ASB4 Automatic Pouch/Bag Making Machine (Three Servo)

ASB4 Automatic Pouch/Bag Making Machine(Three Servo)

Description of Automatic Pouch/Bag Making Machine (Three Servo):

This high speed pouch/bag making machine is specialized in producing three sidesealing pouch/bag and stand up pouch (the bottom is inserted by separatelayer), as well as three side sealing pouch with zipper and stand up pouch withzipper, whose material is with laminated plastic film such as BOPP/PE, PET/PE,Nylon/PE, BOPP/AL/PE, Paper/PE,BOPP/CPP,PET/CPP, Nylon/CPP,BOPP/AL/CPP etc. Withhigh standard and quality, this machine is widely used in making solid andliquid pouch and bags for food package area and other industrial package field.It is equipped with double servo, controlled by PLC and operated through thetouching display screen. And we have received the “CE” certificate as for thismachine.

A. Technical Parameters of Automatic Pouch/Bag Making Machine (Three Servo):

| Items | Description | |

| Material width | 1200mm | |

| Material diameter | 600mm | |

| Bag type | 3 side sealing bag | Bag length: 50-550mm Bag width: 60-600mm Bag-making speed: 35-160pcs/min Feeding speed: 35m/min |

| 3 side sealing bag with zipper | 2 lanes: Max. 300x250 mm (l x w) 1 lane: Max. 560x250 mm (l x w) Zipper bag-making speed 35-120 cut/min (one lane)) Position of zipper: 25mm | |

| Stand up bag with zipper | 2 lanes Max. 270x 250 mm (l x w) 1 lane: Max. 540x 250 mm (l x w) Speed of making zipper bag: 35-120 cut/min (one lane) | |

| Stand up bag | Bag width: 60-250mm Bag length: 120-270mm (two lanes), 540mm (one lane) Speed: 35-120 cut/min (one lane)) Size of bottom folding depth: Max. 70mm Diameter of pouching hole: 12-15mm | |

| Sides sealing bag | Width 500mm Length 300mm (Once feeding) | |

| Total power | 52 kw | |

| Overall dimension | 11350x2100x1860mm | |

| Weight: | 5200 kg | |

B. Main Structure of Automatic Pouch/BagMaking Machine (Three Servos):

| Items | Description | |

| Chief motor (sew) | 3000w | |

| Servo motor driving | 3 sets (1-1.5kw) | |

| Main unwinding motor | 250w | |

| Main motor (Panasonic frequency conversion) | 3000w | |

| Main unwinding (Panasonic frequency conversion) | 400w | |

| Unwinding motor for stand up pouch | 2 sets (180 w) | |

| Unwinding for stand up pouch | 2 sets (400w) | |

| Auto tension controller | "Mitsubishi "magnetic powder brake & rotary coder | |

| EPC for unwinding film | by double photocell | |

| Temperature controller (pc) | 22 sets | |

| Heating of crossing direction sealing | 4 sets | |

| Cooling of crossing direction sealing | 1 set | |

| Heating of machine direction sealing | 4 sets | |

| Cooling of machine direction sealing | 4 sets | |

| Zipper heating | 2 sets | |

| Zipper cooling | 2 sets | |

| Punching device | 4 sets | |

| Waste film winder | 2 units | |

| Electric control | "Panasonic" PLC with 10.4 “colorful touching screen | |

| Accessories of zipper device | Rack of zipper device | 1 set |

| Zipper heating: (2000w x 4 =8000w) | 2 sets | |

| Zipper cooling | 2 sets | |

| Guide of inserting zipper | 2 sets | |

| Zipper heating plate | 2 sets | |

| Zipper spot heating | 4 pcs | |

| Zipper spot heating plate | 2 pcs | |

| Cross rack of zipper heating (adjustable) | 2 sets | |

| Cushion of zipper heating | 2 pcs | |

| Zipper heating blade | 4 pcs | |

| Accessories of stand up bag device | Rack of stand up bag | 1 set |

| Double-swing rod | 1 set | |

| Bottom film unwinding device | 2 sets | |

| Folding device | 2 sets | |

| Quide plate | 2 sets | |

| Cross heating and spot heating: | 2 pcs/each | |

| “R” type heating blade: | 4 pcs | |

| Punch device of bottom folding | 2 sets | |

C. Standard Accessories of AutomaticPouch/Bag Making Machine (Three Servos):

| Items | Description |

| Up and down blade | 1 set |

| Synchronous belt | 2 pcs |

| Magnetic valve | 2 pcs |

| Pressure-reduce valve | 2 pcs |

| Thermocouple | 2pcs |

| Fuse | 5pcs |

| Temperature control meter | 1 pc |

| Approaching switch | 1 pc |

| Tool | 1 set |

| Heating knife (30mm,40mm,50mmx640mm) | 3 sets |

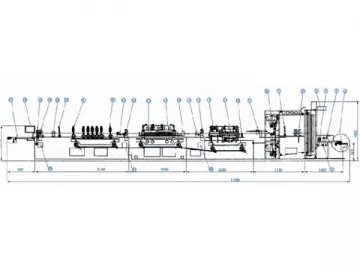

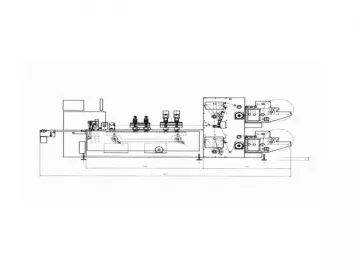

1. Main web

2. Coder

3. Tension toll

4. Rewind roll

5. E.P.C

6. Folding tape unit

7. Bottom tape punching unit

8. Dual dancing roll

9. Photo eye sensor

10. Zipper sealing unit

11. Zipper sealing unit

12. Zipper sealing unit

13. Feeding roll

14. Compensate roll tension

15. Photo eye sensor

16. Longitudinal sealing unit

17. Longitudinal cooling unit

18. Feeding roll

19. Compensate roll for tension

20. Cross sealing unit

21. Cross cooling unit

22. Punching unit

23. Photo eye sensor

24. Feeding roll

25. Electric control unit

26. Conveyor

27.Servo motor for feeding

28. Servo motor for feeding

29. Servo motor for feeding

High quality bag making machine, rotogravure printing machine are available.

Links:https://www.globefindpro.com/products/97573.html

-

Pharmaceutical Asepsis Pouch Making Machine (Double Servo)

Pharmaceutical Asepsis Pouch Making Machine (Double Servo)

-

Side Sealing and Cutting Bag Making Machine

Side Sealing and Cutting Bag Making Machine

-

Cylinder Head

Cylinder Head

-

Starters

Starters

-

Engine Maintenance Equipment

Engine Maintenance Equipment

-

Connecting Rods, Fuel System, Piston, Camshaft

Connecting Rods, Fuel System, Piston, Camshaft

-

Linear Kits

Linear Kits

-

Steering Pump

Steering Pump

-

ABS19 Automatic Double Folding Machine

ABS19 Automatic Double Folding Machine

-

Heating Block

Heating Block

-

Electronic Watt-hour Meter

Electronic Watt-hour Meter

-

Automatic Liquid Filling Line (Straight Type)

Automatic Liquid Filling Line (Straight Type)