

1. Pneumatic corner combination

Our solar frame crimping machine can assemble an aluminium solar panelframe by using pneumatic corner combination method. With high pneumatic force,it can ensure tightly corner combination, and the corner-combination gap isusually smaller than 0.2mm.

Processes

Firstly glue the aluminium profiles that going to be used for solar moduleframe formation, and then put the solar cells and related assemblies orderly inthe aluminium framework. Thus, the solar frame crimping machine can combine theprofiles together to form a frame by giving pneumatic forces on the fourcorners synchronously.

2. Hydraulic corner combination

Our solar panel frame crimping machine can also use hydraulic method forframe assembly, and the maximum corner-combination gap is controlled within0.2mm. After aluminum frame gluing and solar panel assemblies, etc. arepositioned, the solar frame crimping machine will then finish corner rivetingcombination using hydraulic force.

Efficiency

2 frames/minute

For users’ convenience, we include 35# and 50# aluminiumprofile stamping dies with the shipment of the solar frame crimping machine.

Technical Specifications of Solar FrameCrimping Machine

| Max. frame size | 1100 mm ×2100mm |

| Min. frame size | 500mm ×500mm |

| Frame-assembly method | Pneumatic |

| Working air pressure | 0.4Mpa-0.7Mpa |

| Max. equipment size | 3000mm ×1800 mm ×1000 mm |

| Frame-assembly precision | Opposite side size precision ±1mm |

| Diagonal line size precision | ±1mm |

| Angular deviation among the four corners | ±0.5 ° |

| Working voltage | 220V |

| Weight | 1000kg |

We are a professional solar frame crimping machine manufacturer based in China. We offeran extensive line of products, including aluminum cutting machine, aluminumcorner combining machine, aluminum profile processing equipment, woodprocessing center, and much more.

Links:https://www.globefindpro.com/products/97134.html

-

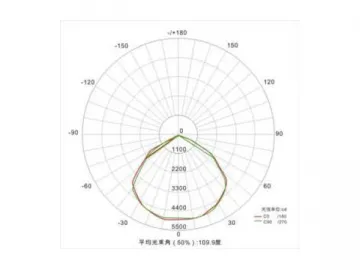

80W LED Tunnel Light

80W LED Tunnel Light

-

80W LED Industrial Light

80W LED Industrial Light

-

30W LED Floodlight

30W LED Floodlight

-

Automatic Solar Module Laminating Machine

Automatic Solar Module Laminating Machine

-

30W LED Industrial Light

30W LED Industrial Light

-

Double-Head Aluminum Solar Frame Cutting Machine

Double-Head Aluminum Solar Frame Cutting Machine

-

LED Light Driver, LED Power Supply

LED Light Driver, LED Power Supply

-

80W/100W LED Street Light RD690

80W/100W LED Street Light RD690

-

200W LED Tunnel Light

200W LED Tunnel Light

-

Semi-Automatic Solar Module Laminator

Semi-Automatic Solar Module Laminator

-

100W Industrial LED Light

100W Industrial LED Light

-

60W LED Floodlight

60W LED Floodlight