Forced Circulation Evaporator

Forced CirculationEvaporator

Forced circulation evaporator, a perfectexpress of competitiveness and reliability, has brought us a worldwideprestige. Originally designed for tomato pastes, our forced circulationevaporators are also widely used in viscous liquid concentrating. It canefficiently produce products with high concentration values and ideal organoleptic characteristics.

In our forced circulation evaporator, viscous liquids andproducts with suspended solids like fruit and vegetable pulp is pumped throughvertical or horizontal heating elements and circulates in the system underpressure. When the products reach the separating chamber, vapor flashingoccurs. Single effect, twin effects, triple effects or multi-effect forcedcirculation evaporators are all available for different capacity and energysaving requirements.

Featuresand Advantages

1. Our forced circulation evaporator has reducedholding time, especially at higher concentration.

2. Whether it is single effect, twin effects or triple effects, thetemperatures are very low.

3. It has very high circulating speed in all the stages, resulting in minimizedthermal damage to the product during the heating phase.

4. By using multi-effect machines, the steam and water consumption is reduced.

5. It has high absolute precision while measuring the optical index of paste.

6. Its high-performance recirculation pumps are specially designed and testedfor operation even in the worst working conditions.

7. The pumps run easily thanks to the unique inclined design for heatingchamber.

8. This forced circulation evaporator carries out high final concentration,owing to excellent performance of the recirculation pumps and fast product flowinside the tube nests. For example, up to 32°Bx with Hot Break paste and36-38°Bx with Cold Break paste.

9. Juice deaeration during concentration is alsoavailable.

10. It is fitted with touch screen color video and connected to a PLC. With adesk top PC, retrofit line management can take placeeasily.

Parameters

Forced External Circulating Concentrator,Double Effect

| Model | SD-2100 | SD-5300 |

| Evaporating capacity (l/h) | 2100 | 5300 |

| Dimension (mm) | 5450×5635×7800 | 6500×5300×8900 |

| Water (kg/h) | 800 | 800 |

| Power (kw) | 44.5 | 95 |

| Steam (kg/h) | 1150 | 2900 |

| Compressed air (m3/h) | 0.1 | 0.1 |

| Cooling water (tons/h) | 110 | 292 |

Forced External Circulating Concentrator,Triple Effect

| Model | SDF9200 | SDF18300 | SDF26000 | SDF35000 | SDF44000 | SDF53000 |

| Evaporation capacity (t/h) | 9.2 | 18.3 | 26 | 35 | 44 | 53 |

| Dimension (mm) | 12000×6000 ×13000 | 13400×6500 ×11500 | 16900×7100 ×14200 | 17300×7100 ×15900 | 16900×7100 ×14200 | 18450×8059 ×15525 |

| Water (t/h) | 1.2 | 2.7 | 4 | 2.7 | 4 | 4 |

| Power (kw) | 330 | 406 | 648.5 | 897 | 963 | 1040 |

| Steam (t/h) | 3.6 | 6.6 | 10.42 | 13.7 | 17.2 | 20.17 |

| Compressed air (m3/h) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Cooling water (t/h) | 272 | 545 | 785 | 1035 | 1365 | 1570 |

We are a professional forced circulation evaporatormanufacturer, founded in 1990. Located in China, we enjoy easy access totransportation facilities by land, sea and air. Therefore, we can ship ourtomato paste production lines, transportation receiving equipment, beltpresses, aseptic fillers, aseptic filling machines and more products at reducedcosts. With high quality and low prices, these fruit processing lines andcomponents are ideal choices for you. You are welcome to contact us for moreinformation!

Links:https://www.globefindpro.com/products/97654.html

-

Graphite Thrust Bearings

Graphite Thrust Bearings

-

ASB17 Paper Slitting Machine

ASB17 Paper Slitting Machine

-

Graphite Plate A

Graphite Plate A

-

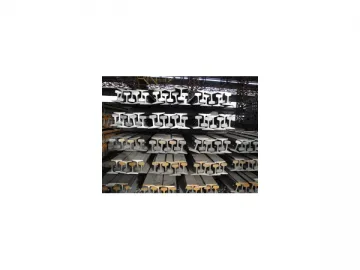

UIC Standard Rails

UIC Standard Rails

-

SA Standard Rails

SA Standard Rails

-

Automatic High Speed Label Cutting Machine

Automatic High Speed Label Cutting Machine

-

ASB10 Automatic Slitting Machine

ASB10 Automatic Slitting Machine

-

Fruit Washing Sorting Equipment

Fruit Washing Sorting Equipment

-

Double-shaft Surface-rewinding Slitting Machine

Double-shaft Surface-rewinding Slitting Machine

-

Graphite Gasket

Graphite Gasket

-

High Speed PVC Sleeve Inspection Machine

High Speed PVC Sleeve Inspection Machine

-

ASB18 Automatic Slitting Machine

ASB18 Automatic Slitting Machine