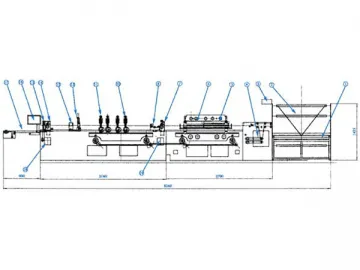

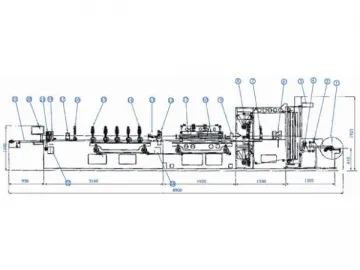

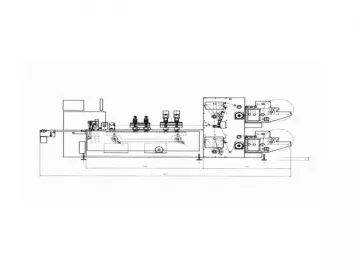

ASB5 Automatic Pouch Making Machine

ASB5 Automatic Pouch Making Machine

Usage of Automatic Pouch Making Machine :

This kind Automatic Pouch making Machine is widely used in making centersealing pouch and center sealing pouch with gusset and three side sealingpouches with different kinds of composite plastic membrane. The key point liesin that it is low-cost and very suitable for those small-middle packagingfactory to invest at the very beginning.

A. Technical Parameters of Automatic Pouch Making Machine :

| Items | Description |

| Size of un-winder | Max. width: 850mm Diameter: 600mm |

| Speed of feeding material | Max: 28 m/min |

| Production capacity | Three side sealing: 100 cuts/min Center sealing: 90 cuts/min |

| Pouch size | Length: 400mm (once feeding) (If length over 400m, by skip feeding) Width: Three side sealing: 55-400mm Center sealing: 80-350mm Width side gusset: 10-70 mm |

| Power requested | Total: 15 kw |

| Main motor (frequency inverter supplied by Panasonic) | |

| Servo motor for feeding material | |

| Unwinding motor | |

| Heating plate for center sealing | |

| Heating plate for cross sealing | |

| Heating plate for forming | |

| Cooling water | 10 liter/min |

| Overall dimension | 8200mmx1000mmx1600mm |

| Total weight | 3000kg |

B. Feature of Automatic Pouch Making Machine :1. Operated by touching screen and all the specificationsare shown on it.2. With “Panasonic” PLC function, it can not only set upvarious data including length, temperature, counting, punching, multiplefeeding etc, but also avoid maintaining and repairing and preventing frominterfering.3. Possess the function of punching with design, removing static electricity,alarming trouble, max. speed limitation, error sizedisplay and cooling temperature display.4. With double servo feeding and doublefrequency conversion for adjusting speed, it is efficient in setting up lengthand position, adjusting speed, as well as tension controlling.5. Unwindingmaterial is controlled by magnetic powder brake which can well control thetension of material, and at the same time it is also controlled by EPC whilemaking gusset bag, available for sealing after forming.6. Generally speaking,resealing type and pressure type are for vertical sealing and lifting, whilemultiple feeding type is for cross sealing. C. Main Structureof Automatic Pouch Making Machine :

| Items | Description |

| Chief motor | Made in china |

| Unwinding motor | Made in china |

| Frequency inverter | Japan Panasonic |

| Electricity control system | Panasonic PLC & NAIS touching screen |

| Photo-electric detector | Welen from Taiwan |

D. Standard Accessories of Automatic PouchMaking Machine :

| Items | Description |

| Cutting knife | 1 pc |

| Heating plate: (840mm 1 pc, 450mm 1 pc, 510mm 1pc) | 3 pcs |

| Forming plate for center sealing (100mm, 150mm, 200mm, 250mm, 300mm) | 5 pcs |

| Tools | 1 set |

| Pressure wheel for forming center sealing bag | 1 set |

| Servo belt | 1 set |

High quality bag making machine,rotogravure printing machine are available.

Links:https://www.globefindpro.com/products/97583.html

-

Air Compressor

Air Compressor

-

ASB1 Automatic Pouch/Bag Making Machine (Double Servo)

ASB1 Automatic Pouch/Bag Making Machine (Double Servo)

-

Crankshafts

Crankshafts

-

Bag Making Machine

Bag Making Machine

-

ASB6 Automatic Pouch/Bag Making Machine (Three Servo)

ASB6 Automatic Pouch/Bag Making Machine (Three Servo)

-

ASB2 Automatic Pouch/Bag Making Machine (Double Servo)

ASB2 Automatic Pouch/Bag Making Machine (Double Servo)

-

Connecting Rods, Fuel System, Piston, Camshaft

Connecting Rods, Fuel System, Piston, Camshaft

-

Engine Maintenance Equipment

Engine Maintenance Equipment

-

Starters

Starters

-

Cylinder Head

Cylinder Head

-

Side Sealing and Cutting Bag Making Machine

Side Sealing and Cutting Bag Making Machine

-

Pharmaceutical Asepsis Pouch Making Machine (Double Servo)

Pharmaceutical Asepsis Pouch Making Machine (Double Servo)