ASB6 Automatic Pouch/Bag Making Machine (Three Servo)

ASB6 Automatic Pouch/Bag Making Machine(Three Servo)

Usage of Automatic Pouch/Bag Making Machine (Three Servo):

This high speed pouch/bag making machine is specialized in producing three sidesealing pouch/bag and stand up pouch (bottom folded with same layer), as wellas three side sealing pouch with zipper and stand up pouch with zipper, whosematerial is with laminated plastic film such as B BOPP/PE, PET/PE, Nylon/PE,BOPP/AL/PE, Paper/PE,BOPP/CPP,PET/CPP, Nylon/CPP,BOPP/AL/CPP etc. With highstandard and quality, this machine is widely used in making solid and liquidpouch and bags for food package area and other industrial package field. It isequipped with double servo, controlled by PLC and operated through the touchingdisplay screen. And we have received the “CE” certificate as for this machine.

A. Technical Parameters of Automatic Pouch/Bag Making Machine (Three Servo):

| Items | Description | |

| Material width | 1200mm | |

| Material diameter | 600mm | |

| Bag type | 3 side sealing bag Gusset type stand up bag Gusset type stand up bag with zipper | |

| Size of making bag | Three side sealing | Height 60-600mm Width 50-300mm (Width is 300mm, available for skip feeding, Max. six times skip feeding) |

| Stand up bag with zipper | Height 40-500mm Width 50-300mm (Width is 300mm, available for skip feeding, Max. six times skip feeding) Depth of bottom gusset Max 65mm Zipper position Adjustable | |

| Bag-making speed | Three side sealing | 30-160pcs/min |

| Gusset type stand up bag & with zipper | 30-140pcs/min | |

| Feeding speed | ≤35m/min | |

B.Main Structure of Automatic Pouch/BagMaking Machine (Three Servo):

| Items | Description | |

| Chief motor (sew) | 3000w 1 pc | |

| Servo motor driving (Panasonic) | 3 sets | |

| Unwinding forming | Triangle folding type | |

| Unwinding motor | 250w 1 pc | |

| Photocell for colorful mark | 1 pc | |

| Photocell for EPC | 2 pcs | |

| EPC controller | 1 pc | |

| PLC temperature controller | ||

| Heating of crossing direction sealing (640x60mm) | 4 sets | |

| Cooling of crossing direction sealing (640x60mm) | 1 set | |

| Heating of machine direction sealing (640x60mm) | 4 sets | |

| Cooling of machine direction sealing (510x60mm) | 4 sets | |

| Punch device (for hanging hole and tearing) | 2 sets | |

| Punch device for stand up pouch | 1 set | |

| Auto tension control: Mitsubishi magnetic powder braker | 1 pc | |

| Rotary coder from Sino-Japan | 1 pc | |

| Frequency conversion for unwinding “Panasonic” | 1 pc | |

| Waste film rewinder | 1 pc | |

| Electric control | “Panasonic” PLC with 10.4 colorful touching screen | |

| Accessories of zipper device | Rack of zipper device | 1 set |

| Zipper heating: (2000w x 2 =4000w) | 1set | |

| Zipper cooling: | 1 set | |

| Guide of inserting zipper | 1 set | |

| Zipper heating plate | 1 set | |

| Zipper spot heating: (up and down) | 1 set | |

| Zipper spot heating plate: (up and down) | 1 set | |

| Cross rack of zipper heating (adjustable) | 1 set | |

| Zipper heating Cushion | 1 set | |

| Zipper heating blade | 1 set | |

| Overall dimension(L×W×H) | 12500x2200x1690mm | |

| Weight | about 4500 kg | |

C. Standard accessories of AutomaticPouch/Bag Making Machine (Three Servo):

| Items | Description |

| Up and down blade | 1 set |

| Synchronous belt | 2 pcs |

| Magnetic valve | 2 pcs |

| Pressure-reduced valve | 2 pcs |

| Thermocouple | 2 pcs |

| Fuse | 10 pcs |

| Temperature controller | 1 pc |

| Approach switch | 1 pc |

| Tool | 1 set |

| Heating knife (30mm, 40mm, 50mmx640mm) | 3 sets |

| “K” seal bottom sealing knife (adjustable) | 1 set |

D. Optional parts of Automatic Pouch/Bag MakingMachine (Three Servo):

1.Three holes handle punching device

2. Banana shape handle punching device

3. Butterfly punch device

4. Shaped round bottom forming knife

(Making stand up bag look like with bottom inserted by separate layer)

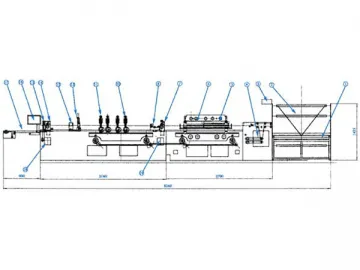

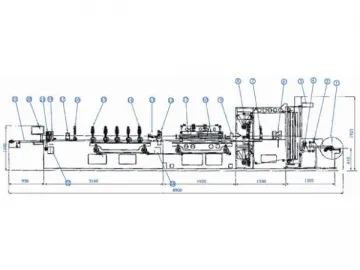

1. Web film

2. K type unwind plate

3. E.P.C

4. Dancing roll of tension

5. Longitudinal sealing unit

6. Longitudinal cooling unit

7. Feed roll

8. Compensate roll of tension

9. Cross sealing unit

10. Cross cooling unit

11. Punching unit

12. Photo eye sensor

13. Feed roll

14. Slitting blade

15. Electric control unit

16. Conveyor and working table

17. Servo motor for feeding

18. Servo motor for feeding

High quality bag making machine, rotogravure printingmachine are available.

Links:https://www.globefindpro.com/products/97589.html

-

ASB2 Automatic Pouch/Bag Making Machine (Double Servo)

ASB2 Automatic Pouch/Bag Making Machine (Double Servo)

-

Automatic Pouch Making Machine (Double Servo)

Automatic Pouch Making Machine (Double Servo)

-

Turbocharger

Turbocharger

-

Diaper Bag Making Machine

Diaper Bag Making Machine

-

Compute-Controlled Paper-Towel Bag Making Machine

Compute-Controlled Paper-Towel Bag Making Machine

-

Cylinder Block

Cylinder Block

-

Bag Making Machine

Bag Making Machine

-

Crankshafts

Crankshafts

-

ASB1 Automatic Pouch/Bag Making Machine (Double Servo)

ASB1 Automatic Pouch/Bag Making Machine (Double Servo)

-

Air Compressor

Air Compressor

-

ASB5 Automatic Pouch Making Machine

ASB5 Automatic Pouch Making Machine

-

Connecting Rods, Fuel System, Piston, Camshaft

Connecting Rods, Fuel System, Piston, Camshaft