High Speed 3-Axis CNC Processing Center

High Speed 3-Axis CNC ProcessingCenter

Model: GCGZC-CNC-7000

1. Our high speed 3-axis CNCprocessing center is ideal for processing the installation holes, guttergrooves and lockholes on aluminum alloy profiles,industrial aluminum products, non-ferrous metal workpiecesand light section steel structures.

2. A complete set of servo control system and Germany Lenzespindle motor help ensure reliable equipment performance.

3. By once material clamping, the CNC processing center can finish hole-drilling,milling, and thread tapping steps at a stroke.

4. The body of the CNC processing equipment is welded using high quality steeltubes and undergoes heat treatment. This guarantees high equipment structurestability and superior rigidity.

5. Taiwanturret-style 14-position tool magazine keeps fast tool change.

6. With dualmaterial-positioning system, the high speed 3-axis CNC processing center canfeed materials successively without machine stop, so as to achieve continuousworking and ensure high efficiency.

7. With machine head position detecting and operator position detectingsystems, the CNC processing machine can ensure operator safety.

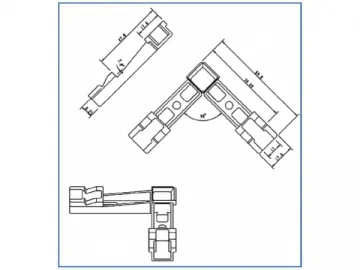

8. A lock knife block is available to make tool changing convenient.

Technical Specifications of High Speed 3-AxisCNC Processing Center

| X axis travel | 7200mm |

| Y axis travel | 400mm |

| Z axis travel | 400mm |

| X axis speed | 0~60m/min |

| Y axis speed | 0~30m/min |

| Z axis speed | 0~30m/min |

| Spindle power | 6.9KW |

| Spindle speed | 0 ~10000rpm |

| Machine tool dimension (L×W×H) | 10000 ×2300 ×2800 |

| Working voltage, frequency | 380V 50HZ |

| Total power | 15KW |

As a specialized high speed 3-axis CNC processing center manufacturer in China,we also provide high speed 4-axis CNC processing center, CNC processing center,double-head CNC aluminum cutting machine, wood processing center, and fourmiter CNC corner crimping machine, among others.

Links:https://www.globefindpro.com/products/97181.html

-

Wooden Window Frame Combination Machine

Wooden Window Frame Combination Machine

-

Precision Double-Head CNC Aluminum Cutting Machine

Precision Double-Head CNC Aluminum Cutting Machine

-

CNC Processing Center

CNC Processing Center

-

Battery Cable YE-12

Battery Cable YE-12

-

Battery Cable YE-4

Battery Cable YE-4

-

Double Head Copy-Routing Aluminum Milling Machine

Double Head Copy-Routing Aluminum Milling Machine

-

Aluminum Profile Milling Machine

Aluminum Profile Milling Machine

-

Woodworking Dust Collector

Woodworking Dust Collector

-

Aluminum Profile Tenon Milling Machine

Aluminum Profile Tenon Milling Machine

-

Single Spindle Copy Router

Single Spindle Copy Router

-

Wooden Window Angle Combination Machine

Wooden Window Angle Combination Machine

-

Wooden Window Tenon Drilling Machine

Wooden Window Tenon Drilling Machine