ASB2 Automatic Pouch/Bag Making Machine (Double Servo)

ASB2 Automatic Pouch/Bag Making Machine(Double Servo)

Description of (Double Servo) Automatic Pouch/Bag Making Machine:

Equipped with double servo, PLC controller and the touchingdisplay screen operation system, this high speed pouch/bag making machine canproduce three side sealing bags with laminated plastic film such as BOPP/PE,PET/PE, Nylon/PE, BOPP/AL/PE, Paper/PE, BOPP/CPP, PET/CPP, Nylon/CPP,BOPP/AL/CPP etc. This high standard and quality bag-making machine is widelyused in making solid and liquid pouch and bags for food package area and otherindustrial package field. And also we have received the “CE” certificate as forthis machine.

A. Technical Specifications of (Double Servo) AutomaticPouch/Bag Making Machine:

| Items | Description | |

| Material width | 1200mm | |

| Material diameter | 600mm | |

| Bag type |

|

|

| Three side sealing bag | Bag length: 50-550mm (If over 300mm, feeding by skip, Max. 6 times feeding) Bag width: 60-600mm Bag-makin speed:35-160pcs/min Feeding speed: 35m/min | |

| Stand up bag | Bag width: 60-250mm Bag length: 120-270mm (two lines), 540mm (one line) Bag-making speed : 35-100 cut/min Size of bottom folding : 20-35mm Diameter of bag hole : 12-15mm Main material Diameter : Max 600mm Width: Max 1100mm Folding material Diameter: Max 400mm Width: 40-70mm Max weight: 30 kg Un-winding speed : less than 25m/min | |

| Total power | 52 kw | |

| Overall dimension | 9080x2100x1860mm | |

| Weight | 4600 kg | |

B.Main Structure of (Double Servo)Automatic Pouch/Bag Making Machine:

| Items | Description | |

| Chief motor (sew) | 3000w | |

| Servo motor driving | 2 sets (1-1.5kw) | |

| Main unwinding motor | 250w | |

| Main motor (Panasonic frequency conversion) | 3000w | |

| Main unwinding (Panasonic frequency conversion) | 400w | |

| Unwinding motor for stand up bag | 2 sets (180 w) | |

| Unwinding for stand up ba | 2 sets (400w) | |

| Auto tension control | “Mitsubishi “magnetic powder brake & rotary coder | |

| EPC for unwinding film | by double photocell | |

| Temperature controller (pc) | 16 sets | |

| Heating of crossing direction sealing | 4 sets | |

| Cooling of crossing direction sealing | 1 set | |

| Heating of machine direction sealing | 4 sets | |

| Cooling of machine direction sealing | 4 sets | |

| Punching device | 4 sets | |

| Waste film winder | 2 units | |

| Electric control | by “NASI” PLC with touching screen | |

| Accessories of stand up pouch device | Rack of stand up bag | 1 set |

| Double-swing rod | 1 set | |

| Bottom film unwinding device | 2 sets | |

| Folding device | 2 sets | |

| Quide plate | 2 sets | |

| Cross heating and spot heating | 2 pcs/each | |

| “R” type heating blade | 4 pcs | |

| Punch device of bottom folding | 2 sets | |

C. Standard Accessories of (Double Servo)Automatic Pouch/Bag Making Machine:

| Items | Description |

| Up And down blade | 1 set |

| Synchronous belt | 2 pcs |

| Magnetic valve | 2 pcs |

| Pressure-reduce valve | 2 pcs |

| Thermocouple | 2 pcs |

| Fuse | 10 pcs |

| Temperature controller | 1 pc |

| Approaching switch | 1 pc |

| Tool | 1 set |

| Heating knife (30mm,40mm,50mmx640mm) | 3 sets |

D. Optional Parts Automatic Pouch/BagMaking Machine (Double Servo):

Double cutting system for corner cutting

(With extra double servo control system and one waste film adsorber )

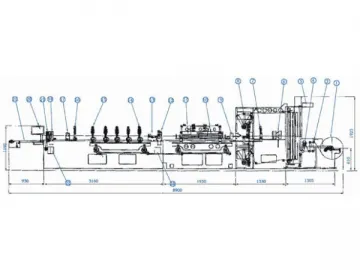

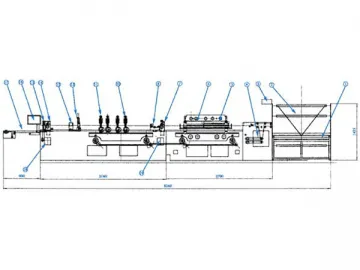

1. Main web

2. Coder

3. Tension roll

4. Rewind roll

5. E.P.C

6. Folding tape unit Dancing roll of tension

7. Bottom type punching unit Slitting unit

8. Dual dancing roll

9. Photo eye sensor

10. Longitudinal sealing unit

11. Longitudinal cooling unit

12. Feeding roll

13. Compensate roll for tension

14. Cross sealing unit

15. Cross cooling unit

16. Punching unit

17. Photo eye sensor

18. Feeding roll

19. Slitting blader

20. Electric control unit

21. Conveyor

22. Servo motor for feeding

23. Servo motor for feeding

24. Servo motor for feeding

High quality bag making machine, rotogravure printing machine are available.

Links:https://www.globefindpro.com/products/97590.html

-

Automatic Pouch Making Machine (Double Servo)

Automatic Pouch Making Machine (Double Servo)

-

Turbocharger

Turbocharger

-

Diaper Bag Making Machine

Diaper Bag Making Machine

-

Compute-Controlled Paper-Towel Bag Making Machine

Compute-Controlled Paper-Towel Bag Making Machine

-

Cylinder Block

Cylinder Block

-

Seals & Gaskets (Oil Seal & Gasket Set)

Seals & Gaskets (Oil Seal & Gasket Set)

-

ASB6 Automatic Pouch/Bag Making Machine (Three Servo)

ASB6 Automatic Pouch/Bag Making Machine (Three Servo)

-

Bag Making Machine

Bag Making Machine

-

Crankshafts

Crankshafts

-

ASB1 Automatic Pouch/Bag Making Machine (Double Servo)

ASB1 Automatic Pouch/Bag Making Machine (Double Servo)

-

Air Compressor

Air Compressor

-

ASB5 Automatic Pouch Making Machine

ASB5 Automatic Pouch Making Machine