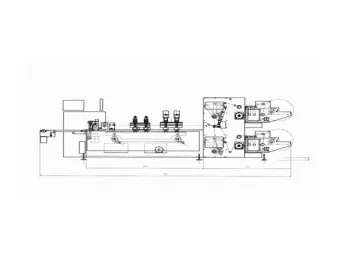

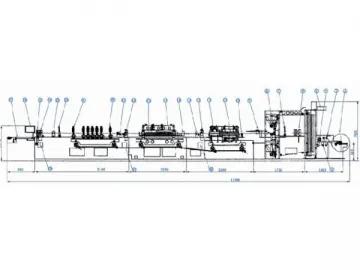

Pharmaceutical Asepsis Pouch Making Machine (Double Servo)

Pharmaceutical Asepsis Pouch MakingMachine (Double Servo)

Description of Pharmaceutical Asepsis Pouch Making Machine (Double Servo):

Equipped with double servo, PLC controller and the touching display screenoperation system, this pouch-making machine can produce pouches with three sidesealing type and tube in roll. It is widely used in making pharmaceuticalpouches for packing medical instrument, and is suitable to use the film-coatedpaper. And also we have received the “CE” certificate as for this machine.

Technical Parameters of Pharmaceutical Asepsis Pouch Making Machine (DoubleServo):

| Items | Description |

| Pouch-making size | 600mm(width)X 440mm(length) |

| Width of unwinding(double unwinding) | 600mm |

| Hot sealing mould plate | 640mm X 400mm (7000-9000W) |

| Cooling mould plate | 640mm X 400mm |

| Working speed | 20-140pcs/min |

| Main motor power | 4-5KW |

| Servo reducer | VGM |

| Driving servo | 1.5KW |

| Temperature | 0-250℃ |

| Mould cylinder | ¢100 X 45 (4 sets, air=0.6Mpa / power=4000N X 4) |

| Main transmission with deflective structure | |

| Main unwinding motor | 250W & 500W (2 sets, local brand) |

| Main unwinding inverter | 750W (2 sets, Panasonic) |

| Magnetic tension control of unwinding & encoder | 1 set, Mitsubishi |

| EPC for unwinding | 1 set (automatic) |

| Air shaft for unwinding | ¢75mm X 2pcs |

| Driving servo | 1000W & 1500W (2 sets) |

| Photocell | 1 set, Weilun |

| Photocell for EPC | 2 sets, Futai |

| Temperature controller (PC) | 8 sets |

| Cross punching device | 1 set |

| Waste film re-winder | 1 unit |

| PLC control the machine | |

| Total power | 25KW |

| Overall dimension | 6500 X 3300 X 1300(mm) |

| Steam sprayer device | optional |

Links:https://www.globefindpro.com/products/97574.html

-

Side Sealing and Cutting Bag Making Machine

Side Sealing and Cutting Bag Making Machine

-

Cylinder Head

Cylinder Head

-

Starters

Starters

-

Engine Maintenance Equipment

Engine Maintenance Equipment

-

Connecting Rods, Fuel System, Piston, Camshaft

Connecting Rods, Fuel System, Piston, Camshaft

-

ASB5 Automatic Pouch Making Machine

ASB5 Automatic Pouch Making Machine

-

ASB4 Automatic Pouch/Bag Making Machine (Three Servo)

ASB4 Automatic Pouch/Bag Making Machine (Three Servo)

-

Linear Kits

Linear Kits

-

Steering Pump

Steering Pump

-

ABS19 Automatic Double Folding Machine

ABS19 Automatic Double Folding Machine

-

Heating Block

Heating Block

-

Electronic Watt-hour Meter

Electronic Watt-hour Meter