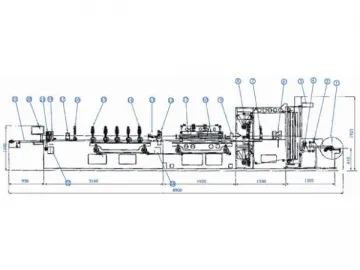

Diaper Bag Making Machine

Diaper Bag Making Machine

Usage of Baby Diaper Bag Making Machine :

With CPU integrated control and LCD keyboard type of operating system and thefunction of inserting the extra layer on the part of handle punching toreinforce handle part of the bags, this bag-making is special for making bottomsealing bags with HDPE and LDPE hot sealable film, and it is widely used inmaking the baby diaper bags, sanitary towel bags, gift bags as well as shoesbags etc.

Features of Baby Diaper Bag Making Machine :

The main features of this kind of bag-making machine are as followed:

1. With function of automatically counting, stopping and starting when reachingthe set meters, it is controlled by computer and operated by LCS (liquidcrystal screen).

2. The working temperature is controlled by meters and the adjustabletemperature range is from 0-400 degree.

3. The temperature of the sealing point in the sealing knife can be adjustedseparately, and the sealing position can be also adjusted.

4. The main feeding system is controlled by 1.5 kwPanasonic servo motor and driven through the synchronic belt.

5. The unwinding is controlled by photocell and adjusted by current volumeswitch, and driven by 300W DC motor.

6. One set of pneumatic control hot punching device for handle with two extramoulds, of which one is banana-shape and the other is two- finger shape.

7. For printing film, it is detected by photocell model KT-5 from Germany.

8. Equipped with 1 set of anti-static device and 2 rods.

9. Equipped with step motor for feeding inserting extra layer, the machine iscontrolled by separate computer.

Main Technical Parameter Baby Diaper Bag Making Machine :

| Items | Description |

| Max. bag width | 100-650mm |

| Max. mechanical speed | 130 cuts/min |

| Max. bag length | 100-800mm |

| Total power | about 4.5 kw |

| Max. unwinding diameter | 600mm |

| Overall dimension | 3800x1500x1600 mm |

| Max. working speed | 3000mm/min |

| Weight | 1000 kg |

Links:https://www.globefindpro.com/products/97593.html

-

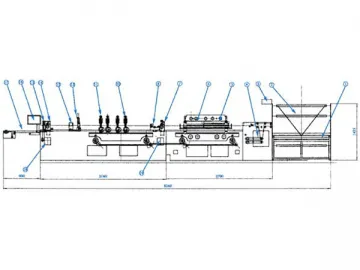

Compute-Controlled Paper-Towel Bag Making Machine

Compute-Controlled Paper-Towel Bag Making Machine

-

Cylinder Block

Cylinder Block

-

Seals & Gaskets (Oil Seal & Gasket Set)

Seals & Gaskets (Oil Seal & Gasket Set)

-

ABS8 Lamination Machine

ABS8 Lamination Machine

-

Fuel Injection Pump

Fuel Injection Pump

-

Alternators

Alternators

-

Turbocharger

Turbocharger

-

Automatic Pouch Making Machine (Double Servo)

Automatic Pouch Making Machine (Double Servo)

-

ASB2 Automatic Pouch/Bag Making Machine (Double Servo)

ASB2 Automatic Pouch/Bag Making Machine (Double Servo)

-

ASB6 Automatic Pouch/Bag Making Machine (Three Servo)

ASB6 Automatic Pouch/Bag Making Machine (Three Servo)

-

Bag Making Machine

Bag Making Machine

-

Crankshafts

Crankshafts