Multi Spindle Copy Router

Multi Spindle Copy Router

Model: LXF2Ⅱ-1900×125

1. Our multi-spindle copy router is designed for machining the holes and grooves on aluminum door, window and curtain wall extrusions.

2. The aluminum profile clamping and electrical motor starting are both pneumatically controlled, which ensures safe and reliable performance.

3. Equipped with high power variable frequency electrical spindles, the multi-spindle copy router can be used for a wide range of applications, and can also achieve continuous copy machining, which ensures high working efficiency and safe and simple operation.

4. This multi-spindle copy router comes with a horizontal travelling and a vertical travelling machine heads, which allows for both vertical and horizontal direction machining with once profile clamping.

Technical Specifications of Multi Spindle Copy Router

Working pressure | 0.5 ~ 0.8Mpa |

Air consumption | 20L /min |

Input power | 2.2Kw |

Input voltage | 380V/220V 50Hz |

Variable frequency electrical spindle speed | 0-12000r/min |

Copy machining range | 1900 ×125 |

Machining roughness | Ra12.5 μm |

Cutter diameter | φ5, φ8 |

Machining material sectional area | Upper surface: W230 ×H150 ~ 210 Side surface: W230 ×H135 |

Equipment dimension | 3300 ×1400 ×1700mm (both saw gauges are included) |

As an experienced multi spindle copy router manufacturer and supplier in China, Jinan Tianchen also offers single spindle copy router, high speed 4-axis CNC processing center, solar PV module equipment, double-head CNC aluminum cutting machine, wood processing center, and many others.

Links:https://www.globefindpro.com/products/97215.html

-

Corner Crimping Machine

Corner Crimping Machine

-

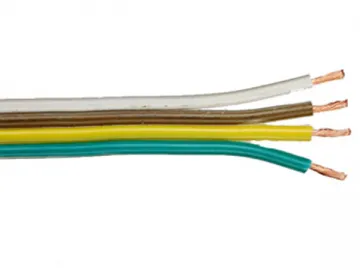

Composite Cable TE-2

Composite Cable TE-2

-

Coaxial Cable LE-4

Coaxial Cable LE-4

-

Speaker Cable SC-2

Speaker Cable SC-2

-

Audio Cable CA-10

Audio Cable CA-10

-

Coaxial Cable LE-1

Coaxial Cable LE-1

-

Four Position Soldering Worktable

Four Position Soldering Worktable

-

Automatic Aluminum Door Window End Milling Machine

Automatic Aluminum Door Window End Milling Machine

-

Double Miter CNC Corner Crimping Machine

Double Miter CNC Corner Crimping Machine

-

Diode Laser Scribing Machine

Diode Laser Scribing Machine

-

Heavy Duty Aluminum Door Window End Milling Machine

Heavy Duty Aluminum Door Window End Milling Machine

-

Battery Cable YE-9

Battery Cable YE-9