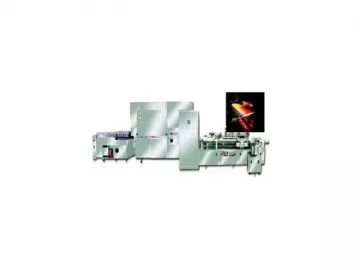

Ampoule Linked Production Line

Ampoule Linked Production Line

Model: ALX-A

Main Applications

The production line, which consists of a ampoule wahing machine, sterilizing dryer and ampoule filling and sealing machine, is used in the production of ampoule. It is fit for alternate water and air spray washing of the B type easily broken retort ampoule, hot air laminar drying and sterilizing, and multi-needle filling and sealing.

Features of Ampoule Linked Production Line

The whole ampoule machine is under PLC control, and can be operated with single machine.

The working state of each position, which is displayed by light pole or by man-machine interface, is automatically supervised.

In the clear room, detector can be mounted for site supervision.

With PC automatic checking function, the machine stops automatically in case of failure, and the failure position and trouble shooting can be displayed for easy repair.

The vertical ultrasonic wave washing machine is equipped with over-load protection device for safety.

The sterilization dryer adopts surface cooler technology, realizing no-suction wind and zero discharge.

The filling machine uses step type table for easy washing, with optional peristaltic pump, glass pump and ceramic pistion pump for option.

Visual talking device can be provided according to custemer's requirement.

The application of the servo motor driving, PLC, frequency converting speed regulation makes the control system of this ampoule production line reach the world advanced level.

Technical Specifications of Ampoule Linked Production Line

Model No. | ALX-A ampoule linked production line | ||

Type of unit | KCQ40 ampoule ultrasonic wave cleaning machine SZAL400/32 tunnel sterilization dryer AGS8 ampoule filling and sealing machine | KCQ60 ampoule ultrasonic wave cleaning machine ASMR600/43 tunnel sterilization dryer AGS8 ampoule filling and sealing machine | KCQ80 ampoule ultrasonic wave cleaning machine ASMR600/43 tunnel sterilization dryer AGS10 ampoule filling and sealing machine |

Applicable specification | 1ml 2ml 5ml 10ml 20ml ampoule | 1ml 2ml 5ml 10ml 20ml ampoule | 1ml 2ml 5ml ampoule |

Filling precision | Conforming to 《Pharmacopoeia of the People's Republic of China》 | ||

Filling pump precision | ≤±2% | ||

Qualified product rate | ≥99% | ||

Distiller Water | 0.25Mpa 50℃ 0.3m3h | 0.25Mpa 50℃ 0.45m3/h | 0.25Mpa 50℃ 0.6m3/h |

Compressed Air | 0.25Mpa ≈30m3/h | 0.25Mpa ≈45m3/h | 0.25Mpa ≈60m3/h |

Power | 49.44 kw | 60.24 kw | |

Vacuum | Suction rate 17m3 Extreme vacuum 150mbar | ||

Number of operators | 3 | ||

Outline Dimension | 8920×2295×2350(mm) | 8920×2345×2350(mm) | |

Weight | ~6300kg | ~6400kg | |

Ultrasonic Wave Washing Machine

Model: KCQ80(60)(40)

Main Applications

Our ultrasonic wave washing machine is ideally suited for automatic washing of various kinds of ampoules. Specifically, it is mainly used for the washing of 1ml, 2ml, 5ml, 10ml and 20ml ampoules.

Features of Ultrasonic Wave Washing Machine

This machine, which is of vertical rotation structure, uses mechanic hand to clamp and overturn the bottle, and washes the bottles by ultrasonic washing and water-air alternation spray.

It employs an overload protection device, making it stop immediately when the main shaft is overloaded.

On the washing control cabinet, there are filling machine's working state feedback light and visual talking or man-machine interface display and control, enabling the operator to know the clean room internal working state at any time.

The washing process is automatically controlled according to the working states of the filling machine and the dryer.

Technical Specifications of Ultrasonic Wave Washing Machine

Model No. | KCQ40 | KCQ60 | KCQ80 |

Applicable sizes | 1ml 2ml 5ml 10ml 20ml | 1ml 2ml 5ml 10ml 20 ml | 1ml 2ml 5ml 10ml 20ml |

Power | 10.54kw | ||

Water consumption | 0.25Mpa 50℃ 0.3m3/h | 0.25Mpa 50℃ 0.45m3/h | 0.25Mpa 50℃ 0.6m3/h |

Air consumption | 0.25Mpa 30m3/h | 0.25Mpa 45m3/h | 0.25Mpa 60m3/h |

Outline dimension | 2170×2230×1400(mm) | ||

Weight | 1900kg | ||

Ampoule Tunnel Sterilization Dryer

Main Applications

Our ampoule tunnel sterilization dryer is mainly used on the injection linked production line of pharmaceutical factories. It is suitable for continous drying, sterilizing and pyrogen removing of the washed ampoule or big/small glass medicine bottle.

Features

Using heating of “hot air laminar flow”, it achieves constant and even heating

Short sterilization time, good sterilization effect

High production capacity

Ampoule Filling and Sealing Machine

Model: AKGFS8

Main Applications

AKGFS8 is a new type dual-purpose machine designed for ampoule filling and sealing. It is mainly applicable to 8-needle filling and sealing of 1ml~20ml ampoule and 10-needle filling and sealing of 1ml~5ml ampoule. And antibiotic bottle medicine liquid filling, stopper adding and semi stopper adding are mainly applicable for 2ml~15ml, 8-needle filling.

Brief Introduction

The kind of pharmacy equipment mainly consists of transmission part, bottle inlet part, filling part, stopper adding part, bottle outlet part and hopper framer. Optional peristaltic pump, glass pump and ceramic pision pump are available for you to choose. This machine can be either for single machine production, or for linked production line.

Features of Ampoule Filling and Sealing Machine

You can change the production of antibiotic bottle to ampoule by changing a few parts, or vice versa.

Compact and simple structure for easy maintenance

Step type table of the filling machine for convenient washing

Servo motor driving, PLC, frequency converting speed regulation

The bottle inlet system has mesh-belt transition, rotary plate and screw rod structure.

Direct bottle inlet reduces bottle contamination

The bottle inlet speed can be efficiently controlled for front-rear synchronization.

Reduced screw rod's friction, increased bottle inlet efficiency

Links:https://www.globefindpro.com/products/97344.html

-

Soft Tube Filling Sealing Machine

Soft Tube Filling Sealing Machine

-

Rotary Tablet Press ZPW

Rotary Tablet Press ZPW

-

Labeling Machine

Labeling Machine

-

Intelligent Packaging Machine

Intelligent Packaging Machine

-

Bactericidal Drying Machine

Bactericidal Drying Machine

-

Horizontal Packing Machine

Horizontal Packing Machine

-

Rotary Tablet Press (Flower Basket)

Rotary Tablet Press (Flower Basket)

-

Rotary Tablet Press ZP100

Rotary Tablet Press ZP100

-

High Speed Granulator

High Speed Granulator

-

Centrifugal Spray Dryer

Centrifugal Spray Dryer

-

Rotary Tablet Press ZP37

Rotary Tablet Press ZP37

-

Swing Granulator

Swing Granulator